bowden cable on:

[Wikipedia]

[Google]

[Amazon]

A Bowden cable ( )

is a type of flexible cable used to transmit

A Bowden cable ( )

is a type of flexible cable used to transmit

The potential of the Bowden cable and associated brake was not to be fully realised until the freewheel sprocket became a standard feature of bicycles, over the period 1899-1901, and increasing numbers of applications were found for it, such as gear change mechanisms. Importantly in 1903, Hendee developed the twist-grip throttle using a similar cable for his 'Indian' motorcycles. Its lightness and flexibility recommended it to further automotive use such as clutch and speedometer drive cables.

It is reported that "on 12th January 1900 E. M. Bowden granted a licence to ''The Raleigh Cycle Company of Nottingham''", whose directors were Frank Bowden and Edward Harlow. At this signing they became members of 'E. M. Bowden's Patent Syndicate Limited'. The syndicate included, among others, R. H. Lea & Graham I. Francis of Lea & Francis Ltd, and William Riley of the Riley Cycle Company. The Raleigh company were soon offering the Bowden Brake as an accessory, and were quick to incorporate the cable into handlebar mounted Sturmey-Archer (in which they had a major interest) gear changes. Undoubtedly this is why E. Bowden and F. Bowden are sometimes confused today.

Early Bowden cable, from the 1890s and first years of the twentieth century, is characterised by the outer tube being wound from round wire and being uncovered. Each length is usually fitted with a brass collar marked 'BOWDEN PATENT', (this legend is also stamped into the original brake's components). More modern outer tube is wound from square section wire. From c1902 the cable was usually covered in a waterproof fabric sheath; in the early post war period this was replaced by plastic.

The potential of the Bowden cable and associated brake was not to be fully realised until the freewheel sprocket became a standard feature of bicycles, over the period 1899-1901, and increasing numbers of applications were found for it, such as gear change mechanisms. Importantly in 1903, Hendee developed the twist-grip throttle using a similar cable for his 'Indian' motorcycles. Its lightness and flexibility recommended it to further automotive use such as clutch and speedometer drive cables.

It is reported that "on 12th January 1900 E. M. Bowden granted a licence to ''The Raleigh Cycle Company of Nottingham''", whose directors were Frank Bowden and Edward Harlow. At this signing they became members of 'E. M. Bowden's Patent Syndicate Limited'. The syndicate included, among others, R. H. Lea & Graham I. Francis of Lea & Francis Ltd, and William Riley of the Riley Cycle Company. The Raleigh company were soon offering the Bowden Brake as an accessory, and were quick to incorporate the cable into handlebar mounted Sturmey-Archer (in which they had a major interest) gear changes. Undoubtedly this is why E. Bowden and F. Bowden are sometimes confused today.

Early Bowden cable, from the 1890s and first years of the twentieth century, is characterised by the outer tube being wound from round wire and being uncovered. Each length is usually fitted with a brass collar marked 'BOWDEN PATENT', (this legend is also stamped into the original brake's components). More modern outer tube is wound from square section wire. From c1902 the cable was usually covered in a waterproof fabric sheath; in the early post war period this was replaced by plastic.

/ref> In this narrative a flexible cable brake for cycles was separately 'invented' by George Frederick Larkin, a skilled automobile and motorcycle engineer, who patented his design in 1902. He was subsequently recruited by, and worked for E.M. Bowden until 1917 as ''General Works Manager''.

A Bowden cable ( )

is a type of flexible cable used to transmit

A Bowden cable ( )

is a type of flexible cable used to transmit mechanical

Mechanical may refer to:

Machine

* Machine (mechanical), a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement

* Mechanical calculator, a device used to perform the basic operations ...

force

In physics, a force is an influence that can change the motion of an object. A force can cause an object with mass to change its velocity (e.g. moving from a state of rest), i.e., to accelerate. Force can also be described intuitively as a ...

or energy

In physics, energy (from Ancient Greek: ἐνέργεια, ''enérgeia'', “activity”) is the quantitative property that is transferred to a body or to a physical system, recognizable in the performance of work and in the form of ...

by the movement of an inner cable relative to a hollow outer cable housing. The housing is generally of composite construction, consisting of an inner lining, a longitudinally incompressible layer such as a helical winding or a sheaf of steel wire, and a protective outer covering.

