boiler feedwater pump on:

[Wikipedia]

[Google]

[Amazon]

A boiler feedwater pump is a specific type of pump used to pump

Steam locomotives and the steam engines used on ships and stationary applications such as

Steam locomotives and the steam engines used on ships and stationary applications such as

feedwater

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the ma ...

into a steam boiler. The water may be freshly supplied or returning condensate

Condensate may refer to:

* The liquid phase produced by the condensation of steam or any other gas

* The product of a chemical condensation reaction, other than water

* Natural-gas condensate, in the natural gas industry

* ''Condensate'' (album) ...

produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic ...

type or positive displacement type.

Construction and operation

Feedwater pumps range in size up to many kilowatts and theelectric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate for ...

is usually separated from the pump body by some form of mechanical coupling. Large industrial condensate pump A condensate pump is a specific type of pump used to pump the condensate (water) produced in an HVAC (heating or cooling), refrigeration, condensing boiler furnace, or steam system.

Applications

Condensate pumps may be used to pump the condensate ...

s may also serve as the feedwater pump. In either case, to force the water into the boiler, the pump must generate sufficient pressure to overcome the steam pressure developed by the boiler. This is usually accomplished through the use of a centrifugal pump.

Another common form of feedwater pump runs constantly and is provided with a minimum flow device to stop overpressuring the pump on low flows. The minimum flow usually returns to the tank or deaerator.

Failure of mechanical seal

Mechanical seals of boiler feedwater pumps often show signs of electrical corrosion. The relative movement between the sliding ring and the stationary ring provokes static charging which is not diverted due to the very low conductivity of the boiler water (below one micro-Siemens per cm �S/cm. Within short periods of operation – in some cases, only a few hundred operational hours – pieces having the size of fingertips break off from the sliding and/or the stationary ring and cause rapid increases in leakage current. Diamond-coated ( DLC) mechanical seals avoid this problem and extend durability remarkably.Steam-powered pumps

