Breweries on:

[Wikipedia]

[Google]

[Amazon]

A brewery or brewing company is a business that makes and sells beer. The place at which beer is commercially made is either called a brewery or a beerhouse, where distinct sets of

Beer may have been known in

Beer may have been known in

Breweries, as production facilities reserved for making beer, did not emerge until monasteries and other

Breweries, as production facilities reserved for making beer, did not emerge until monasteries and other

Breweries today are made predominantly of

Breweries today are made predominantly of

their website

BrewersAssociation.org

Craft brewer definition from the Brewers association. * ''Straub Brewery'' By John Schlimm, Arcadia Publishing, 2005, {{Authority control Manufacturing plants

brewing equipment

Brewing equipment is the vessels and tools used to brew beer, which usually includes systems of saccharification, fermentation, refrigeration and clean-in-place.

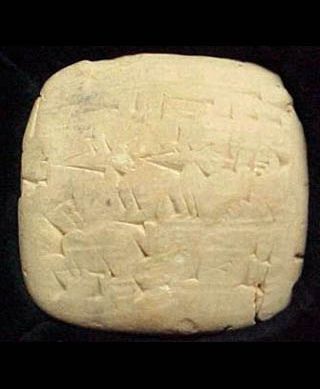

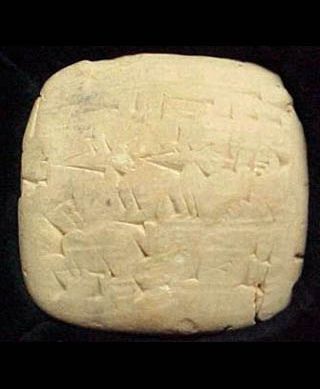

Archaeologists uncovered ancient beer brewing equipment in an underground room bu ...

are called plant. The commercial brewing

Brewing is the production of beer by steeping a starch source (commonly cereal grains, the most popular of which is barley) in water and #Fermenting, fermenting the resulting sweet liquid with Yeast#Beer, yeast. It may be done in a brewery ...

of beer has taken place since at least 2500 BC; in ancient Mesopotamia, brewers derived social sanction and divine protection from the goddess Ninkasi. Brewing was initially a cottage industry

The putting-out system is a means of subcontracting work. Historically, it was also known as the workshop system and the domestic system. In putting-out, work is contracted by a central agent to subcontractors who complete the project via remote ...

, with production taking place at home; by the ninth century, monasteries and farms would produce beer on a larger scale, selling the excess; and by the eleventh and twelfth centuries larger, dedicated breweries with eight to ten workers were being built.

The diversity of size in breweries is matched by the diversity of processes, degrees of automation, and kinds of beer produced in breweries. A brewery is typically divided into distinct sections, with each section reserved for one part of the brewing

Brewing is the production of beer by steeping a starch source (commonly cereal grains, the most popular of which is barley) in water and #Fermenting, fermenting the resulting sweet liquid with Yeast#Beer, yeast. It may be done in a brewery ...

process.

History

Beer may have been known in

Beer may have been known in Neolithic Europe

The European Neolithic is the period when Neolithic (New Stone Age) technology was present in Europe, roughly between 7000 BCE (the approximate time of the first farming societies in Greece) and c.2000–1700 BCE (the beginning of the Bronze Age ...

and was mainly brewed on a domestic scale.

In some form, it can be traced back almost 5000 years to Mesopotamian writings describing daily rations of beer and bread to workers. Before the rise of production breweries, the production of beer took place at home and was the domain of women, as baking and brewing were seen as "women's work".

Industrialization

Breweries, as production facilities reserved for making beer, did not emerge until monasteries and other

Breweries, as production facilities reserved for making beer, did not emerge until monasteries and other Christian

Christians () are people who follow or adhere to Christianity, a monotheistic Abrahamic religion based on the life and teachings of Jesus Christ. The words ''Christ'' and ''Christian'' derive from the Koine Greek title ''Christós'' (Χρι ...

institutions started producing beer not only for their own consumption but also to use as payment. This industrialization of brewing shifted the responsibility of making beer to men.

