cerec on:

[Wikipedia]

[Google]

[Amazon]

CAD/CAM dentistry is a field of

CAD/CAM dentistry is a field of

For a single unit prosthesis, after decayed or broken areas of the tooth are corrected by the dentist, an optical impression is made of the prepared tooth and the surrounding teeth. These images are then turned into a digital model by proprietary software within which the prosthesis is created virtually. The software sends this data to a milling machine where the prosthesis is milled. Stains and glazes can be added to the surfaces of the milled ceramic crown or bridge to correct the otherwise monochromatic appearance of the restoration. The restoration is then adjusted in the patient’s mouth and luted or bonded in place.

Integrating optical scan data with cone beam computed tomography datasets within implantology software also enables surgical teams to digitally plan implant placement and fabricate a surgical guide for precise implementation of that plan. Combining CAD/CAM software with 3D images from a 3D imaging system means greater safety and security from any kind of intraoperative mistakes.

For a single unit prosthesis, after decayed or broken areas of the tooth are corrected by the dentist, an optical impression is made of the prepared tooth and the surrounding teeth. These images are then turned into a digital model by proprietary software within which the prosthesis is created virtually. The software sends this data to a milling machine where the prosthesis is milled. Stains and glazes can be added to the surfaces of the milled ceramic crown or bridge to correct the otherwise monochromatic appearance of the restoration. The restoration is then adjusted in the patient’s mouth and luted or bonded in place.

Integrating optical scan data with cone beam computed tomography datasets within implantology software also enables surgical teams to digitally plan implant placement and fabricate a surgical guide for precise implementation of that plan. Combining CAD/CAM software with 3D images from a 3D imaging system means greater safety and security from any kind of intraoperative mistakes.

CAD/CAM dentistry is a field of

CAD/CAM dentistry is a field of dentistry

Dentistry, also known as dental medicine and oral medicine, is the branch of medicine focused on the teeth, gums, and mouth. It consists of the study, diagnosis, prevention, management, and treatment of diseases, disorders, and conditions o ...

and prosthodontics

Prosthodontics, also known as dental prosthetics or prosthetic dentistry, is the area of dentistry that focuses on dental prostheses. It is one of 12 dental specialties recognized by the American Dental Association (ADA), Royal College of Surge ...

using CAD/CAM ( computer-aided-design and computer-aided-manufacturing) to improve the design and creation of dental restoration

Dental restoration, dental fillings, or simply fillings are treatments used to restore the function, integrity, and morphology of missing tooth structure resulting from caries or external trauma as well as to the replacement of such structure sup ...

s, especially dental prostheses

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the den ...

, including crowns

A crown is a traditional form of head adornment, or hat, worn by monarchs as a symbol of their power and dignity. A crown is often, by extension, a symbol of the monarch's government or items endorsed by it. The word itself is used, partic ...

, crown lays, veneers, inlays and onlays, fixed dental prostheses bridges

A bridge is a structure built to Span (engineering), span a physical obstacle (such as a body of water, valley, road, or rail) without blocking the way underneath. It is constructed for the purpose of providing passage over the obstacle, whic ...

, dental implant

A dental implant (also known as an endosseous implant or fixture) is a prosthesis that interfaces with the bone of the jaw or skull to support a dental prosthesis such as a crown, bridge, denture, or facial prosthesis or to act as an orthodonti ...

supported restorations, dentures

Dentures (also known as false teeth) are prosthetic devices constructed to replace missing teeth, and are supported by the surrounding soft and hard tissues of the oral cavity. Conventional dentures are removable (removable partial denture or ...

( removable or fixed

Fixed may refer to:

* ''Fixed'' (EP), EP by Nine Inch Nails

* ''Fixed'', an upcoming 2D adult animated film directed by Genndy Tartakovsky

* Fixed (typeface), a collection of monospace bitmap fonts that is distributed with the X Window System

* ...

), and orthodontic appliances

Orthodontic technology is a specialty of dental technology that is concerned with the design and fabrication of dental appliances for the treatment of malocclusions, which may be a result of tooth irregularity, disproportionate jaw relationships, ...

. CAD/CAM technology allows the delivery of a well-fitting, aesthetic, and a durable prostheses for the patient. CAD/CAM complements earlier technologies used for these purposes by any combination of increasing the speed of design and creation; increasing the convenience or simplicity of the design, creation, and insertion processes; and making possible restorations and appliances that otherwise would have been infeasible. Other goals include reducing unit cost

The unit cost is the price incurred by a company to produce, store and sell one unit of a particular product. Unit costs include all fixed costs and all variable costs

Variable costs are costs that change as the quantity of the good or service ...

and making affordable restorations and appliances that otherwise would have been prohibitively expensive. However, to date, chairside CAD/CAM often involves extra time on the part of the dentist, and the fee is often at least two times higher than for conventional restorative treatments using lab services.

Like other CAD/CAM fields, CAD/CAM dentistry uses subtractive processes (such as CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a p ...

milling) and additive processes (such as 3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

) to produce physical instances from 3D models.

