|

Zero-ohm Link

Zero-ohm axial lead resistor Zero-ohm surface-mount resistor A zero-ohm link or zero-ohm resistor is a wire link packaged in the same physical package format as a resistor. It is used to connect traces on a printed circuit board (PCB). This format allows it to be placed on the circuit board using the same automated equipment used to place other resistors, instead of requiring a separate machine to install a jumper or other wire. Zero-ohm resistors may be packaged like cylindrical resistors, or like surface-mount resistors. Use One use is to allow traces on the same side of a PCB to cross: one trace has a zero-ohm resistor while other traces can run in between the leads/pads of the zero-ohm resistor, avoiding contact with the first trace. Zero ohm resistors can also be used as configuration jumpers or in places where it should be easy to disconnect and reconnect electrical connections within a PCB to diagnose problems. The resistance is only approximately zero; only a maxi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vishay Intertechnology

Vishay Intertechnology, Inc. is an American manufacturer of discrete semiconductors and passive electronic components founded by Polish-born businessman Felix Zandman. Vishay has manufacturing plants in Israel, Asia, Europe, and the Americas where it produces rectifiers, diodes, MOSFETs, optoelectronics, selected integrated circuits, resistors, capacitors, and inductors. Vishay Intertechnology revenues for 2021 were $3.24 billion. As of December 31, 2021, Vishay Intertechnology had approximately 22,800 full-time employees. Vishay is one of the world's foremost manufacturers of power MOSFETs. They have a wide range of power electronic applications, including portable information appliances, internet communications infrastructure, power integrated circuits, cell phones, and notebook computers. History Vishay Intertechnology was founded in 1962 by Holocaust survivor Polish-born Dr. Felix Zandman. The company was named after Zandman's ancestral village in present-day Lithuania ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shunt (electrical)