The oldest, still functional, brewery in the world is believed to be the German state-owned Weihenstephan brewery in the city of Freising, Bavaria. It can trace its history back to 1040 AD. The nearby Weltenburg Abbey brewery, can trace back its beer-brewing tradition to at least 1050 AD. The Žatec brewery in the Czech Republic claims it can prove that it paid a beer tax in 1004 AD.

Early breweries were almost always built on multiple stories, with equipment on higher floors used earlier in the production process, so that gravity could assist with the transfer of product from one stage to the next. This layout often is preserved in breweries today, but mechanical pumps allow more flexibility in brewery design. Early breweries typically used large copper vats in the brewhouse, and fermentation

Fermentation is a metabolic process that produces chemical changes in organic substrates through the action of enzymes. In biochemistry, it is narrowly defined as the extraction of energy from carbohydrates in the absence of oxygen. In food ...

and packaging took place in lined wooden containers. Such breweries were common until the Industrial Revolution, when better materials became available, and scientific advances led to a better understanding of the brewing process. Today, almost all brewery equipment is made of stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corros ...

.

During the Industrial Revolution, the production of beer moved from artisanal manufacture to industrial manufacture, and domestic manufacture ceased to be significant by the end of the 19th century.

Major technological advances

A handful of major breakthroughs have led to the modern brewery and its ability to produce the same beer consistently. Thesteam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be trans ...

, vastly improved in 1775 by James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was fun ...

, brought automatic stirring mechanisms and pumps into the brewery. It gave brewers the ability to mix liquids more reliably while heating, particularly the mash, to prevent scorching, and a quick way to transfer liquid from one container to another. Almost all breweries now use electric-powered stirring mechanisms and pumps. The steam engine also allowed the brewer to make greater quantities of beer, as human power was no longer a limiting factor in moving and stirring.

Carl von Linde, along with others, is credited with developing the refrigeration machine in 1871. Refrigeration allowed beer to be produced year-round, and always at the same temperature. Yeast is very sensitive to temperature, and, if a beer were produced during summer, the yeast would impart unpleasant flavours onto the beer. Most brewers would produce enough beer during winter to last through the summer, and store it in underground cellars, or even caves, to protect it from summer's heat.

The discovery of microbe

A microorganism, or microbe,, ''mikros'', "small") and ''organism'' from the el, ὀργανισμός, ''organismós'', "organism"). It is usually written as a single word but is sometimes hyphenated (''micro-organism''), especially in olde ...

s by Louis Pasteur

Louis Pasteur (, ; 27 December 1822 – 28 September 1895) was a French chemist and microbiologist renowned for his discoveries of the principles of vaccination, microbial fermentation and pasteurization, the latter of which was named afte ...

was instrumental in the control of fermentation. The idea that yeast was a microorganism that worked on wort to produce beer led to the isolation of a single yeast cell by Emil Christian Hansen. Pure yeast cultures allow brewers to pick out yeasts for their fermentation characteristics, including flavor profiles and fermentation ability. Some breweries in Belgium, however, still rely on "spontaneous" fermentation for their beers (see lambic

Lambic () is a type of beer brewed in the Pajottenland region of Belgium southwest of Brussels and in Brussels itself since the 13th century. Types of lambic beers include gueuze, kriek lambic and framboise. Lambic differs from most other beers ...

).

The development of hydrometer

A hydrometer or lactometer is an instrument used for measuring density or relative density of liquids based on the concept of buoyancy. They are typically calibrated and graduated with one or more scales such as specific gravity.

A hydrometer ...

s and thermometers changed brewing by allowing the brewer more control of the process, and greater knowledge of the results.

The modern brewery

Breweries today are made predominantly of

Breweries today are made predominantly of stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corros ...