Some mentions of "CAD/CAM" and "milling technology" in dental technology have loosely treated those two terms as if they were interchangeable, largely because before the 2010s, most CAD/CAM-directed manufacturing was CNC cutting, not additive manufacturing, so CAD/CAM and CNC were usually coinstantiated; but whereas this loose/imprecise usage was once somewhat close to accurate, it no longer is, as the term "CAD/CAM" does not specify the method of production except that whatever method is used takes input from CAD/CAM, and today additive and subtractive methods are both widely used.

Application of CAD/CAM in Dentistry

Computer-aided design (CAD) and computer-aided manufacture (CAM) is a process where non-digital data is captured, converted into a digital format, edited as necessary, and subsequently converted back into a physical form with the exact dimensions and materials specified during the digital design process, usually by either3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

or milling. This set of stages is known as a “digital workflow”.

Currently, CAD/CAM is used to provide a machine led means of fabricating dental prostheses

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the den ...

which are used to restore or replace teeth. This is an alternative to the traditional process of prostheses fabrication, where physical techniques are used, such as impressions, to capture the patient data necessary for the laboratory to fabricate the required dental prosthesis.

Before more widespread acceptance of CAD/CAM, the dentist takes an impression of the site that is to be restored. This is then transported to the laboratory where a study model is made. On that model, an imitation of the final design is made using wax – known as a wax up – which represents the size and shape of the finished dental prosthesis. The wax is then encased in an investment mould, burned out and replaced with the desired material as part of lost wax casting

Lost-wax casting (also called "investment casting", "precision casting", or ''cire perdue'' which has been adopted into English from the French, ) is the process by which a duplicate metal sculpture (often silver, gold, brass, or bronze) i ...

. CAD/CAM makes such procedures unnecessary for the impression is recorded digitally and the manufacture of the appliance is accompanied by additive (3D printing

3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety of processes in which material is ...

) or subtractive ( milling) means.

Examples of dental prosthesis that can be manufactured using this system include:

# Study models

# Orthodontic

Orthodontics is a dentistry specialty that addresses the diagnosis, prevention, management, and correction of mal-positioned teeth and jaws, and misaligned bite patterns. It may also address the modification of facial growth, known as dentofacial ...

devices

# Cuspal coverage restorations

# Fixed dental prosthesis

# Veneers

# Removable denture

Dentures (also known as false teeth) are prosthetic devices constructed to replace missing teeth, and are supported by the surrounding soft and hard tissues of the oral cavity. Conventional dentures are removable (removable partial denture or ...

frameworks

# Implant

Implant can refer to:

Medicine

*Implant (medicine), or specifically:

** Brain implant

** Breast implant

**Buttock implant

**Cochlear implant

**Contraceptive implant

**Dental implant

** Fetal tissue implant

**Implantable cardioverter-defibrillator ...

planning and fabrication

History

Although CAD/CAM dentistry was used in the mid-1980s, early efforts were considered a cumbersome novelty, requiring an inordinate amount of time to produce a viable product. This inefficiency prevented its use within dental offices and limited it to labside use (that is, used within dental laboratories). As adjunctive techniques,software

Software is a set of computer programs and associated documentation and data. This is in contrast to hardware, from which the system is built and which actually performs the work.

At the lowest programming level, executable code consists ...

, and materials improved, the chairside use of CAD/CAM

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). Both of these require powerful computers. ''CAD'' software helps designers and draftsmen; ''CAM'' "reduces manpower costs" in the manufactur ...

(use within dental offices/surgeries) increased. For example, the commercialization

Commercialization or commercialisation is the process of introducing a new product or production method into commerce—making it available on the market. The term often connotes especially entry into the mass market (as opposed to entry into ear ...

of Cerec

CAD/CAM dentistry is a field of dentistry and prosthodontics using CAD/CAM ( computer-aided-design and computer-aided-manufacturing) to improve the design and creation of dental restorations, especially dental prostheses, including crowns, c ...

by Sirona

In Celtic polytheism, Sirona was a goddess worshipped predominantly in East Central Gaul and along the Danubian limes. A healing deity, she was associated with healing springs; her attributes were snakes and eggs. She was sometimes depicted with A ...

made CAD/CAM available to dentists who formerly would not have had avenues for using it.

The article ''CEREC CAD/CAM in Dentistry'' original dissertation Data capture stabilizing device for the CEREC CAD/CAM chairside camera fully explains all pros and cons of the system and is detailed in (materials, fit, software, hardware, etc.).

The first CAD/CAM system used in dentistry was produced in the 1970’s by Duret and colleagues. The process contains a number of steps. Firstly, an optical impression of the intraoral abutment is obtained by scanning with an intra-oral digitizer. The digitized information is transferred to the monitor where a 3D graphic design is produced. The restoration can then be designed on the computer. The final restoration is then milled from a block. Duret and colleagues subsequently developed the ‘sopha system’ however this was not widely used, perhaps lacking the accuracy, materials and computer capabilities required in dentistry. The second generation of CADCAM attempted to develop this system further, but struggled to obtain occlusal morphology using an intra oral scanner, so prepared a stone model first before digitising the model.

