connecting rods on:

[Wikipedia]

[Google]

[Amazon]

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the

The predecessor to the connecting length is the

The predecessor to the connecting length is the

A connecting rod for an internal combustion engine consists of the 'big end', 'rod' and 'small end'. The small end attaches to the

A connecting rod for an internal combustion engine consists of the 'big end', 'rod' and 'small end'. The small end attaches to the

During each rotation of the crankshaft, a connecting rod is often subject to large and repetitive forces: shear forces due to the angle between the piston and the crankpin,

During each rotation of the crankshaft, a connecting rod is often subject to large and repetitive forces: shear forces due to the angle between the piston and the crankpin,

Fork-and-blade rods, also known as "split big-end rods", have been used on

Fork-and-blade rods, also known as "split big-end rods", have been used on

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth linear motion. It is found in a wide range of mechanisms, including reciprocating engines and pumps. The two opposite motions that comprise a single r ...

of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal c ...

, it allows pivoting on the piston end and rotation on the shaft end.

The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion.

The most common usage of connecting rods is in internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal c ...

s or on steam engines.

__TOC__

Origins

mechanical linkage

A mechanical linkage is an assembly of systems connected to manage forces and movement. The movement of a body, or link, is studied using geometry so the link is considered to be rigid. The connections between links are modeled as providing i ...

used by Roman-era watermills. The earliest known example of this linkage has been found at the late 3rd century Hierapolis sawmill

The Hierapolis sawmill was a Roman water-powered stone sawmill at Hierapolis, Asia Minor (modern-day Turkey). Dating to the second half of the 3rd century AD, the sawmill is considered the earliest known machine to combine a crank with a connect ...

in Roman Asia (modern Turkey) and the 6th century saw mills at Ephesus in Asia Minor (modern Turkey) and at Gerasa

Jerash ( ar, جرش ''Ǧaraš''; grc, Γέρασα ''Gérasa'') is a city in northern Jordan. The city is the administrative center of the Jerash Governorate, and has a population of 50,745 as of 2015. It is located north of the capital cit ...

in Roman Syria. The crank and connecting rod mechanism of these machines converted the rotary motion of the waterwheel into the linear movement of the saw blades.

An early documentation of the design occurred sometime between 1174 and 1206 AD in the Artuqid State (modern Turkey), when inventor Al-Jazari described a machine which incorporated the connecting rod with a crankshaft to pump water as part of a water-raising machine, though the device was more complex than typical crank and connecting rod designs. There is also documentation of cranks with connecting rods in the sketch books of Taccola

Mariano di Jacopo (1382 – c. 1453), called Taccola (" the jackdaw"), was an Italian polymath, administrator, artist and engineer of the early Renaissance. Taccola is known for his technological treatises ''De ingeneis'' and ''De machinis'', wh ...

from Renaissance Italy

The Italian Renaissance ( it, Rinascimento ) was a period in Italian history covering the 15th and 16th centuries. The period is known for the initial development of the broader Renaissance culture that spread across Europe and marked the trans ...

and 15th century painter Pisanello.

Steam engines

The 1712Newcomen atmospheric engine

The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to as the Newcomen fire engine (see below) or simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creati ...

(the first steam engine) used chain drive instead of a connecting rod, since the piston only produced force in one direction. However, most steam engines after this are double-acting, therefore the force is produced in both directions, leading to the use of a connecting rod. The typical arrangement uses a large sliding bearing block called a crosshead with the hinge between the piston and connecting rod placed outside the cylinder, requiring a seal around the piston rod

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels.

Internal combustion engines, and in particular all current automobile engin ...

.

In a steam locomotive, the cranks are usually mounted directly on the driving wheels. The connecting rod is used between the crank pin on the wheel and the crosshead (where it connects to the piston rod

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels.

Internal combustion engines, and in particular all current automobile engin ...

). The equivalent connecting rods on diesel locomotives are called 'side rods' or 'coupling rods'. On smaller steam locomotives, the connecting rods are usually of rectangular cross-section, however marine-type rods of circular cross-section have occasionally been used.

On paddle steamer

A paddle steamer is a steamship or steamboat powered by a steam engine that drives paddle wheels to propel the craft through the water. In antiquity, paddle wheelers followed the development of poles, oars and sails, where the first uses we ...

s, the connecting rods are called 'pitmans' (not to be mistaken for pitman arm

A Pitman arm is a shaft that translates rotary or angular movement into linear movement, or vice versa. Pitman arms are commonly found in water pumping windmills, automotive steering systems, and sewing machines.

In windmills, the Pitman arm con ...

s).