, although vessels often have a decorative copper cladding for a nostalgic look. Stainless steel has many favourable characteristics that make it a well-suited material for brewing equipment. It imparts no flavour in beer, it reacts with very few chemicals, which means almost any cleaning solution can be used on it (concentrated chlorine leachbeing a notable exception).

Heating in the brewhouse usually is achieved through pressurized steam, although direct-fire systems are not unusual in small breweries. Likewise, cooling in other areas of the brewery is typically done by cooling jackets on tanks, which allow the brewer to control precisely the temperature on each tank individually, although whole-room cooling is also common.

Today, modern brewing plants perform myriad analyses on their beers for quality control purposes. Shipments of ingredients are analyzed to correct for variations. Samples are pulled at almost every step and tested for xygencontent, unwanted microbial infections, and other beer-aging compounds. A representative sample of the finished product often is stored for months for comparison, when complaints are received.

Brewing process

Brewing is typically divided into 9 steps: milling, malting, mashing, lautering, boiling, fermenting, conditioning, filtering, and filling.Mashing

In brewing and distilling, mashing is the process of combining a mix of ground grains – typically malted barley with supplementary grains such as corn, sorghum, rye, or wheat – known as the "grain bill" with water and then heating the mixtu ...

is the process of mixing milled, usually malt

Malt is germinated cereal grain that has been dried in a process known as " malting". The grain is made to germinate by soaking in water and is then halted from germinating further by drying with hot air.

Malted grain is used to make beer, wh ...

ed, grain with water, and heating it with rests at certain temperatures to allow enzymes in the malt to break down the starch

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants for energy storage. Worldwide, it is the most common carbohydrate in human diets ...

es in the grain into sugar

Sugar is the generic name for sweet-tasting, soluble carbohydrates, many of which are used in food. Simple sugars, also called monosaccharides, include glucose, fructose, and galactose. Compound sugars, also called disaccharides or double ...

s, especially maltose

}

Maltose ( or ), also known as maltobiose or malt sugar, is a disaccharide formed from two units of glucose joined with an α(1→4) bond. In the isomer isomaltose, the two glucose molecules are joined with an α(1→6) bond. Maltose is the two- ...

. Lautering

Lautering () is the beer brewing process that separates the mash into clear liquid wort and residual grain. Lautering usually consists of three steps: mashout, recirculation, and sparging.

Mashout

Mashout is the term for raising the temperature ...

is the separation of the extracts won during mashing from the spent grain to create wort. It is achieved in either a lauter tun, a wide vessel with a false bottom, or a mash filter, a plate-and-frame filter designed for this kind of separation. Lautering has two stages: first wort run-off, during which the extract is separated in an undiluted state from the spent grains, and sparging

Sparging may refer to:

*Sparging (chemistry), a process in which a gas is bubbled through a liquid to remove other gases or volatile compounds

*Air sparging, a remediation process in which air is pushed through contaminated water or soil to remove ...

, in which extract that remains with the grains is rinsed off with hot water.

Boiling the wort ensures its sterility, helping to prevent contamination with undesirable microbes. During the boil, hops

Hops are the flowers (also called seed cones or strobiles) of the hop plant ''Humulus lupulus'', a member of the Cannabaceae family of flowering plants. They are used primarily as a bittering, flavouring, and stability agent in beer, to whi ...

are added, which contribute aroma and flavour compounds to the beer, especially their characteristic bitterness. Along with the heat of the boil, they cause proteins in the wort to coagulate and the pH of the wort to fall, and they inhibit the later growth of certain bacteria. Finally, the vapours produced during the boil volatilize off-flavours, including dimethyl sulfide

Dimethyl sulfide (DMS) or methylthiomethane is an organosulfur compound with the formula (CH3)2S. Dimethyl sulfide is a flammable liquid that boils at and has a characteristic disagreeable odor. It is a component of the smell produced from cook ...

precursors. The boil must be conducted so that it is even and intense. The boil lasts between 60 and 120 minutes, depending on its intensity, the hop addition schedule, and volume of wort the brewer expects to evaporate

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when humidi ...

.