Development of a various digitizers followed: a laser beam with a position sensitive detector sensor, a contact probe and a laser with a charged coupled device camera. Due to development of more sophisticated CAD/CAM systems both metal and ceramic restorations could be produced.

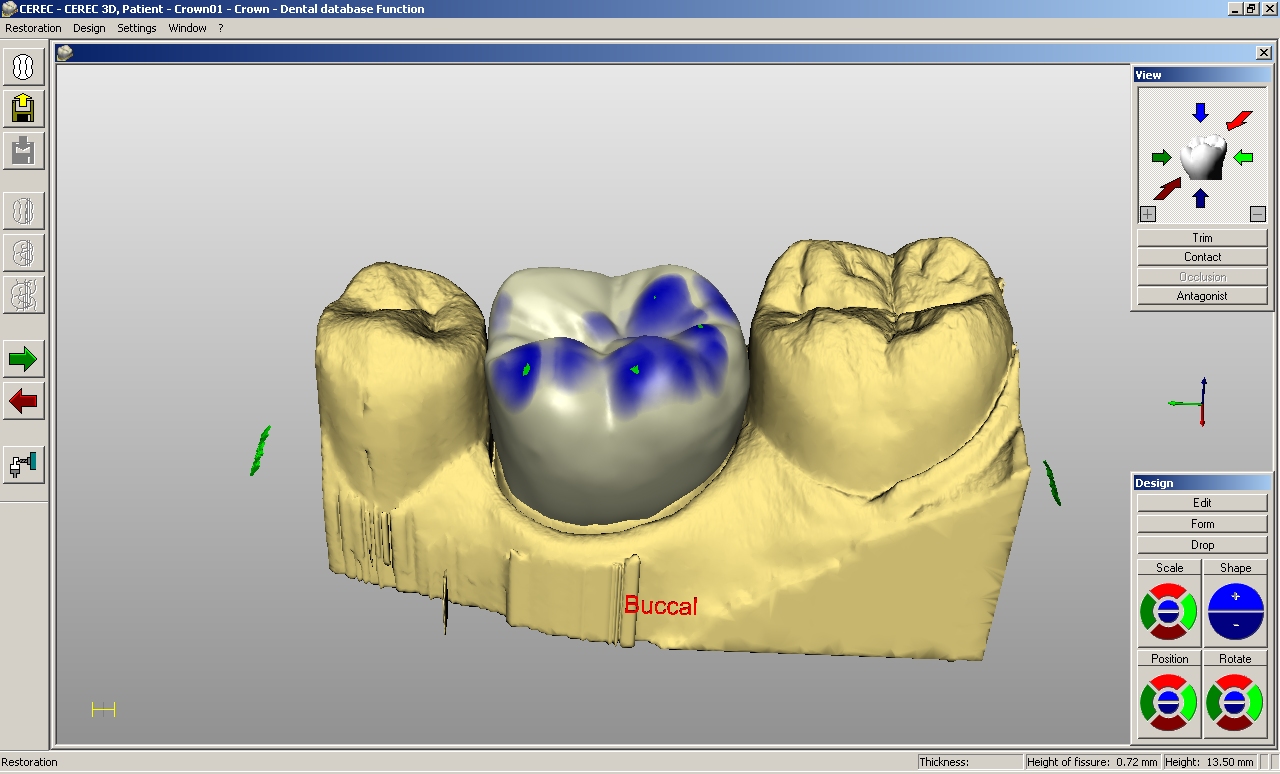

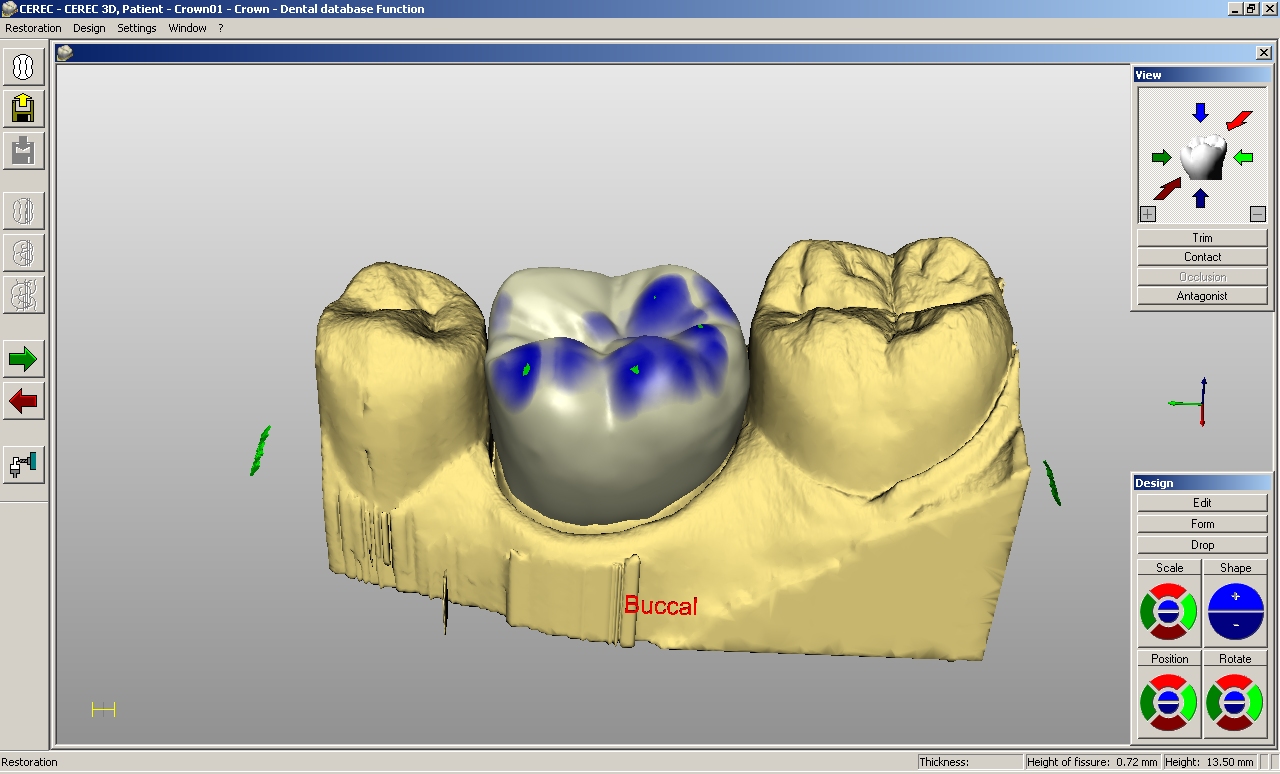

Mormann and colleagues later developed a CADCAM system named CEREC, which they used to produce a type of dental restoration called an inlay. The inlay preparation is scanned using an intra-oral camera. A compact machine used chairside allowed design of the restoration from a ceramic block. The major advantage of this system was the chair side approach allowing same-day restorations. However, this technique was limited in that it couldn’t be used for contouring or occlusal patterns. The CEREC system is used widely across the world, and studies have shown long term clinical success.

The Procera system was developed by Anderson and colleagues. They used CADCAM to develop composite veneers. The Procera system later developed as a processing centre connected to satellite digitisers worldwide to produce all ceramic frameworks. This system is used around the world today.

Difference from conventional restoration

Chairside CAD/CAM restoration typically creates and lutes(bonds) theprosthesis

In medicine, a prosthesis (plural: prostheses; from grc, πρόσθεσις, prósthesis, addition, application, attachment), or a prosthetic implant, is an artificial device that replaces a missing body part, which may be lost through trau ...

the same day. Conventional prostheses, such as crowns, have temporaries placed for one to several weeks while a dental laboratory or in-house dental lab produces the restoration. The patient returns later to have the temporaries removed and the laboratory-made crown cemented or bonded in place. An in-house CAD/CAM system enables the dentist to create a finished inlay in as little as one hour. CAD/CAM systems use an optical camera to take a virtual impression by creating a 3D image which is imported into a software program and results in a computer-generated cast on which the restoration is designed.