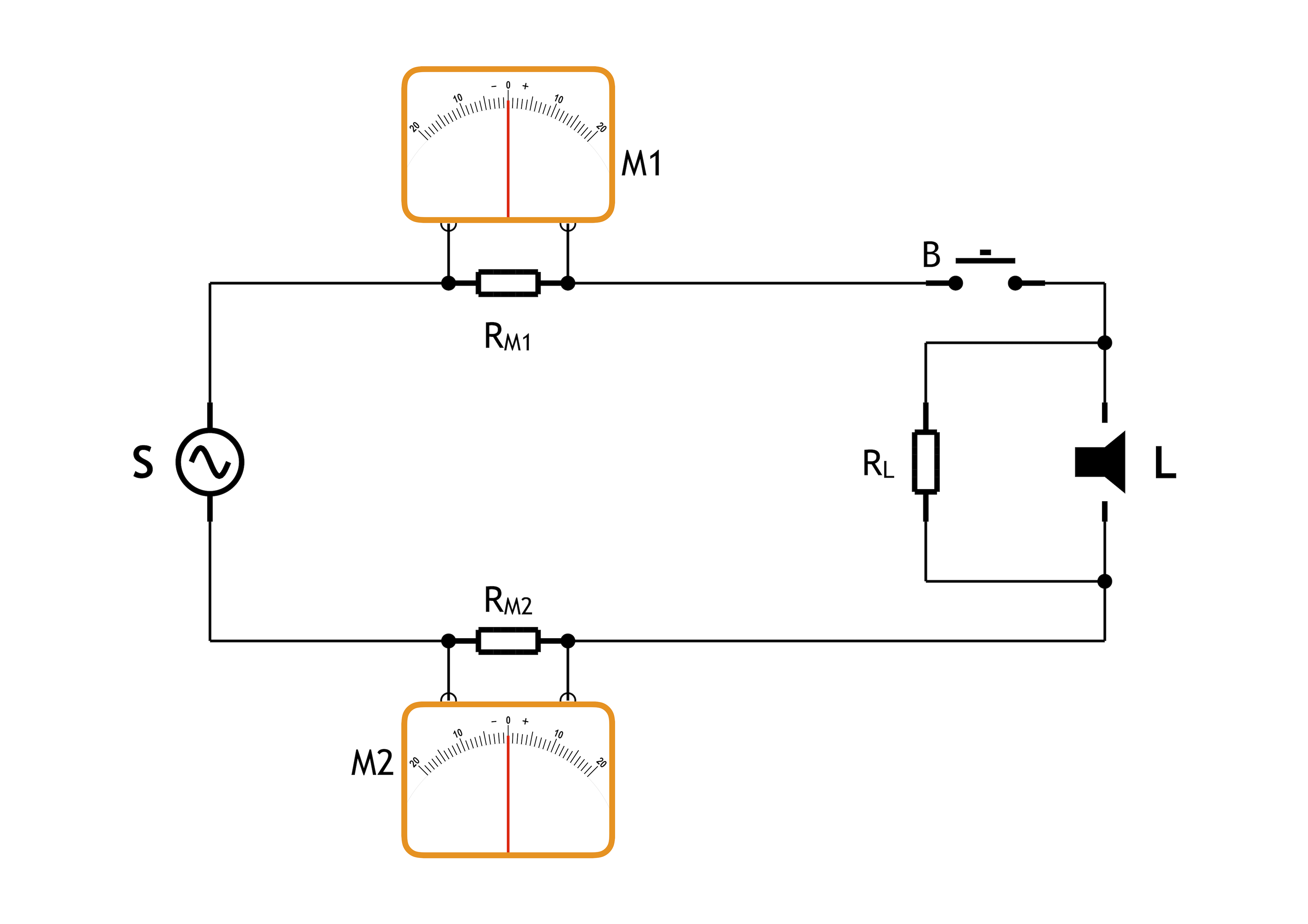

In electronics, a shunt is a device that creates a low- resistance path for electric current, to allow it to pass around another point in the circuit.Rudolf F. Graf, ''Modern dictionary of Electronics'', Mc-Graw Hill, 1968 Library of Congress 68-13873 ''Shunt'' page 454. The origin of the term is in the verb 'to shunt' meaning to turn away or follow a different path. Defective device bypass One example is in miniature Christmas lights which are wired in series. When the filament burns out in one of the incandescent light bulbs, the full line voltage appears across the burnt out bulb. A shunt resistor, which has been connected in parallel across the filament before it burnt out, will then short out to bypass the burnt filament and allow the rest of the string to light. If too many lights burn out however, a shunt will also burn out, requiring the use of a multimeter to find the point of failure. Photovoltaics In photovoltaics, the term is widely used to describe an ''unwan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thick Film