;Fermenting

Fermentation

Fermentation is a metabolic process that produces chemical changes in organic substrates through the action of enzymes. In biochemistry, it is narrowly defined as the extraction of energy from carbohydrates in the absence of oxygen. In food ...

begins as soon as yeast is added to the cooled wort. This is also the point at which the product is first called beer. It is during this stage that fermentable sugars won from the malt (maltose, maltotriose, glucose, fructose and sucrose) are metabolized into alcohol

Alcohol most commonly refers to:

* Alcohol (chemistry), an organic compound in which a hydroxyl group is bound to a carbon atom

* Alcohol (drug), an intoxicant found in alcoholic drinks

Alcohol may also refer to:

Chemicals

* Ethanol, one of sev ...

and carbon dioxide. Fermentation tanks come in many shapes and sizes, from enormous cylindroconical vessels that can look like storage silos, to glass carboys used by homebrewers. Most breweries today use cylindroconical vessels (CCVs), which have a conical bottom and a cylindrical top. The cone's aperture is typically around 70°, an angle that will allow the yeast to flow smoothly out through the cone's apex at the end of fermentation, but is not so steep as to take up too much vertical space. CCVs can handle both fermenting and conditioning in the same tank. At the end of fermentation, the yeast and other solids have fallen to the cone's apex can be simply flushed out through a port at the apex. Open fermentation vessels are also used, often for show in brewpubs, and in Europe in wheat beer fermentation. These vessels have no tops, making it easy to harvest top-fermenting yeasts. The open tops of the vessels increase the risk of contamination, but proper cleaning procedures help to control the risk.

Fermentation tanks are typically made of stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corros ...

. Simple cylindrical tanks with beveled ends are arranged vertically, and conditioning tanks are usually laid out horizontally. A very few breweries still use wooden vats for fermentation but wood is difficult to keep clean and infection-free and must be repitched often, perhaps yearly. After high kräusen, the point at which fermentation is most active and copious foam is produced, a valve known in German as the ''spundapparat'' may be put on the tanks to allow the carbon dioxide produced by the yeast to naturally carbonate the beer. This bung device can regulate the pressure to produce different types of beer; greater pressure produces a more carbonated beer.

;Conditioning

When the sugars in the fermenting beer have been almost completely digested, the fermentation process slows and the yeast cells begin to die and settle at the bottom of the tank. At this stage, especially if the beer is cooled to around freezing, most of the remaining live yeast cells will quickly become dormant and settle, along with the heavier protein chains, due simply to gravity and molecular dehydration. Conditioning can occur in fermentation tanks with cooling jackets. If the whole fermentation cellar is cooled, conditioning must be done in separate tanks in a separate cellar. Some beers are conditioned only lightly, or not at all. An active yeast culture from an ongoing batch may be added to the next boil after a slight chilling in order to produce fresh and highly palatable beer in mass quantity.

;Filtering

Filtering the beer stabilizes flavour and gives it a polished, shiny look. It is an optional process. Many craft brewers simply remove the coagulated and settled solids and forgo active filtration. In localities where a tax assessment is collected by government pursuant to local laws, any additional filtration may be done using an active filtering system, the filtered product finally passing into a calibrated vessel for measurement just after any cold conditioning and prior to final packaging where the beer is put into the containers for shipment or sale. The container may be a bottle, can

Can may refer to:

Containers

* Aluminum can

* Drink can

* Oil can

* Steel and tin cans

* Trash can

* Petrol can

* Metal can (disambiguation)

Music

* Can (band), West Germany, 1968

** ''Can'' (album), 1979

* Can (South Korean band)

Other

* C ...

, of keg, cask or bulk tank.

Filters come in many types. Many use pre-made filtration media such as sheets or candles. Kieselguhr, a fine powder of diatomaceous earth

Diatomaceous earth (), diatomite (), or kieselgur/kieselguhr is a naturally occurring, soft, siliceous sedimentary rock that can be crumbled into a fine white to off-white powder. It has a particle size ranging from more than 3 μm to le ...