Bonded veneer CAD/CAM restorations are more conservative in their preparation of the tooth. As bonding is more effective on tooth enamel than the underlying dentin

Dentin () (American English) or dentine ( or ) (British English) ( la, substantia eburnea) is a calcified tissue of the body and, along with enamel, cementum, and pulp, is one of the four major components of teeth. It is usually covered by ena ...

, care is taken not to remove the enamel layer. Though one-day service is a benefit that is typically claimed by dentists offering chairside CAD/CAM services, the dentist's time is commonly doubled and the fee is therefore doubled.

Process

All CAD/CAM systems consist of a computer aided design (CAD) and computer aided manufacture (CAM) stage and the key stages can broadly be summarised as the following: # Optical/contat scanning that captures the intraoral or extraoral condition of the patient. # Use of software that can turn the captured images into a digital model to upon which a dental prosthesis can be designed and prepared for fabrication. # Instruction to devices that can facilitate the conversion of the design into a product by way of 3D printing of milling depending on the CAD/CAM system used. For a single unit prosthesis, after decayed or broken areas of the tooth are corrected by the dentist, an optical impression is made of the prepared tooth and the surrounding teeth. These images are then turned into a digital model by proprietary software within which the prosthesis is created virtually. The software sends this data to a milling machine where the prosthesis is milled. Stains and glazes can be added to the surfaces of the milled ceramic crown or bridge to correct the otherwise monochromatic appearance of the restoration. The restoration is then adjusted in the patient’s mouth and luted or bonded in place.