The linear movement of the inner cable is most often used to transmit a pulling force, although push/pull cables have gained popularity in recent years e.g. as gear shift cables. Many light aircraft use a push/pull Bowden cable for the throttle control, and here it is normal for the inner element to be a solid wire, rather than a multi-strand cable. Usually, provision is made for adjusting the cable tension using an inline hollow bolt (often called a "barrel adjuster"), which lengthens or shortens the cable housing relative to a fixed anchor point. Lengthening the housing (turning the barrel adjuster out) tightens the cable; shortening the housing (turning the barrel adjuster in) loosens the cable.

History

The origin and invention of the Bowden cable is open to some dispute, confusion and myth. The invention of the Bowden cable has been popularly attributed to Sir Frank Bowden, founder and owner of the Raleigh Bicycle Company who, circa 1902, was reputed to have started replacing the rigid rods used for brakes with a flexible wound cable but no evidence for this exists. The ''Bowden mechanism'' was invented by Irishman Ernest Monnington Bowden (1860 to April 3, 1904) of 35 Bedford Place, London, W.C. The first patent was granted in 1896 (English Patent 25,325 and U.S. Pat. No. 609,570), and the invention was reported in the Automotor Journal of 1897 where Bowden's address was given as 9 Fopstone Rd, Earls Court. The two Bowdens are not known to be closely related. The principal element of this was a flexible tube (made from hard wound wire and fixed at each end) containing a length of fine wire rope that could slide within the tube, directly transmitting pulling, pushing or turning movements on the wire rope from one end to the other without the need of pulleys or flexible joints. The cable was particularly intended for use in conjunction with bicycle brakes. The Bowden Brake was launched amidst a flurry of enthusiasm in the cycle press in 1896. It consisted of a stirrup, pulled up by the cable from a handlebar mounted lever, with rubber pads acting against the rear wheel rim. At this date bicycles were fixed-wheel (no freewheel), additional braking being offered by a 'plunger' brake pressing on the front tyre. The Bowden offered extra braking power still, and was novel enough to appeal to riders who scorned the plunger arrangement, which was heavy and potentially damaging to the (expensive) pneumatic tyre. The problem for Bowden was his failure to develop effective distribution networks and the brake was often incorrectly, or inappropriately fitted, resulting in a good number of complaints being aired in the press. Its most effective application was on those machines fitted with Westwood pattern steel rims which offered flat bearing surfaces for the brake pads. The potential of the Bowden cable and associated brake was not to be fully realised until the freewheel sprocket became a standard feature of bicycles, over the period 1899-1901, and increasing numbers of applications were found for it, such as gear change mechanisms. Importantly in 1903, Hendee developed the twist-grip throttle using a similar cable for his 'Indian' motorcycles. Its lightness and flexibility recommended it to further automotive use such as clutch and speedometer drive cables.

It is reported that "on 12th January 1900 E. M. Bowden granted a licence to ''The Raleigh Cycle Company of Nottingham''", whose directors were Frank Bowden and Edward Harlow. At this signing they became members of 'E. M. Bowden's Patent Syndicate Limited'. The syndicate included, among others, R. H. Lea & Graham I. Francis of Lea & Francis Ltd, and William Riley of the Riley Cycle Company. The Raleigh company were soon offering the Bowden Brake as an accessory, and were quick to incorporate the cable into handlebar mounted Sturmey-Archer (in which they had a major interest) gear changes. Undoubtedly this is why E. Bowden and F. Bowden are sometimes confused today.

Early Bowden cable, from the 1890s and first years of the twentieth century, is characterised by the outer tube being wound from round wire and being uncovered. Each length is usually fitted with a brass collar marked 'BOWDEN PATENT', (this legend is also stamped into the original brake's components). More modern outer tube is wound from square section wire. From c1902 the cable was usually covered in a waterproof fabric sheath; in the early post war period this was replaced by plastic.

The potential of the Bowden cable and associated brake was not to be fully realised until the freewheel sprocket became a standard feature of bicycles, over the period 1899-1901, and increasing numbers of applications were found for it, such as gear change mechanisms. Importantly in 1903, Hendee developed the twist-grip throttle using a similar cable for his 'Indian' motorcycles. Its lightness and flexibility recommended it to further automotive use such as clutch and speedometer drive cables.