Internal combustion engines

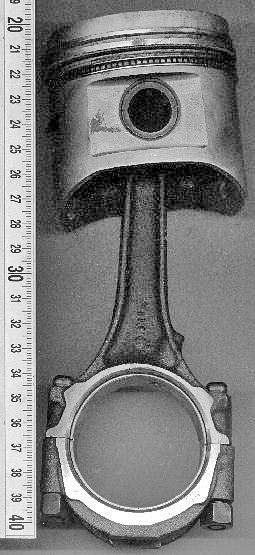

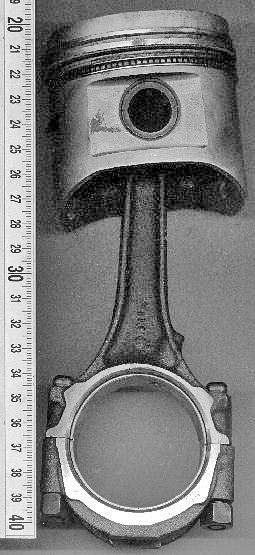

A connecting rod for an internal combustion engine consists of the 'big end', 'rod' and 'small end'. The small end attaches to the

A connecting rod for an internal combustion engine consists of the 'big end', 'rod' and 'small end'. The small end attaches to the gudgeon pin

In internal combustion engines, the gudgeon pin (UK, wrist pin or piston pin US) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.Nunney, Malcolm James (2007) "The Reciproc ...

(also called 'piston pin' or 'wrist pin'), which allows for rotation between the connecting rod and the piston. Typically, the big end connects to the crankpin

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the ...

using a plain bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no roll ...

to reduce friction; however some smaller engines may instead use a rolling-element bearing, in order to avoid the need for a pumped lubrication system. Connecting rods with rolling element bearings are typically a one piece design where the crankshaft must be pressed together through them, rather than a two piece design that can be bolted around the journal of a one piece crankshaft.

Typically there is a pinhole bored through the bearing on the big end of the connecting rod so that lubricating oil squirts out onto the thrust side of the cylinder wall to lubricate the travel of the pistons and piston ring

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine.

The main functions of piston rings in engines are:

# Sealing the combustion chamber so that there is min ...

s.

A connecting rod can rotate at both ends, so that the angle between the connecting rod and the piston can change as the rod moves up and down and rotates around the crankshaft.

Materials

The materials used for connecting rods widely vary, including carbon steel, iron base sintered metal, micro-alloyed steel, spheroidized graphite cast iron. In mass-produced automotive engines, the connecting rods are most usually made of steel. In high performance applications, "billet" connecting rods can be used, which are machined out of a solidbillet

A billet is a living-quarters to which a soldier is assigned to sleep. Historically, a billet was a private dwelling that was required to accept the soldier.

Soldiers are generally billeted in barracks or garrisons when not on combat duty, alth ...

of metal, rather than being cast

Cast may refer to:

Music

* Cast (band), an English alternative rock band

* Cast (Mexican band), a progressive Mexican rock band

* The Cast, a Scottish musical duo: Mairi Campbell and Dave Francis

* ''Cast'', a 2012 album by Trespassers William

...

or forged.

Other materials include T6-2024 aluminium alloy 2024 aluminium alloy is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has av ...

or T651-7075 aluminium alloy

7075 aluminium alloy (AA7075) is an aluminium alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It is more susceptible to ...

, which are used for lightness and the ability to absorb high impact at the expense of durability. Titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

is a more expensive option which reduces the weight. Cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

can be used for cheaper, lower performance applications such as motor scooters.

Failure during operation

During each rotation of the crankshaft, a connecting rod is often subject to large and repetitive forces: shear forces due to the angle between the piston and the crankpin,

During each rotation of the crankshaft, a connecting rod is often subject to large and repetitive forces: shear forces due to the angle between the piston and the crankpin, compression forces

In mechanics, compression is the application of balanced inward ("pushing") forces to different points on a material or structure, that is, forces with no net sum or torque directed so as to reduce its size in one or more directions.Ferdinand ...

as the piston moves downwards, and tensile forces as the piston moves upwards. These forces are proportional to the engine speed (RPM) squared.

Failure of a connecting rod, often called "throwing a rod" often forces the broken rod through the side of the crankcase and thereby rendering the engine irreparable. Common causes of connecting rod failure are tensile failure from high engine speeds, the impact force when the piston hits a valve (due to a valvetrain problem), rod bearing failure (usually due to a lubrication problem), or incorrect installation of the connecting rod.

Cylinder wear

The sideways force exerted on the piston through the connecting rod by the crankshaft can cause the cylinders to wear into an oval shape. This significantly reduces engine performance, since the circularpiston ring

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine.