Integrating optical scan data with cone beam computed tomography datasets within implantology software also enables surgical teams to digitally plan implant placement and fabricate a surgical guide for precise implementation of that plan. Combining CAD/CAM software with 3D images from a 3D imaging system means greater safety and security from any kind of intraoperative mistakes.

For a single unit prosthesis, after decayed or broken areas of the tooth are corrected by the dentist, an optical impression is made of the prepared tooth and the surrounding teeth. These images are then turned into a digital model by proprietary software within which the prosthesis is created virtually. The software sends this data to a milling machine where the prosthesis is milled. Stains and glazes can be added to the surfaces of the milled ceramic crown or bridge to correct the otherwise monochromatic appearance of the restoration. The restoration is then adjusted in the patient’s mouth and luted or bonded in place.

Integrating optical scan data with cone beam computed tomography datasets within implantology software also enables surgical teams to digitally plan implant placement and fabricate a surgical guide for precise implementation of that plan. Combining CAD/CAM software with 3D images from a 3D imaging system means greater safety and security from any kind of intraoperative mistakes.

Computer Aided Design (CAD)

To design and manufacture adental prosthesis

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the denta ...

, the physical space which it will replace within the mouth has to be converted into a digital format. To do this, a digital impression must be taken. This will convert the space into a digital image which must then be converted into a file extension that can be read by the CAD software system being used.

Once in a digital form, the structures within the mouth will be displayed as a 3D image. Using CAD software, the size and shape of the restoration can be virtually altered, thus replacing the wax up stage present in the traditional approach.

Digital Impressions

Digital impressions are a means of recording the shape of a patient’s dental structures by using scanners. In CAD/CAM’s infancy desktop scanners were used which digitised study models ordental impressions

A dental impression is a negative imprint of hard (teeth) and soft tissues in the mouth from which a positive reproduction (cast or model) can be formed. It is made by placing an appropriate material in a stock or custom dental impression tray w ...

- indirect representations of the patient’s dentition. These devices are also known as extra oral scanners and can be contact or non-contact.

Contact scanners use stylus profilometers which are placed against and run along the contours of an object. The contact of the stylus against the object is represented digitally as a set of co-ordinates (point cloud

Point or points may refer to:

Places

* Point, Lewis, a peninsula in the Outer Hebrides, Scotland

* Point, Texas, a city in Rains County, Texas, United States

* Point, the NE tip and a ferry terminal of Lismore, Inner Hebrides, Scotland

* Point ...

) which is analysed by an onboard mathematical algorithm to build up a 3D image of the object (mesh).

Non-contact scanners capture the shape of dental structures by using optics, such as light-emitting diodes. Light is emitted from the scanner which hits the object and then reflects into an onboard sensor, usually a charge couple device (CCD) or a position sensing detector (PSD). These reflections allow the scanner to build up a 3D image of the object as with contact scanners . Extraoral non-contact scanners can obtain this information by different means, namely: structured light, laser light and confocal microscopy . Contact scanners are more accurate than non-contact scanners but are rarely used anymore because of how slow they are. As well as this, the accuracy necessary for a dental prosthesis to be successful is 10 times less than what these scanners provide, making them excessive.

Intra-oral scanners are a form of non-contact scanners that have grown in popularity due to their ability to digitise a patient’s dentition directly in the mouth which avoids the need for a plaster study model to be made or a conventional dental impression to be taken first, as is the case with extraoral scanners. This allows the fabrication of dental prostheses to be a completely digital process from the very first stage. Older scanners require a contrast powder to be placed on all the structures which were to be scanned whereas newer products do not require such a step.

There are several systems by which intra oral scanners interpret the reflected light to produce a 3D image representing the patient’s teeth. These systems include:

# Confocal laser scanner microscopy

# Triangulation

In trigonometry and geometry, triangulation is the process of determining the location of a point by forming triangles to the point from known points.

Applications

In surveying

Specifically in surveying, triangulation involves only angle me ...

# Optical coherent tomography

# Accordion fringe interferometry

# Active wavefront sampling

The file extension most recognised by CAD software is an STL file. This file type records and describes an object’s geometry as a series of connected triangles, the density of which, depends upon the “resolution and the mathematical algorithm that was used to create the data”. Most available scanners will produce STL files however some produce proprietary file types that can only be interpreted by select CAD software.

CAD Software

CAD software visualises the digital impression captured by extra or intra oral scanners and provides numerous design tools. Popular software packages include Dental System, DentalCAD and CEREC. Some of the most common ways in which the virtual dental prosthesis can be edited are as follows: * The size and shape of restorations can be adjusted. * The shape of teeth is often adjusted using dental burs prior to scanning to accommodate a dental prosthesis such as a crown. This is called a preparation and the edge of this is known as the margin. Margins need to be demarcated so that thedental prosthesis

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the denta ...

finishes flush with the rest of the tooth to reduce the chances of plaque

Plaque may refer to:

Commemorations or awards

* Commemorative plaque, a plate or tablet fixed to a wall to mark an event, person, etc.