, can be introduced into the beer and circulated through screens to form a filtration bed. Filtration ratings are divided into rough, fine, and sterile. Rough filters remove yeasts and other solids, leaving some cloudiness, while finer filters can remove body and color. Sterile filters remove almost all microorganisms.

Brewing companies

Brewing companies range widely in the volume and variety of beer produced, ranging from small breweries to massive multinational conglomerates, like Molson Coors orAnheuser-Busch InBev

Anheuser-Busch InBev SA/NV, commonly known as AB InBev, is an American-Belgian multinational drink and brewing company based in Leuven, Belgium. AB InBev has a global functional management office in New York City, and regional headquarters ...

, that produce hundreds of million

One million (1,000,000), or one thousand thousand, is the natural number following 999,999 and preceding 1,000,001. The word is derived from the early Italian ''millione'' (''milione'' in modern Italian), from ''mille'', "thousand", plus the au ...

s of barrels annually. There are organizations that assist the development of brewing, such as the Siebel Institute of Technology in the United States and the Institute of Brewing and Distilling in the UK. In 2012 the four largest brewing companies (Anheuser-Busch InBev

Anheuser-Busch InBev SA/NV, commonly known as AB InBev, is an American-Belgian multinational drink and brewing company based in Leuven, Belgium. AB InBev has a global functional management office in New York City, and regional headquarters ...

, SABMiller

SABMiller plc was a South African multinational brewing and beverage company headquartered in Woking, England on the outskirts of London until 10 October 2016 when it was acquired by Anheuser-Busch InBev. Prior to that date, it was the world's ...

, Heineken International, and Carlsberg Group) controlled 50% of the market The biggest brewery in the world is the Belgian-Brazilian company Anheuser-Busch InBev

Anheuser-Busch InBev SA/NV, commonly known as AB InBev, is an American-Belgian multinational drink and brewing company based in Leuven, Belgium. AB InBev has a global functional management office in New York City, and regional headquarters ...

.

In the United States, there were 69,359 people employed in breweries in 2017. This is up from 27,805 in 2001.

Some commonly used descriptions of breweries are:

* Microbrewery

Craft beer is a beer that has been made by craft breweries. They produce smaller amounts of beer, typically less than large breweries, and are often independently owned. Such breweries are generally perceived and marketed as having an emphasis o ...

– A name used since the 1970s for a small, often independently owned brewery. In the 21st century the largely synonymous term craft brewery is also used.

* Brewpub – A brewery whose beer is brewed primarily on the same site from which it is sold to the public, such as a pub or restaurant

A restaurant is a business that prepares and serves food and drinks to customers. Meals are generally served and eaten on the premises, but many restaurants also offer take-out and food delivery services. Restaurants vary greatly in appearan ...

. In the United States, if the amount of beer that a brewpub distributes off-site exceeds 75% it may also be described as a craft or microbrewery.

* Farm brewery – A farm brewery, or farmhouse brewery, is a brewery that primarily brews its beer on a farm. Crops and other ingredients grown on the farm, such as barley, wheat, rye, hops, herbs, spices, and fruits are used in the beers brewed. A farmhouse brewery is similar in concept to a vineyard growing grapes to make wine at the vineyard.

* Regional brewery – An established term for a brewery that supplies beer in a fixed geographical location.

* Macrobrewery or Megabrewery – Terms for a brewery, too large or economically diversified to be a microbrewery, which sometimes carry a negative connotation.

