Bootmaker Clicker on:

[Wikipedia]

[Google]

[Amazon]

A boot and shoe clicker is the person who cuts the uppers for  During the late 1960s synthetic leathers called ''pormerics'' were first introduced, and together with fabrics these also had lines of stretch and tension, being based on a traditional woven base having threads of

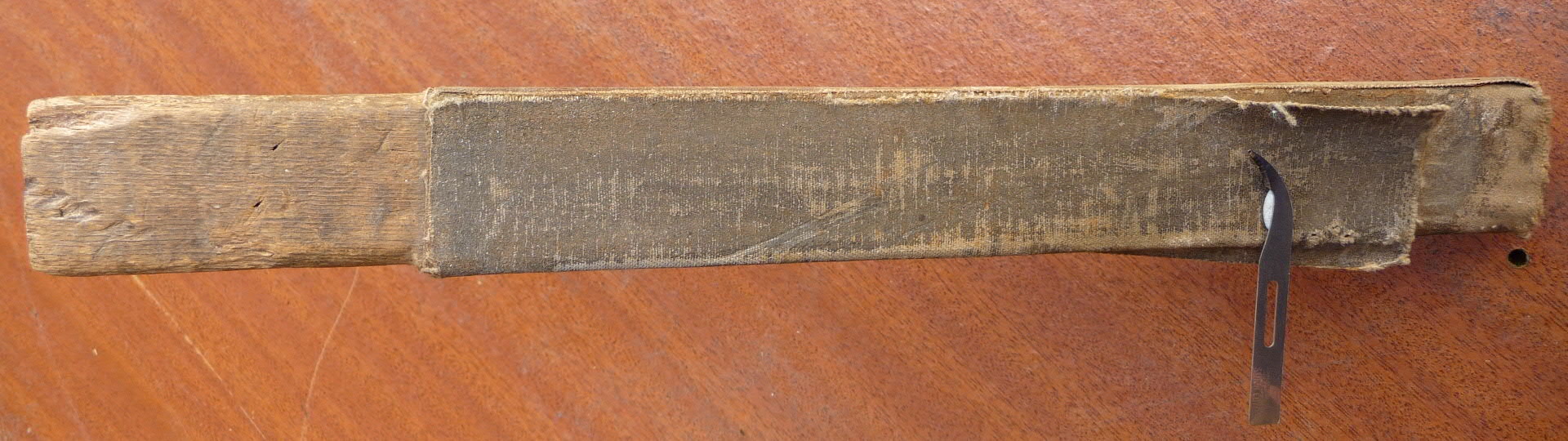

During the late 1960s synthetic leathers called ''pormerics'' were first introduced, and together with fabrics these also had lines of stretch and tension, being based on a traditional woven base having threads of  The clicker's knife regularly needed sharpening, which was done with an implement called a ''rap stick''.

To use a rap stick, a right-handed operator would hold it in the left hand, resting the stick on the workbench for support, stroking the blade rapidly but gently back and forth on the abrasive surface to maintain a sharp edge whilst hand-cutting, in a similar fashion to a butcher's knife and

The clicker's knife regularly needed sharpening, which was done with an implement called a ''rap stick''.

To use a rap stick, a right-handed operator would hold it in the left hand, resting the stick on the workbench for support, stroking the blade rapidly but gently back and forth on the abrasive surface to maintain a sharp edge whilst hand-cutting, in a similar fashion to a butcher's knife and

Overview of Bottom Stock

Rushden Research Group. Retrieved 2014-09-24

File:Leather cutter's drag knife.JPG, Leather cutter's drag knife, for heavy leathers

File:Vintage Texon 480 insole board offcut.JPG, Vintage Texon 480 insole board offcut showing direction of cut-outs where shoe insole patterns have been placed

File:Vintage Texon 480 insole board marked Cut Thus.JPG, Close-up of Texon 480 insole board with direction of cut marked as ''Cut Thus'' by manufacturer showing direction where shoe insole patterns should be placed. The board is formulated to have different properties along its length compared to across, to allow for shoe-flex and manufacturing processes

The late Baden Wilson demonstrating hand-clicking, using a hand-knife around a board 3/4 vamp pattern