* Memorial Plaque (medallion), issued to next-of-kin of dead British military personnel after World War I

* Pla ...

build-up under the prosthesis. Margins can be detected automatically which would normally have to be delineated by a technician visually. They can also be adjusted manually.

* The path of insertion axis can be determined automatically which dictates the direction the dental prosthesis

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the denta ...

must move to fit into the tooth/mouth.

* Measurements can be made between points on the digital model which can help inform the technician if any modifications to the tooth are needed to accommodate the dental prosthesis. The material must be thick enough to provide adequate strength but also not so thick as to cause the restored tooth to contact the opposing tooth before all other teeth in the arch – this would prop the patient’s mouth open and prevent them from being able to bite normally.

Materials used in CAD/CAM

CADCAM is a rapidly evolving field, hence the materials in use are always changing. Some of the current materials that can be manufactured using CADCAM software include metals, porcelain, lithium disilicate, zirconia and resin materials. CAD/CAM restorations are milled from solid blocks of ceramic or composite-resin. If pre-sintered ceramic ingots are used, subsequent sintering to reduce porosity is required and the CAD-CAM technology needs to account for any casting shrinkage during this process. Glass-based restorations can also be manufactured using CAD-CAM. Similar to ceramics, milling of glass ingots occurs and molten glass infiltration is used to reduceporosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure ...

. The advantage of materials manufactured by CADCAM is the consistency in quality of restoration when mass produced.