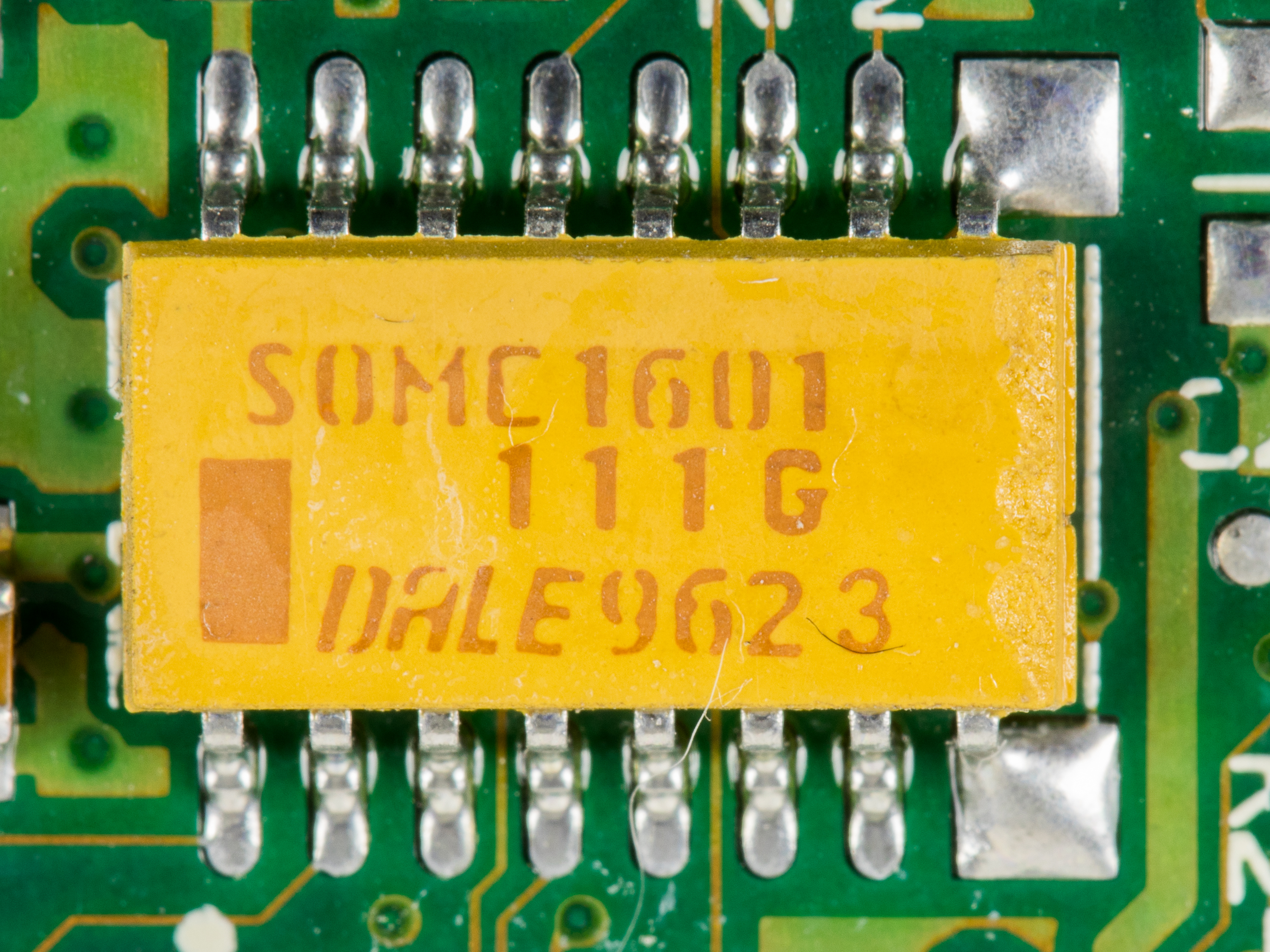

Thick-film technology is used to produce electronic devices/modules such as surface mount devices modules, hybrid integrated circuits, heating elements, integrated passive devices and sensors. Main manufacturing technique is screen printing (stenciling), which in addition to use in manufacturing electronic devices can also be used for various graphic reproduction targets. It became one of the key manufacturing/miniaturisation techniques of electronic devices/modules during 1950s. Typical film thickness – manufactured with thick film manufacturing processes for electronic devices – is 0.0001 to 0.1 mm. Thick-film circuits/modules are widely used in the automotive industry, both in sensors, e.g. mixture of fuel/air, pressure sensors, engine and gearbox controls, sensor for releasing airbags, ignitors to airbags; common is that high reliability is required, often extended temperature range also along massive thermocycling of circuits without failure. Other application areas ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface-mount Technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced the through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resistor Color Code

An electronic color code or electronic colour code (see spelling differences) is used to indicate the values or ratings of electronic components, usually for resistors, but also for capacitors, inductors, diodes and others. A separate code, the 25-pair color code, is used to identify wires in some telecommunications cables. Different codes are used for wire leads on devices such as transformers or in building wiring. History Before industry standards were established, each manufacturer used their own unique system for color coding or marking their components. In the 1920s, the RMA resistor color code was developed by the Radio Manufacturers Association (RMA) as a fixed resistor coloring code marking. In 1930, the first radios with RMA color-coded resistors were built. Over many decades, as the organization name changed (RMA, RTMA, RETMA, EIA) so was the name of the code. Though known most recently as EIA color code, the four name variations are found in books, magazines, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Through-hole