The main functions of piston rings in engines are:

# Sealing the combustion chamber so that there is min ...

s are unable to properly seal against the oval-shaped cylinder walls.

The amount of sideways force is proportional to the angle of the connecting rod, therefore longer connecting rods will reduce the amount of sideways force and engine wear. However, the maximum length of a connecting rod is constrained by the engine block size; the stroke length plus the connecting rod length must not result in the piston travelling past the top of the engine block.

Master-and-slave rods

Radial engine

The radial engine is a reciprocating type internal combustion engine configuration in which the cylinders "radiate" outward from a central crankcase like the spokes of a wheel. It resembles a stylized star when viewed from the front, and is ...

s typically use master-and-slave connecting rods, whereby one piston (the uppermost piston in the animation), has a master rod with a direct attachment to the crankshaft. The remaining pistons pin their connecting rods' attachments to rings around the edge of the master rod.

Multi-bank engines with many cylinders, such as V12 engine

A V12 engine is a twelve-cylinder piston engine where two banks of six cylinders are arranged in a V configuration around a common crankshaft. V12 engines are more common than V10 engines. However, they are less common than V8 engines.

The f ...

s, have little space available for many connecting rod journals on a limited length of crankshaft. The simplest solution, as used in most road car engines, is for each pair of cylinders to share a crank journal, but this reduces the size of the rod bearings and means that matching (i.e. opposite) cylinders in the different banks are slightly offset along the crankshaft axis (which creates a rocking couple). Another solution is to use master-and-slave connecting rods, where the master rod also includes one or more ring pins which are connected to the big ends of slave rods on other cylinders. A drawback of master-slave rods is that the stroke lengths of all slave pistons not located 180° from the master piston will always be slightly longer than that of the master piston, which increases vibration in V engines.

One of the most complicated examples of master-and-slave connecting rods is the 24-cylinder Junkers Jumo 222

The Jumo 222 was a German high-power multiple-bank in-line piston aircraft engine from Junkers, designed under the management of Ferdinand Brandner of the Junkers Motorenwerke.

Such was the projected performance of the engine compared to con ...

experimental airplane engine developed for World War II. This engine consisted of six banks of cylinders, each with four cylinders per bank. Each "layer" of six cylinders used one master connecting rod, with the other five cylinders using slave rods. Approximately 300 test engines were built, however the engine did not reach production.

Fork-and-blade rods

Fork-and-blade rods, also known as "split big-end rods", have been used on

Fork-and-blade rods, also known as "split big-end rods", have been used on V-twin

A V-twin engine, also called a V2 engine, is a two-cylinder piston engine where the cylinders share a common crankshaft and are arranged in a V configuration.

Although widely associated with motorcycles (installed either transversely or longi ...

motorcycle engines and V12 V12 or V-12 may refer to:

Aircraft

* Mil V-12, a Soviet heavy lift helicopter

* Pilatus OV-12, a planned American military utility aircraft

* Rockwell XFV-12, an American experimental aircraft project

* Škoda-Kauba V12, a Czechoslovak experim ...

aircraft engines. For each pair of cylinders, a "fork" rod is split in two at the big end and the "blade" rod from the opposing cylinder is thinned to fit into this gap in the fork. This arrangement removes the rocking couple that is caused when cylinder pairs are offset along the crankshaft.

A common arrangement for the big-end bearing is for the fork rod to have a single wide bearing sleeve that spans the whole width of the rod, including the central gap. The blade rod then runs, not directly on the crankpin, but on the outside of this sleeve. This causes the two rods to oscillate back and forth (instead of rotating relative to each other), which reduces the forces on the bearing and the surface speed. However the bearing movement also becomes reciprocating rather than continuously rotating, which is a more difficult problem for lubrication.

Notable engines to use fork-and-blade rods include the Rolls-Royce Merlin

The Rolls-Royce Merlin is a British liquid-cooled V-12 piston aero engine of 27-litres (1,650 cu in) capacity. Rolls-Royce designed the engine and first ran it in 1933 as a private venture. Initially known as the PV-12, it was late ...

V12 aircraft engine, EMD two-stroke Diesel engines, and various Harley Davidson Harley may refer to:

People

* Harley (given name)

* Harley (surname)

Places

* Harley, Ontario, a township in Canada

* Harley, Brant County, Ontario, Canada

* Harley, Shropshire, England

* Harley, South Yorkshire, England

* Harley Street, in L ...

V-twin motorcycle engines.

See also

* Hydrolock * Steam locomotive componentsReferences

{{Authority control Engine technology Locomotive parts Turkish inventions Linkages (mechanical)