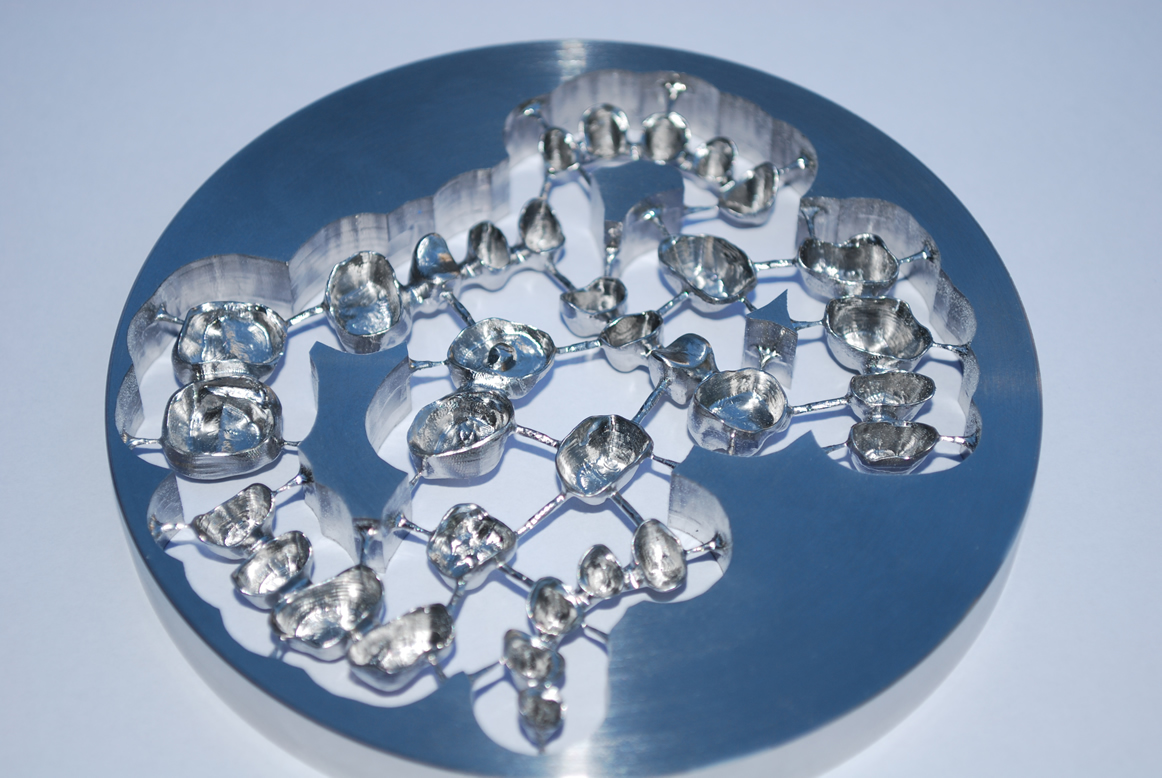

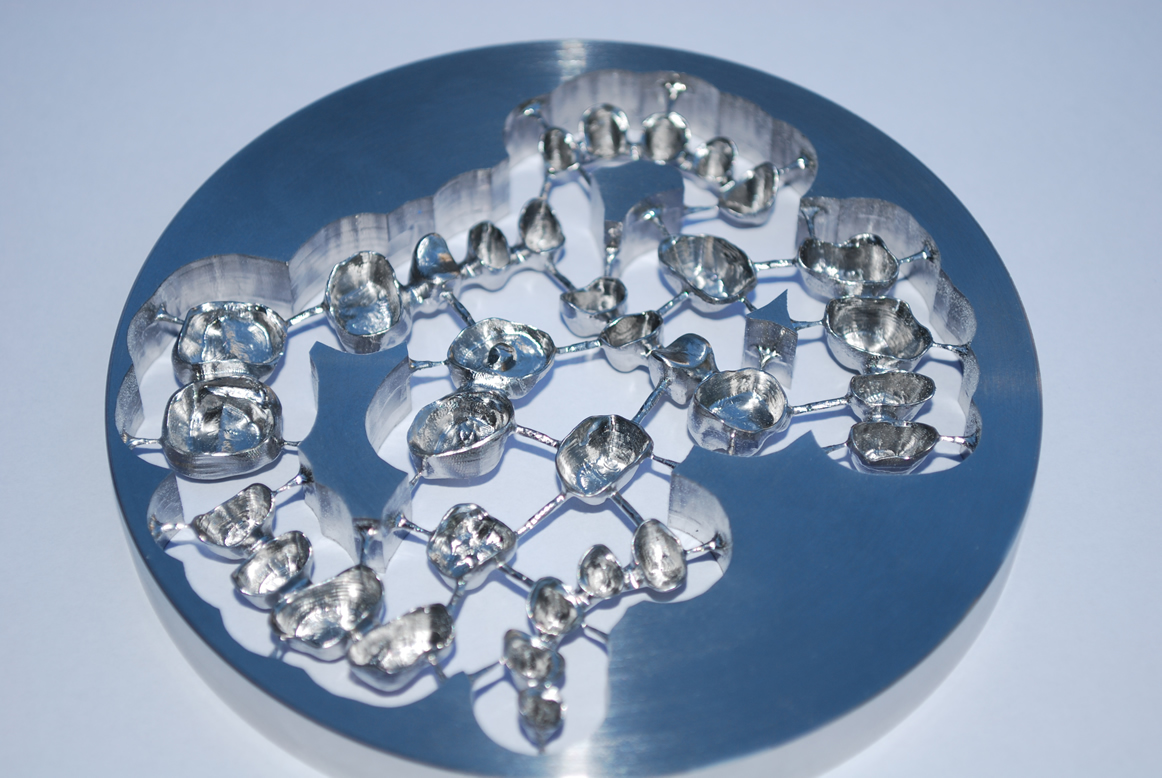

Metals

Metals such as CoCr and titanium can be manufactured using CADCAM software. Precious metals cannot be machined for a variety of reasons, including expense. Pre-sintered CoCr blocks are available, and requires sintering after to achieve the desiredmechanical properties

A materials property is an intensive property of a material, i.e., a physical property that does not depend on the amount of the material. These quantitative properties may be used as a metric by which the benefits of one material versus another ca ...

. This method replaces the more traditional lost-wax technique.

Ceramics

Feldspathic and leucite-reinforced ceramics

The microstructure of feldspathic and leucite reinforced ceramics is a glassy matrix with crystalline loads. It has lowflexural strength

Flexural strength, also known as modulus of rupture, or bend strength, or transverse rupture strength is a material property, defined as the stress in a material just before it yields in a flexure test. The transverse bending test is most freque ...

, very good optical properties and an advantageous bonding abilities. A major advantage is its good aesthetics, with a variety of shades available and high translucency. However, it is a fragile material and is susceptible to damage by occlusal forces.

Lithium disilicate, zirconium oxide and lithium silicate ceramics

Lithium disilicate, zirconium oxide and lithium silicate ceramics also have a biphasic structure with crystalline particles dispersed in a glass matrix. They have a high flexural strength, good optical properties and ability to bond. It produces highly aesthetic restorations in a variety of shades is useful as well as its high mechanical strength.Zirconia

Zirconia has a polycrystalline structure. It has a high flexural strength. However, both its optical properties and ability to bond are weak. Its main advantage is its mechanical strength. CAD-CAM processing means that polycrystalline zirconia can be utilised for copings and frameworks. Its superior mechanical properties means it can be used for long-span bridgework, cores can be produced in thinner layers and can be utilised in posterior fixed partial dentures. However, the aesthetics of zirconia restorations are not as good as other types of ceramic.Resin Materials

There are three resin materials available: resin composite, PMMA, and Nano-ceramics. PMMA is made of polymethylmethacrylate polymers with no filler. However, resin composite is composed of inorganic filler in a resin matrix. Similarly, nano-ceramic isnanoparticle

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 1 ...

s embedded in a resin matrix. All three materials have a weak flexural strength and disadvantageous optical properties. However, the ability to bond is very effective. An advantage of these materials is the ability to manufacture them quickly through fast milling, so are great to sued for direct composite repairs. However, the aesthetic quality of these materials limit their utility.