It is reported that "on 12th January 1900 E. M. Bowden granted a licence to ''The Raleigh Cycle Company of Nottingham''", whose directors were Frank Bowden and Edward Harlow. At this signing they became members of 'E. M. Bowden's Patent Syndicate Limited'. The syndicate included, among others, R. H. Lea & Graham I. Francis of Lea & Francis Ltd, and William Riley of the Riley Cycle Company. The Raleigh company were soon offering the Bowden Brake as an accessory, and were quick to incorporate the cable into handlebar mounted Sturmey-Archer (in which they had a major interest) gear changes. Undoubtedly this is why E. Bowden and F. Bowden are sometimes confused today.

Early Bowden cable, from the 1890s and first years of the twentieth century, is characterised by the outer tube being wound from round wire and being uncovered. Each length is usually fitted with a brass collar marked 'BOWDEN PATENT', (this legend is also stamped into the original brake's components). More modern outer tube is wound from square section wire. From c1902 the cable was usually covered in a waterproof fabric sheath; in the early post war period this was replaced by plastic.

Possible contribution by Larkin

An unpublished typescript exists in the archives of the National Motor Museum, written by the son of one of Bowden's employees that attempts to claim the invention of the cable for his father to the point of suggesting that it was never applied to bicycles before 1902. Although this is easily disproved by reference to 'Cycling' or the other UK cycle press through 1896–97, it serves to remind one of the attempts made to rewrite cycle history through priority claims.British National Archives

, type = Non-ministerial department

, seal =

, nativename =

, logo = Logo_of_The_National_Archives_of_the_United_Kingdom.svg

, logo_width = 150px

, logo_caption =

, formed =

, preceding1 =

, dissolved =

, superseding =

, juris ...

National Archives, National Motor Museum, George Larkin Collection/ref> In this narrative a flexible cable brake for cycles was separately 'invented' by George Frederick Larkin, a skilled automobile and motorcycle engineer, who patented his design in 1902. He was subsequently recruited by, and worked for E.M. Bowden until 1917 as ''General Works Manager''.

"George Larkin is known for his invention of the flexible cable brake for cycles, which was patented in 1902. The original patent for a similar invention known as the 'Bowden mechanism' was granted to Ernest Monnington Bowden in 1896. The following year E.M. Bowden's Patents Syndicate Ltd. was formed to market the device but initially the project was a failure because all the company could offer was a flimsy mechanism capable of transmitting comparatively enormous power. The Bowden Mechanism was not developed in connection with a cycle brake as there is no record of the cable having been associated with the cycle industry until 1902, when George Larkin's invention was patented."

"During Larkin's employment with Bassett Motor Syndicate his duties included the assembly of motor cars and motor cycles, and a major difficulty was the assembly of the braking systems which at that time comprised steel rods, not easily adaptable to the contour of the chassis. He designed a flexible cable brake and approached S.J. Withers, Patent Agent, to have the design patented. Withers noticed the similarity of Larkin's idea to the Bowden Mechanism and introduced him to the Bowden Syndicate, who agreed to manufacture and market the invention with the proviso that it should be patented jointly in the names of the inventor and themselves. Within a few months, Larkin, then aged 23, was engaged as Motor Department Manager with E.M. Bowden's Patents Syndicate, and he was appointed General Works Manager on 1 May 1904."

Parts and variations

Housing

The original, standard Bowden cable housing consists of a close-wound helix of round or square steel wire. This makes a flexible housing but causes the length to change as the housing flexes. Because on the inside of the bend the turns of a close-wound helix can't get any closer together, the bending causes the turns to separate on the outside of the bend, and so at the centerline of the housing, there must also be an increase of length with increasing bend. In order to support indexed shifting,Shimano

, originally and later , is a Japanese multinational manufacturing company for cycling components, fishing tackles and rowing equipment, who also produced golf supplies until 2005 and snowboarding gear until 2008. Named after founder Shozabu ...