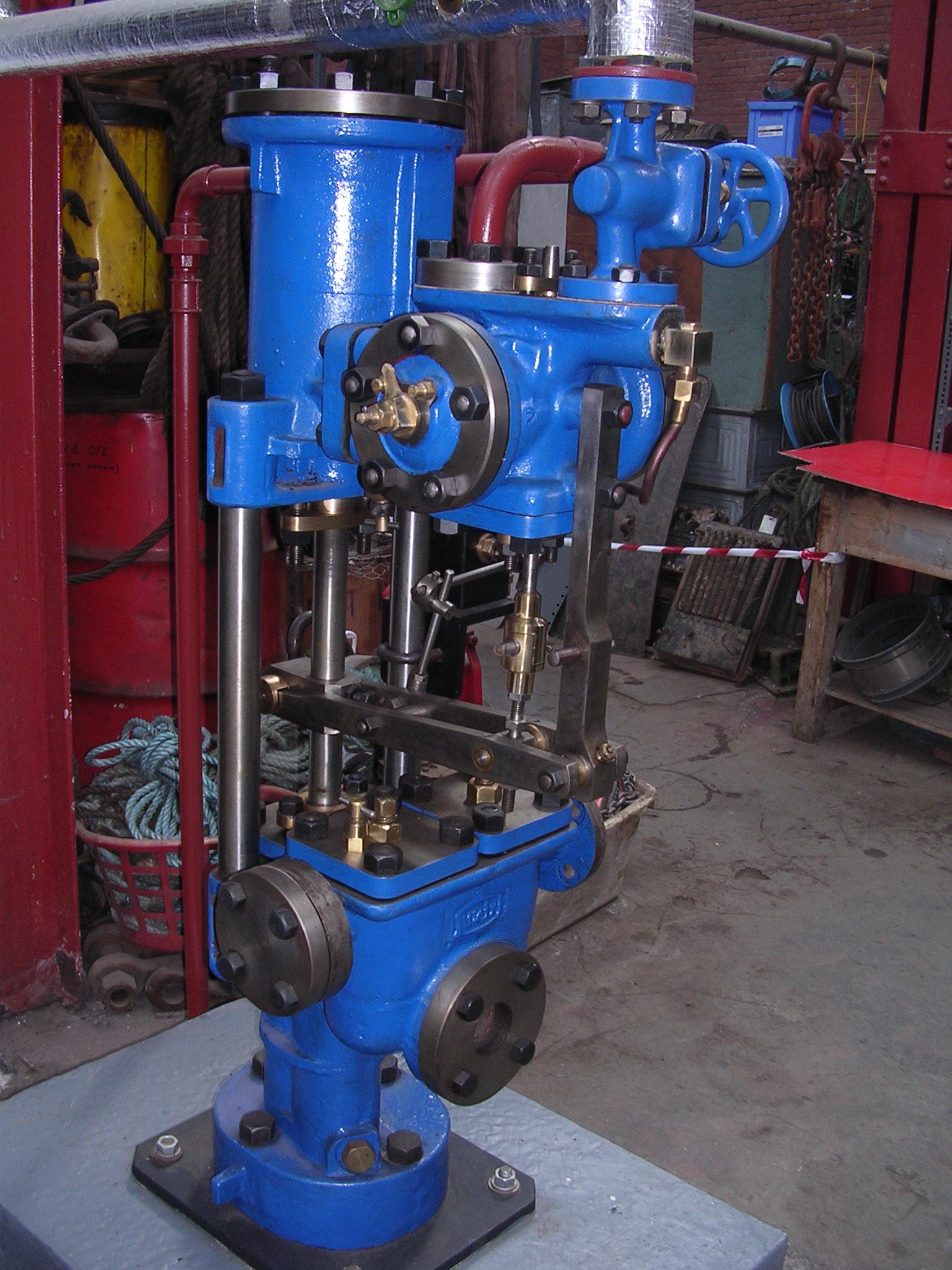

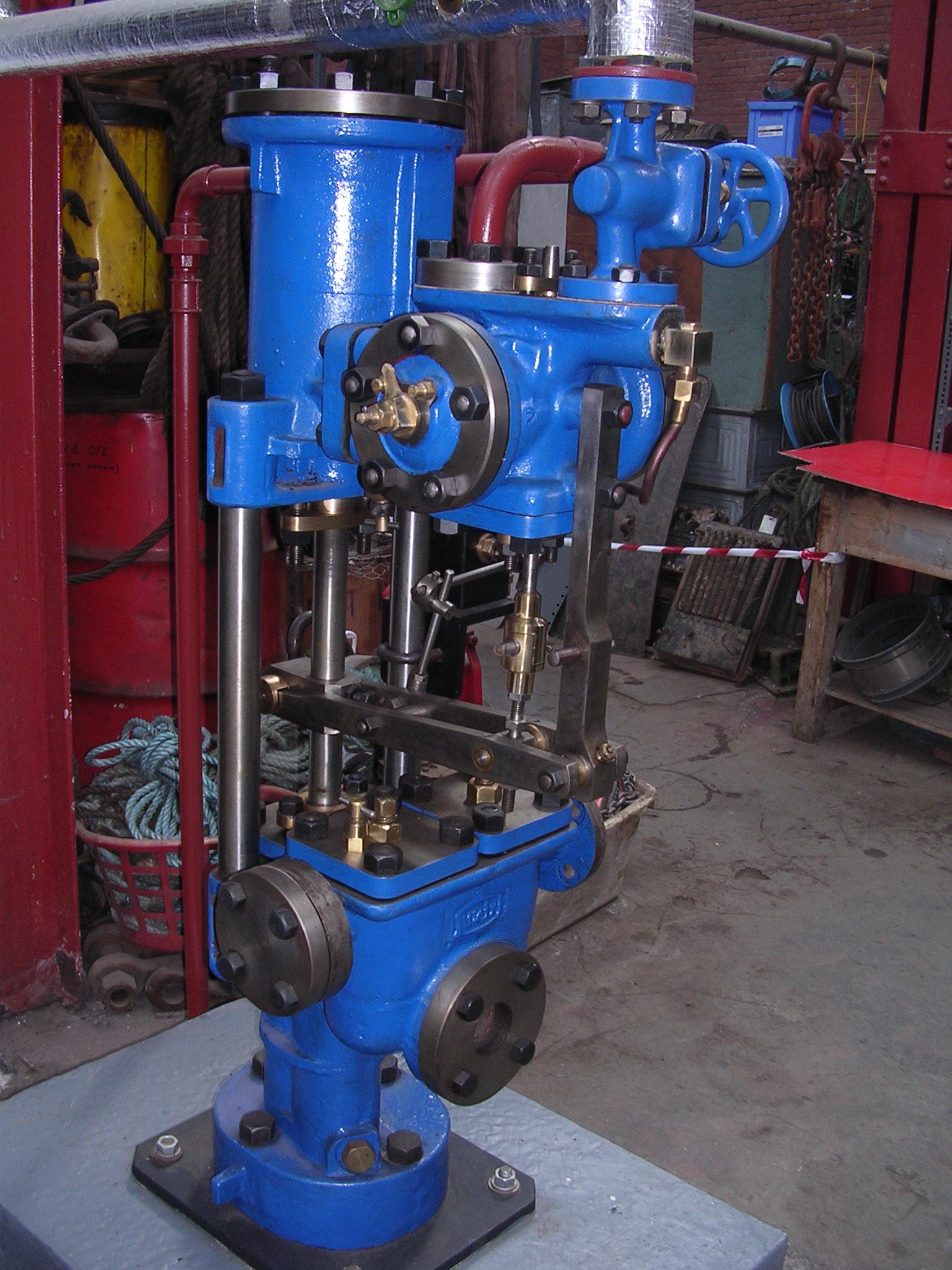

Steam locomotives and the steam engines used on ships and stationary applications such as

Steam locomotives and the steam engines used on ships and stationary applications such as power plant

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the electricity generation, generation of electric power. Power stations are generally connected to an el ...

s also require feedwater pumps. In this situation, though, the pump was often powered using a small steam engine that ran using the steam produced by the boiler. A means had to be provided, of course, to put the initial charge of water into the boiler (before steam power was available to operate the steam-powered feedwater pump). The pump was often a positive displacement pump that had steam valves and cylinders at one end and feedwater cylinders at the other end; no crankshaft was required.

Duplex steam pump

A duplex steam pump has two sets of steam and water cylinders. They are not physically connected but the steam valves on the first pump are operated by the movement of the second pump's piston rod, and vice versa. The result is that there are no "dead spots" and the pump is always self-starting.Jet injector

An injector pump uses theVenturi effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista ...

and steam condensation to deliver water to a boiler.

See also

*Boiler feedwater

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the ma ...

References

{{steam engine configurations Fluid dynamics Pumps Steam boiler components Boilers