Advantages and drawbacks

CAD/CAM has improved the quality of prostheses in dentistry and standardised the production process. It has increased productivity and the opportunity to work with new materials with a high level of accuracy. Though CAD/CAM is a major technological advancement, it is important that the dentists’ technique is suited to CAD/CAM milling. This includes: correct tooth preparation with a continuous preparation margin (which is recognisable to the scanner e.g. in the form of a chamfer); avoiding the use of shoulderless preparations and parallel walls and the use of rounded incisor and occlusal edges to prevent the concentration of tension. Crowns and bridges require a precise fit on tooth abutments or stumps. Fit accuracy varies according to the CAD/CAD system utilized and from user to user. Some systems are designed to attain higher standards of accuracy than others and some users are more skilled than others. It is estimated that 20 new systems are expected to become available by 2020. Further research is needed to evaluate CAD/CAM technology compared to the other attachment systems (such as ball, magnetic and telescopic systems), as an option for attaching overdentures to implants.Advantages of CAD/CAM

The advantages CAD/CAM provides when compared with the traditional laboratory and chairside led techniques are that it 1) allows for use of materials otherwise unavailable in the laboratory; 2) provides cheaper alternatives when compared with conventional materials; 3) decreases labour cost and time for dental technicians and 4) standardises the quality of restorations. Ceramic materials in particular, can be highly time-consuming to work with. To make a ceramic dental prosthesis by hand, the technician has to meticulously build up porcelain powder and sinter it onto the surface of a coping. With CAD/CAM, labour times are significantly reduced, with CAD systems with some reviews reporting that only 5–6 minutes of technician input is required to produce a dental prosthesis. In this way, the cost of production is reduced because labour costs are lower. Furthermore, CAD/CAM systems mill prosthesis from blocks of material which are mass manufactured, again reducing costs for the dental offices and laboratories when compared with traditional techniques. These blocks are made so that any internal porosities have been removed which are difficult to eliminate during conventional fabrication. CAD/CAM has also found great merit with regards to reducing the shrinkage which occurs when ceramics are heated duringsintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

– a process required to give the ceramic restoration adequate strength so it can be used successfully within the mouth. It is difficult to account for this phenomenon in a dental laboratory using traditional techniques. CAM can reduce shrinkage by two different methods. The first is to produce a prosthesis just greater than the desired size. This means that on firing, the prosthesis will shrink to the original intended size. The second is by milling the prosthesis from a block that has already been fully sintered, which eliminates shrinkage but causes increased wear on cutting tools because the block is stronger than when partially sintered.

Benefits of Intraoral Scanning

The advent of intraoral scanners affords additional advantages when compared with the traditional physical workflow, particularly for dentists. In the traditional method, dental impressions must be taken, and the materials used to facilitate this are vulnerable to distortion over time which can decrease the accuracy of the eventualdental prosthesis

A dental prosthesis is an intraoral (inside the mouth) prosthesis used to restore (reconstruct) intraoral defects such as missing teeth, missing parts of teeth, and missing soft or hard structures of the jaw and palate. Prosthodontics is the denta ...

. These inaccuracies are compounded by subsequent steps such as the fabrication of study models based on the impressions. Intra-oral scanners rapidly digitise what they scan which removes the risk of distortion/damage to the date. Furthermore, dental impressions are often discomforting for patients, particularly those who have a strong gag reflex due to the bulk of material needed to capture a patient’s entire dentition. Intra-oral scanners reduce this element.

Intra-oral scanning saves considerable time in post processing when compared with conventional dental impressions. This is because the 3D model can be instantly emailed to a dental laboratory whereas with the conventional technique, the impression must be disinfected and physically transported to the laboratory which is a longer process.

Disadvantages of CAD/CAM

# Learning curve: With any new technology there is a steep learning curve. With time and experience operators will need to understand how to work the equipment and software used for CAD/CAM technology. Initially it can be difficult to adopt a new digital workflow when operators were comfortable with using their long-standing process in dentistry. This would also mean staff would need to be trained to feel comfortable using CAD/CAM systems. # High Cost: digital dentistry requires a huge financial investment, from buying and maintaining equipment to software updates it can add to the cost. However, in the long run the investment will pay off as it can save money on expenses such as laboratory fees and single use impression equipment. # Error in occlusion assessment & still require human input: Compared to the conventional technique of making complete dentures, CAD/CAM has few disadvantages. The systems does not accurately assess element of balanced occlusion. As the denture teeth are not set on the denture based with the assistance of an articulator, there is difficulty in achieving a balanced occlusion. Hence, there is still the human element, and the teeth will have to be clinically remounted to achieve balanced occlusion. # Environmental impact: resin particles are produced during the milling process which adds to environmental issue ofplastic pollution

Plastic pollution is the accumulation of plastic objects and particles (e.g. plastic bottles, bags and microbeads) in the Earth's environment that adversely affects humans, wildlife and their habitat. Plastics that act as pollutants are catego ...

.

Future Prospects

Digital dentistry is growing at an accelerating and it offers unprecedented and wonderful opportunities to improve dental care. The future is digital, with the world making many advancements with technology, CAD/CAM systems will keep evolving and improving as we develop a better understanding of the advantages and limitations of it.References

{{DEFAULTSORT:CAD CAM Dentistry Computer-aided design Computer-aided manufacturing Dentistry branches