developed a type of housing that does not change length as it is flexed. This housing has several wire strands running in a multiple helix, with a pitch short enough such that bends in the cable are shared by all strands, but long enough so that the housing's flexibility comes by bending the individual strands rather than by twisting them. A consequence of a long winding pitch in a support helix is that it approaches the case of parallel strands where the wires are bound only by the plastic jacket. Housings with a long helix cannot withstand the high compression that is associated with high cable tensions, and on overload tend to fail by the buckling

In structural engineering, buckling is the sudden change in shape ( deformation) of a structural component under load, such as the bowing of a column under compression or the wrinkling of a plate under shear. If a structure is subjected to a ...

of the housing strands. For this reason, helical support for ''brake cables'' is ''close wound'', while housings with a longer helix are used for less critical applications. Longitudinally arranged support wires are used in applications such as bicycle ''gear-shifting''.

A third type of housing consists of short hollow rigid aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

or carbon fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

cylinders slid over a flexible liner. Claimed benefits over steel wire housing include less weight, tighter curves, and less compression under load.

Inner wire

Innerwire rope

Steel wire rope (right hand lang lay)

Wire rope is several strands of metal wire twisted into a helix forming a composite

'' rope'', in a pattern known as ''laid rope''. Larger diameter wire rope consists of multiple strands of such laid rope in ...

s for push applications have an additional winding that runs in the opposite direction to the wind of the actual inner wire. The wind may be like that of a spring or a wind with a flat strip; these are called spring wrap and spiral wrap respectively.

Some applications such as lawn mower

A lawn mower (also known as a mower, grass cutter or lawnmower) is a device utilizing one or more revolving blades (or a reel) to cut a grass surface to an even height. The height of the cut grass may be fixed by the design of the mower, but g ...

throttles, automobile manual chokes, and some bicycle shifting systems require significant pushing ability and so use a cable with a solid inner wire. These cables are usually less flexible than ones with stranded inner wires.

Ends

One end of the inner cable may have a small shaped piece of metal, known (from the pear-shaped soldered terminations used in some cases) as a nipple (as can be seen in the BMX rear brake detangler picture) that fits into a shifter or brake lever mechanism. The other end is often clamped (as can be seen in the rearderailleur

Shimano 600 front derailleur (1980)

A derailleur is a variable-ratio bicycle gearing system consisting of a chain, multiple sprockets of different sizes, and a mechanism to move the chain from one sprocket to another.

Modern front and rear d ...

picture) to the part of the brake or shifter that needs to be moved, or as is most common with motorcycle control cables, fitted with another nipple.

Traditionally, in bicycles, shifter cables are anchored on the shifter with a small cylindrical nipple, concentric with the cable. Bicycle brake nipples however, vary between mountain bikes (MTB), with straight handlebars, and road bikes, with drop-handlebars. MTB bikes use a barrel-shaped (cylindrical) nipple to anchor the brake cable at the brake lever, while road bikes have a pear-shaped nipple. Some replacement brake cables for bicycles come with both styles, one on each end. The unneeded end is cut off and discarded upon installation.

In bicycle applications, for both brakes and gear-shifting, the outer dimension of the cap or ferrule that terminates a housing, is selected to make a loose fit within the barrel-adjuster's end. In this way the barrel will slip on the ferrule as it is turned during adjustments. If the ferrule were to be jammed into the barrel end, then the cable would twist during fruitless attempts at adjustment.

Nipples are also available separately from the cable, for purposes of repair or custom cable construction. They are fitted to the cable by soldering

Soldering (; ) is a process in which two or more items are joined by melting and putting a filler metal ( solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not inv ...

. Where free rotation of nipples, relative to the cable axis is required, the cable end may be finished with a brass ferrule or "trumpet" soldered to the cable. The barrel nipple will be a sliding fit over the brass ferrule, and can thus rotate, to ensure alignment of the nipples at each end of the cable, and avoidance of twisting of the inner cable. Applying heat to the inner cable for soldering may weaken the steel, and although soft soldering is less strong than silver solder, a lower temperature is required to form the joint, and there is less likelihood of the inner cable being damaged as a result. Silver soldering may require additional heat treatment of the wire to preserve the temper of it in order to prevent it from becoming too soft or too brittle

Nipples that clamp to the cable by means of a screw also are available for emergency repair purposes, or where removal is required for maintenance.