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, either by manual assembly (hand placement) or by the use of automated insertion mount machines. History Through-hole technology almost completely replaced earlier electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology (SMT) became popular in the mid 1980s, every component on a typical PCB was a through-hole component. PCBs initially had tracks printed on one side only, later both sides, then multi-layer boards were in use. Through holes became plated-through holes (PTH) in order for the components to make contact with the required conductive layers. Plated-through holes are no longer required with SMT boards for making the component connections, bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axial-lead

In electronics, through-hole technology (also spelled "thru-hole") is a manufacturing scheme in which leads on the components are inserted through holes drilled in printed circuit boards (PCB) and soldered to pads on the opposite side, either by manual assembly (hand placement) or by the use of automated insertion mount machines. History Through-hole technology almost completely replaced earlier electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology (SMT) became popular in the mid 1980s, every component on a typical PCB was a through-hole component. PCBs initially had tracks printed on one side only, later both sides, then multi-layer boards were in use. Through holes became plated-through holes (PTH) in order for the components to make contact with the required conductive layers. Plated-through holes are no longer required with SMT boards for making the component connections, bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mouser Electronics

Mouser Electronics is a global distributor of semiconductors and electronic components. With over $3 billion in annual revenue, Mouser is ranked as the seventh largest electronic component distributor in the world. The company has 27 locations globally and more than 3,200 employees. Mouser is part of the Berkshire Hathaway family of companies. The company’s global headquarters and distribution center rests on a large 78-acre campus in the DFW Metroplex, Texas. Facilities span one million square feet to accommodate inventory for over a million unique SKUs consisting of new products and technologies from over 1,200 manufacturer brands, including Texas Instruments, Intel, TE Connectivity and Analog Devices. Mouser’s global distribution center is active 24 hours a day to manage tens of thousands of orders each day. Distribution center staff processes and ships to over 650,000 customers in over 223 countries and/or territories. Mouser has made capital investments in 120 Verti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rohm

(styled as ROHM) is a Japanese electronic parts manufacturer based in Kyoto, Japan. Rohm was incorporated as Toyo Electronics Industry Corporation by Kenichiro Sato (佐藤 研一郎) on September 17, 1958. The company was originally called R.ohm, which was derived from R for resistors, the original product, plus ohm, the unit of measure for resistance. The name of the company was officially changed to Rohm in 1979 and then changed again to Rohm Semiconductor in January 2009. When Rohm was established, resistors were its main product. Later, the company began manufacturing semiconductors. ICs and discrete semiconductors now account for about 80% of Rohm's revenue. Through 2012, Rohm was among the top 20 semiconductor sales leaders. International expansion In 2016, Rohm started the construction of their production facility in Kelantan, Malaysia and commenced the operation on April 2017. A few years later in 2022, Rohm expanded their facility by approximately 1.5 times b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jumper (computing)

In electronics and particularly computing, a jumper is a short length of conductor used to close, open or bypass part of an electronic circuit. They are typically used to set up or configure printed circuit boards, such as the motherboards of computers. The process of setting a jumper is often called strapping. A strapping option is a hardware configuration setting usually sensed only during power-up or bootstrapping of a device (or even a single chip). Design Jumper pins (points to be connected by the jumper) are arranged in groups called ''jumper blocks'', each group having at least one pair of contact points. An appropriately sized conductive sleeve called a jumper, or more technically, a shunt jumper, is slipped over the pins to complete the circuit. A two-pin jumper only allows to choose between two Boolean states, whereas a three-pin jumper allows to select between three states. Jumpers must be electrically conducting; they are usually encased in a non-conducti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)