Contract brewing

Contract brewing –When one brewery hires another brewery to produce its beer. The contracting brewer generally handles all of the beer's marketing, sales, and distribution, while leaving the brewing and packaging to the producer-brewery (which confusingly may also be referred to as a contract brewer). Often the contract brewing is performed when a small brewery can not supply enough beer to meet demands and contracts with a larger brewery to help alleviate their supply issues. Some breweries do not own a brewing facility, these contract brewers have been criticized by traditional brewing companies for avoiding the costs associated with a physical brewery.Gypsy brewing

Gypsy, or nomad, brewing usually falls under the category of contract brewing. Gypsy breweries generally do not have their own equipment or premises. They operate on a temporary or itinerant basis out of the facilities of another brewery, generally making "one-off" special occasion beers. The trend of gypsy brewing spread early in Scandinavia. Their beers and collaborations later spread to America and Australia. Gypsy brewers typically use facilities of larger makers withexcess capacity

Capacity utilization or capacity utilisation is the extent to which a firm or nation employs its installed productive capacity. It is the relationship between output that ''is'' produced with the installed equipment, and the potential output whic ...

.

Prominent examples include Pretty Things, Stillwater Artisanal Ales, Gunbarrel Brewing Company, Mikkeller, and Evil Twin. For example, one of Mikkeller's founders, Mikkel Borg Bjergsø, has traveled around the world between 2006 and 2010, brewing more than 200 different beers at other breweries.

Sponsorship

Breweries and football have had a symbiotic relationship since the very beginnings of the game. The English Football League was founded in 1888, and by the next decade several teams already had their own brewery sponsor. In return for their financial support, the breweries were given concessions to sell beer to spectators and advertise their products in stadiums. The most outwardly visible sign of sponsorship are the adverts printed on football team's kit. For example, Liverpool F.C. had the logo of the Denmark-based Carlsberg brewery group on the front of its shirts for nearly twenty years, from 1992 to 2010. Nowadays major brewing corporations are involved in sponsorship on a number of different levels. The prevailing trend is for the leading brand not to be linked to individual teams; rather, they achieve visibility as sponsor of tournaments and leagues, so all fans can engage with them regardless of which team they support. Heineken sponsors the UEFA Champions League with its namesake lager; Carlsberg sponsors the English Premier League as well as the 2012 and 2016 UEFA European Championships. Meanwhile, the AB InBev Group supports the FA Cup and the FIFA World Cup.Head brewer/brewmaster

The head brewer (UK) or brewmaster (US) is in charge of the production of beer. The major breweries employ engineers with achemistry

Chemistry is the science, scientific study of the properties and behavior of matter. It is a natural science that covers the Chemical element, elements that make up matter to the chemical compound, compounds made of atoms, molecules and ions ...

/ biotechnology background.

Brewmasters may have had a formal education in the subject from institutions such as the Siebel Institute of Technology, VLB Berlin, Heriot-Watt University

Heriot-Watt University ( gd, Oilthigh Heriot-Watt) is a public research university based in Edinburgh, Scotland. It was established in 1821 as the School of Arts of Edinburgh, the world's first mechanics' institute, and subsequently granted univ ...

, American Brewers Guild, University of California at Davis, University of Wisconsin, Olds College or Niagara College. They may hold membership in professional organisations such as the Brewers Association, Master Brewers Association, American Society of Brewing Chemists, the Institute of Brewing and Distilling, and the Society of Independent Brewers. Depending on a brewery's size, a brewer may need anywhere from five to fifteen years of professional experience before becoming a brewmaster.

See also

*Beer and breweries by region

This is a list of articles and categories dealing with beer and breweries by region: the breweries and beers in various regions. Beer is the world's most widely consumed alcoholic drink, and is the third-most popular drink overall, after water and ...

* Breweriana

Breweriana refers to articles containing a brewery or brand name, such as beer cans, beer bottles, bottle openers, beer labels, tin signs, beer mats, beer trays, beer tap, wooden cases and neon signs.

United States

In the US, the National Ass ...

—the hobby of brewery advertising collecting

* List of breweries in the United States

* List of microbreweries

* Tower brewery

References

Further reading

* : ''Technology Brewing and Malting'', Wolfgang Kunze, 2004, 3rd revised edition, VLB Berlin. Available atheir website

BrewersAssociation.org

Craft brewer definition from the Brewers association. * ''Straub Brewery'' By John Schlimm, Arcadia Publishing, 2005, {{Authority control Manufacturing plants