A small ferrule

A ferrule (a corruption of Latin ' "small bracelet", under the influence of ' "iron") is any of a number of types of objects, generally used for fastening, joining, sealing, or reinforcement. They are often narrow circular rings made from me ...

, also called a 'crimp', (seen in the rear derailleur picture) may be crimped on to prevent cable ends from fraying.

Other methods to prevent fraying include soft or silver soldering the wire ends, or ideally by flash cutting the wires.

If the inner wire is solid, as in automotive and lawnmower throttle and choke applications, it may simply have a bend at one or both ends to engage what ever it pushes or pulls.

Donuts

Small rubber tori, called donuts, can be threaded onto a bare run of the inner cable to prevent it from striking the bicycle frame causing rattles or abrasion.Common practice

The indexed shifting of a bicycle derailleur needs to be exact. A typical 7-speed shifter changes the cable length by either 2.9 mm (Shimano 2:1) or 4.5 mm (SRAM 1:1) for each shift, and any length errors accumulate with the number of shifts. To this end, the housing needs to behave as if it were a solid tube, so it, and its end-pieces have to be compressionless. Currently, the most commonly used compressionless housing for gear shifting has longitudinally spaced steel wires. The flat-cut ends of such housing are tight-terminated with end caps or ferrules, and the ends caps are sized to fit either into a fixture on the frame, or as a loose fitting in the end of a barrel adjuster. Housings for bicycle brakes need not be quite so compressionless, but need to be stronger, and items currently sold for this purpose use a close-wound spiral support wire. One end of a brake housing is tight-terminated in an end cap or ferrule that makes a loose fit within a barrel adjuster, and the other in any of a variety of fittings that includes end caps, or parts to effect a smooth change of direction. In any case, at the point where the cable emerges for attachment to the brake arms, is fitted a nipple. In view of the wide array of cable constructions on offer, confusion as to the best housing can easily result. In general, a housing sold for one purpose should not be used for any other, and in any case the advice of the manufacturer should be followed. In particular, longitudinally reinforced housings should not be used for bicycle brakes, since they are weaker than the spirally wound housings. Housings for bicycles are made in two main diameters; most often 4 mm diameter is used for gear-shifting and 5 mm for brakes. Both shifting and brake housings are manufactured in both sizes. However, some care is needed in ''changing'' cables, since, for example, the 4 mm barrel adjuster end of an existing shifter is probably made only for that housing size. Although the individual parts for cable assembly can be acquired, ready-made cables for both brakes and shifting are available. These usually consist of an inner wire within a length of housing, and depending on their purpose, with one or more end caps fitted. However, because of the wide range of fittings in use, it is probable that these universal cables' caps, although suiting many situations, will not suit every purpose, as their name wrongly implies. The shortening of housings requires the use of a special hand tool, designed to make a square cut without closing the cable entry. The same tool is used to cut the internal steel cable. To avoid unraveling of the cable's wires during installation, manufacturers weld or crimp the ends. Housings for cables have habitually been made only in black, though some colored housings can also be found.Maintenance

Bowden cables can cease to function smoothly, particularly if water or contaminants get into the housing. Modern lined and stainless steel cables are less prone to these problems; unlined housings should be lubricated with a light machine oil. In cold climates Bowden cable mechanisms are prone to malfunction due to water freezing. Cables also wear through use over a long time, and can be damaged through kinking or raveling. A common failure occurs on bicycles at the point where the housing enters a barrel adjuster; loose housing ends tend to fray the housing, making adjustments uncertain. Fraying due to fatigue is most likely if the cable passes over a pulley, which on bicycles is often below the recommended diameter, or where the cable is bent repeatedly where it attaches to the brake lever or caliper. A cable passing around a sharp bend tend to furrow the inner cable sleeve, leading to contact with the outer housing and rub fraying. A frayed cable can suddenly break when force is applied strongly, e.g. during emergency braking. The specifications for cables and housings rarely give any details other than dimensions and the purpose of the products. The specific resistance to compression or bending is never quoted, so there is much rhetorical evidence and comment as to the performance and durability of products, but little available science for the consumer's use. A particularly severe quality test for housings is at or near the hinge of afolding bicycle

A folding bicycle is a bicycle designed to fold into a compact form, facilitating transport and storage. When folded, the bikes can be more easily carried into buildings, on public transportation (facilitating mixed-mode commuting and bicycl ...

where a sharp bend is made repeatedly. The radius of curvature of cables on a folded bicycle can be as low as 1.5 inches, (4 cm); therefore it is advisable to shift to the gear with the lowest cable pressure before folding, to minimize any adverse effects on housings or derailleurs. This gear is usually the one with the ''highest index number'' on the gear shifter.