Retrieved 2014-05-05

Hand-forming a press-knife, using pre-sharpened strip steel from a bulk coil

Retrieved 2014-05-05

Positioning the press-knife/pattern on leather placed on the nylon cutting-board of an hydraulic press prior to swivelling the press-head and cutting via a downstroke

Retrieved 2014-05-05

Shoemaking

boot

A boot is a type of footwear. Most boots mainly cover the foot and the ankle, while some also cover some part of the lower calf. Some boots extend up the leg, sometimes as far as the knee or even the hip. Most boots have a heel that is cle ...

s or shoe

A shoe is an item of footwear intended to protect and comfort the human foot. They are often worn with a sock. Shoes are also used as an item of decoration and fashion. The design of shoes has varied enormously through time and from culture t ...

s from a skin of leather

Leather is a strong, flexible and durable material obtained from the tanning, or chemical treatment, of animal skins and hides to prevent decay. The most common leathers come from cattle, sheep, goats, equine animals, buffalo, pigs and hogs, ...

or piece of man-made material (usually from a bulk roll). This includes all components of the upper, including linings, facings, stiffeners, reinforcements for eyelets and zip-protectors.

The job was historically named prior to mechanisation, due to the sound of the operator's hand-knife blade rattling against the brass edge-binding (including the joints in the binding) used to protect the board patterns which were overlaid on to the skin.

In larger factories there would be many hand-clickers in close proximity to one another, hence there would be many clicks per second, so the informal description became known as ''clicking'' by ''clickers''.

It is a skilled trade because it is the clicker's responsibility to maximise the number of uppers which can be cut from skins of leather, avoiding any thin and damaged areas, and incorporating the (unseen) 'lines' of stretch and resistance which naturally occur in leather according to the style and construction of the particular shoe. Another major criterion is the need to ''colour-shade'' the respective parts of the shoe uppers which are cut as a pair, not only matching the colour variations but also considering the surface finish and grain texture.

warp

Warp, warped or warping may refer to:

Arts and entertainment Books and comics

* WaRP Graphics, an alternative comics publisher

* ''Warp'' (First Comics), comic book series published by First Comics based on the play ''Warp!''

* Warp (comics), a ...

and weft

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft (sometimes woof) is draw ...

.

Following the introduction of electrical/mechanised presses, the sounds changed entirely to a heavy thump and/or crack, with the board pattern with hand-knife being replaced by a 'knife' similar to a pastry cutter, although the operator still needed to learn hand-clicking as part of the training.

Hand-clicking skills are still needed in low-volume production of bespoke, hand-made shoes or as sales-samples for factory production, although these would not warrant the expense of brass-binding used to protect the edges of the pattern from being pared away.

sharpening steel

A honing steel, sometimes referred to as sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They a ...

. The knife blade shown is a lighter medical item but approximates the shape of a clicker's knife blade, fitting into a comfortable wooden handle with screw-activated jaws. The main surface is emery cloth

upright=1.35, Sheets of sandpaper with different grit sizes (40 (coarse), 80, 150, 240, 600 (fine)).

Sandpaper and glasspaper are names used for a type of coated abrasive that consists of sheets of paper or cloth with abrasive material glued to ...

wrapped over the edge to form a round section where the curved blade can nestle and be sharpened; the top edge is sharper and square in cross-section, with a fine-grain aluminium oxide abrasive strip used for tip-sharpening. On the reverse side is a heavy-leather smooth strop, to address any metal burrs left by the abrasive process.

Bottom stock materials

Similar processes are used in preparing materials for the sole and heel of shoes, known as ''bottom stock'', although the materials, whether natural leathers, rubbers or synthetics, are heavier for durability. The clicker would also cut these materials in a small manufacturing facility, whereas larger-scale production would have dedicated operators.Rushden Research Group. Retrieved 2014-09-24

References

{{Reflist, 33emExternal links

The late Baden Wilson demonstrating hand-clicking, using a hand-knife around a board 3/4 vamp pattern

Retrieved 2014-05-05

Hand-forming a press-knife, using pre-sharpened strip steel from a bulk coil

Retrieved 2014-05-05

Positioning the press-knife/pattern on leather placed on the nylon cutting-board of an hydraulic press prior to swivelling the press-head and cutting via a downstroke

Retrieved 2014-05-05

Shoemaking