There is some controversy surrounding the existence of the phenomenon known as "cable stretch". Newly installed cables can seem to elongate, requiring readjustment. While it is generally agreed that inner wires actually stretch very little - if at all - housings and linings may compress slightly, and all parts may generally "settle in". Lightweight assemblies such as those used on bicycles are more susceptible to this phenomenon.

Uses

* Sustain pedal linkage onWurlitzer electric piano

The Wurlitzer electronic piano is an electric piano manufactured and marketed by Wurlitzer from the mid-1950s to mid-1980s. Sound is generated by striking a metal reed with a hammer, which induces an electric current in a pickup. It is concept ...

s

* Bicycle brakes and gear shift

A gear stick (rarely spelled ''gearstick''), gear lever (both UK English), gearshift or shifter (both U.S. English), more formally known as a transmission lever, is a metal lever attached to the transmission of an automobile. The term ''gear s ...

cables

* Photographic

Photography is the art, application, and practice of creating durable images by recording light, either electronically by means of an image sensor, or chemically by means of a light-sensitive material such as photographic film. It is employed ...

shutter release cables

* Automotive clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). ...

, throttle

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction.

An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle' ...

/cruise control

Cruise control (also known as speed control, cruise command, autocruise, or tempomat) is a system that automatically controls the speed of a motor vehicle. The system is a servomechanism that takes over the throttle of the car to maintain a ...

, emergency brake, and various latch

A latch or catch (called sneck in Northern England and Scotland) is a type of mechanical fastener that joins two (or more) objects or surfaces while allowing for their regular separation. A latch typically engages another piece of hardware on t ...

release cables

* Aircraft engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years ma ...

controls including throttle or power control, propeller pitch or RPM, fuel mixture, carburetor heat, and cowl flaps

* Motorcycle

A motorcycle (motorbike, bike, or trike (if three-wheeled)) is a two or three-wheeled motor vehicle Steering, steered by a Motorcycle handlebar, handlebar. Motorcycle design varies greatly to suit a range of different purposes: Long-distance ...

throttle, clutch and (now rarely) brake cables

* Control surfaces on small aircraft

An aircraft is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or by using the Lift (force), dynamic lift of an airfoil, or in ...

Jabiru J160 Constructors Manual

* Remote hi-hats in drum kit

A drum kit (also called a drum set, trap set, or simply drums) is a collection of drums, cymbals, and other Percussion instrument, auxiliary percussion instruments set up to be played by one person. The player (drummer) typically holds a pair o ...

s

* Operate terminal device hook

A hook is a tool consisting of a length of material, typically metal, that contains a portion that is curved or indented, such that it can be used to grab onto, connect, or otherwise attach itself onto another object. In a number of uses, one e ...

on prosthetic arms

* Lawn mower

A lawn mower (also known as a mower, grass cutter or lawnmower) is a device utilizing one or more revolving blades (or a reel) to cut a grass surface to an even height. The height of the cut grass may be fixed by the design of the mower, but g ...

throttle and dead man's switch

* Interlocking in electrical switchgear

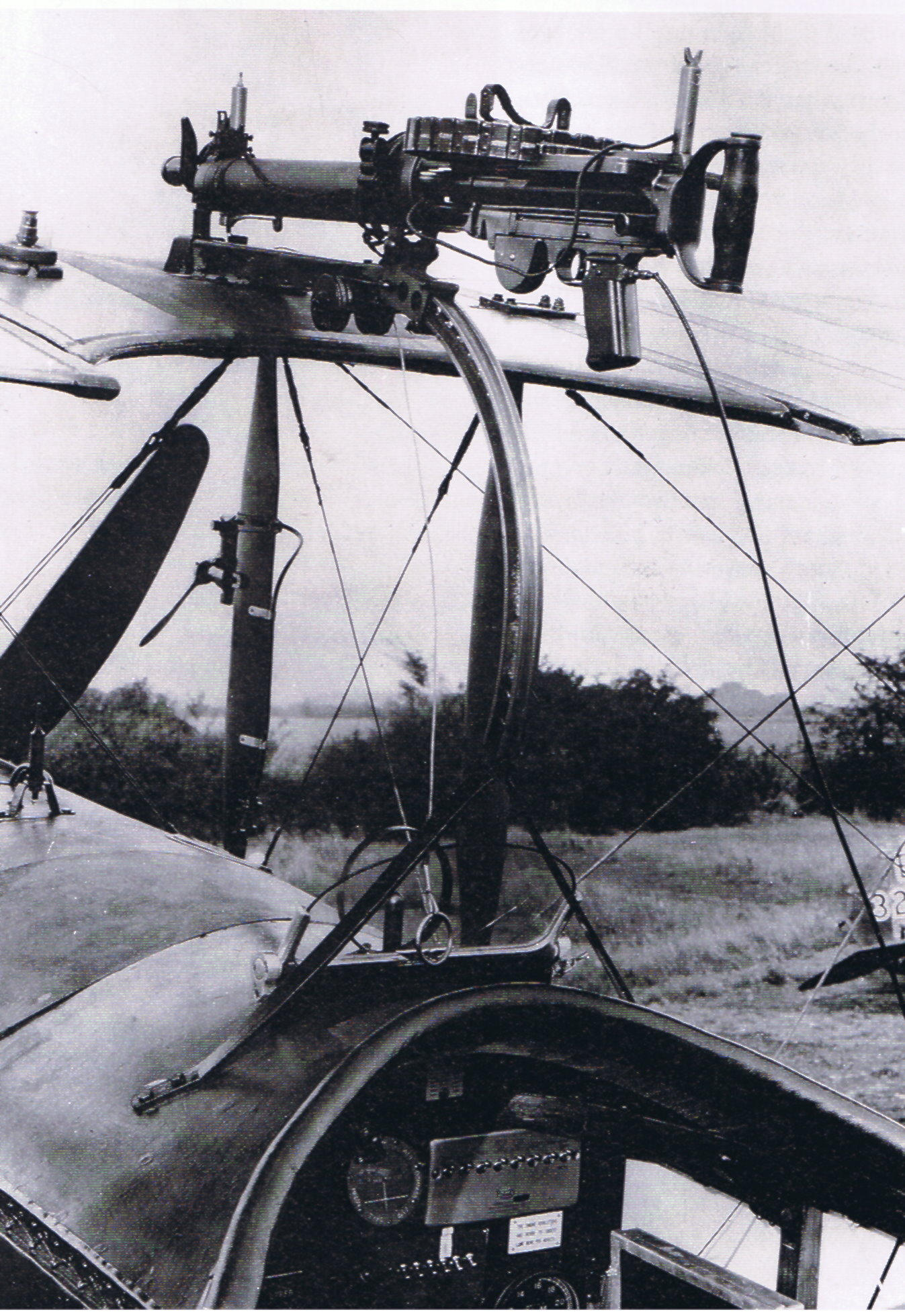

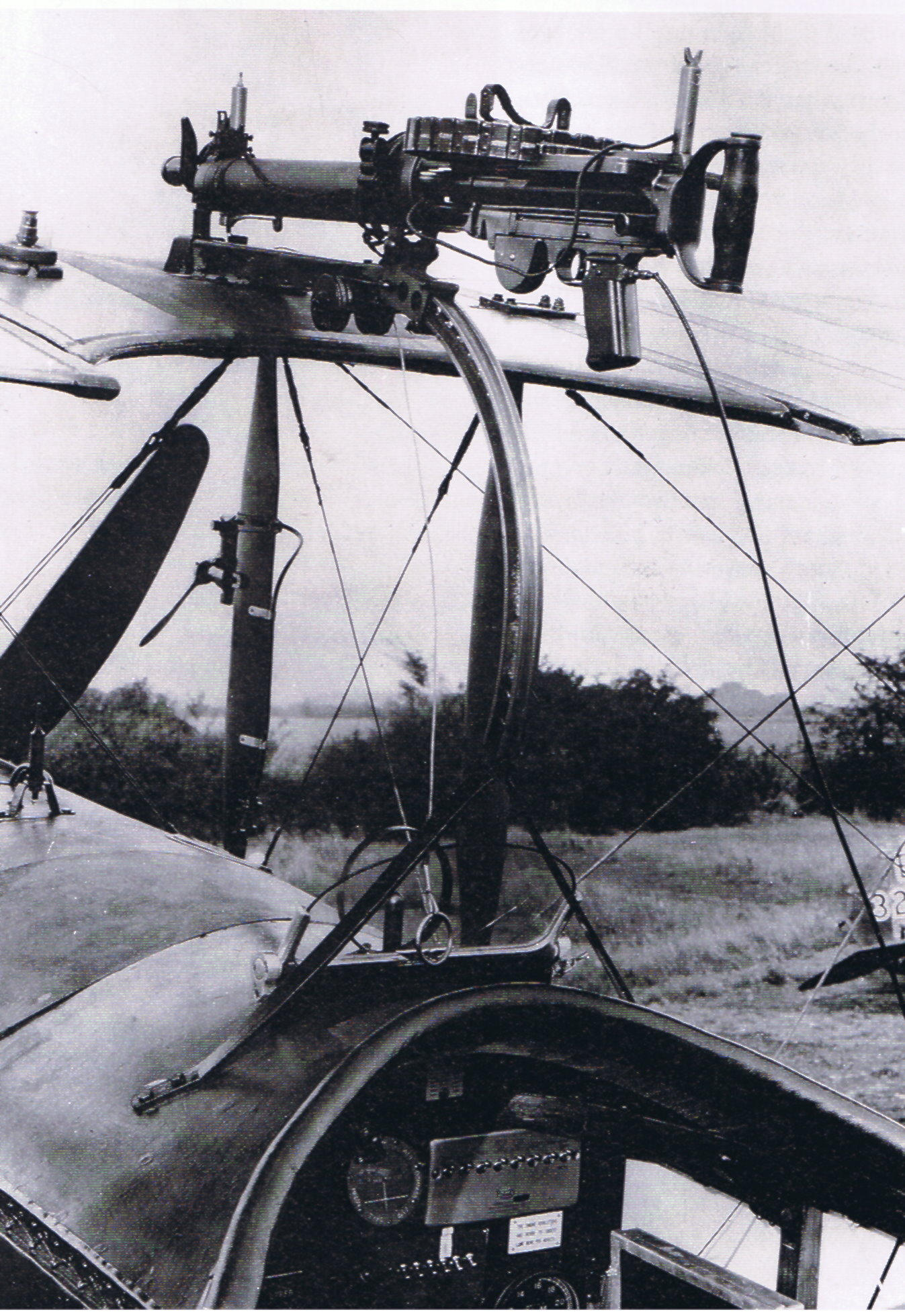

* Trigger activation for remotely located machine guns on French 1930s era Char B1 bis tanks, and for the DISA tripod used with the Madsen machine gun.

* Many 3-D printers of the type that extrude plastic filament use a "Bowden extruder

A 3D printer extruder is a 3D printing filament, filament feeding mechanism used in many fused filament fabrication (FFF) 3D printers. There are several types of 3D printer extruders. A Bowden cable, Bowden extruder is a type of extruder that pus ...

" to feed the filament through a tube, typically PTFE ('Teflon

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chemo ...

') to minimize friction, to the ' hot-end' where it is melted and deposited through a nozzle. This has the advantage of shifting the mass of the extruder's mechanism and stepper motor off of the moving hot-end to a fixed mount on the printer's frame, allowing greater printing speed and accuracy.

* Flexible drive shafts for ' Dremel'-type rotary multi-tools, die grinder

Die grinders and rotary tools are handheld power tools used for grinding, sanding, honing, polishing, or machining material (typically metal, but also plastic or wood). All such tools are conceptually similar, with no bright dividing line be ...

attachments for bench grinders, and the like

References

{{DEFAULTSORT:Bowden Cable Cables English inventions Bicycle parts 1902 introductions