|

Z-pinning

Z-pinning is a technique to insert reinforcing fibres (also called Z-pins or Z-fibres) along the Z-direction of continuous fibre-reinforced plastics. Z-pins can be made of metal or precured unidirectional composite fibres. It is designed for use within pre-preg technology; there is extensive experimental evidence that Z-pinning dramatically improves the resistance of the composite structure to delamination. The figure on the right shows a Z-pin inserted in between the fibres of the material. The pin spreads the fibres and creates an oval shaped gap that is filled with resin. The Z-pin prevents the composite from delamination. When a load is applied the cracks will typically form along the line of the opening. Benefits Z-pinning is a versatile technique that can be applied to many materials that will benefit from added strength and durability. They are especially effective when used in materials that are subject to delamination, because the Z-pins can counteract this proble ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cartesian Coordinate System

A Cartesian coordinate system (, ) in a plane is a coordinate system that specifies each point uniquely by a pair of numerical coordinates, which are the signed distances to the point from two fixed perpendicular oriented lines, measured in the same unit of length. Each reference coordinate line is called a ''coordinate axis'' or just ''axis'' (plural ''axes'') of the system, and the point where they meet is its ''origin'', at ordered pair . The coordinates can also be defined as the positions of the perpendicular projections of the point onto the two axes, expressed as signed distances from the origin. One can use the same principle to specify the position of any point in three-dimensional space by three Cartesian coordinates, its signed distances to three mutually perpendicular planes (or, equivalently, by its perpendicular projection onto three mutually perpendicular lines). In general, ''n'' Cartesian coordinates (an element of real ''n''-space) specify the point in an ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fibre-reinforced Plastic

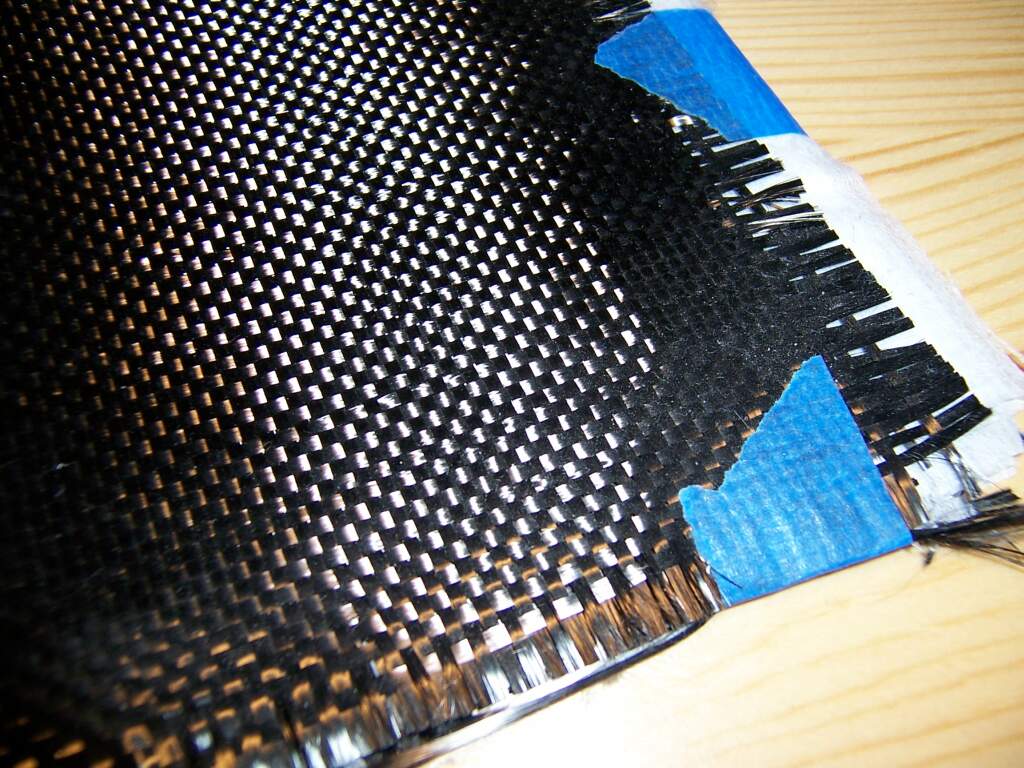

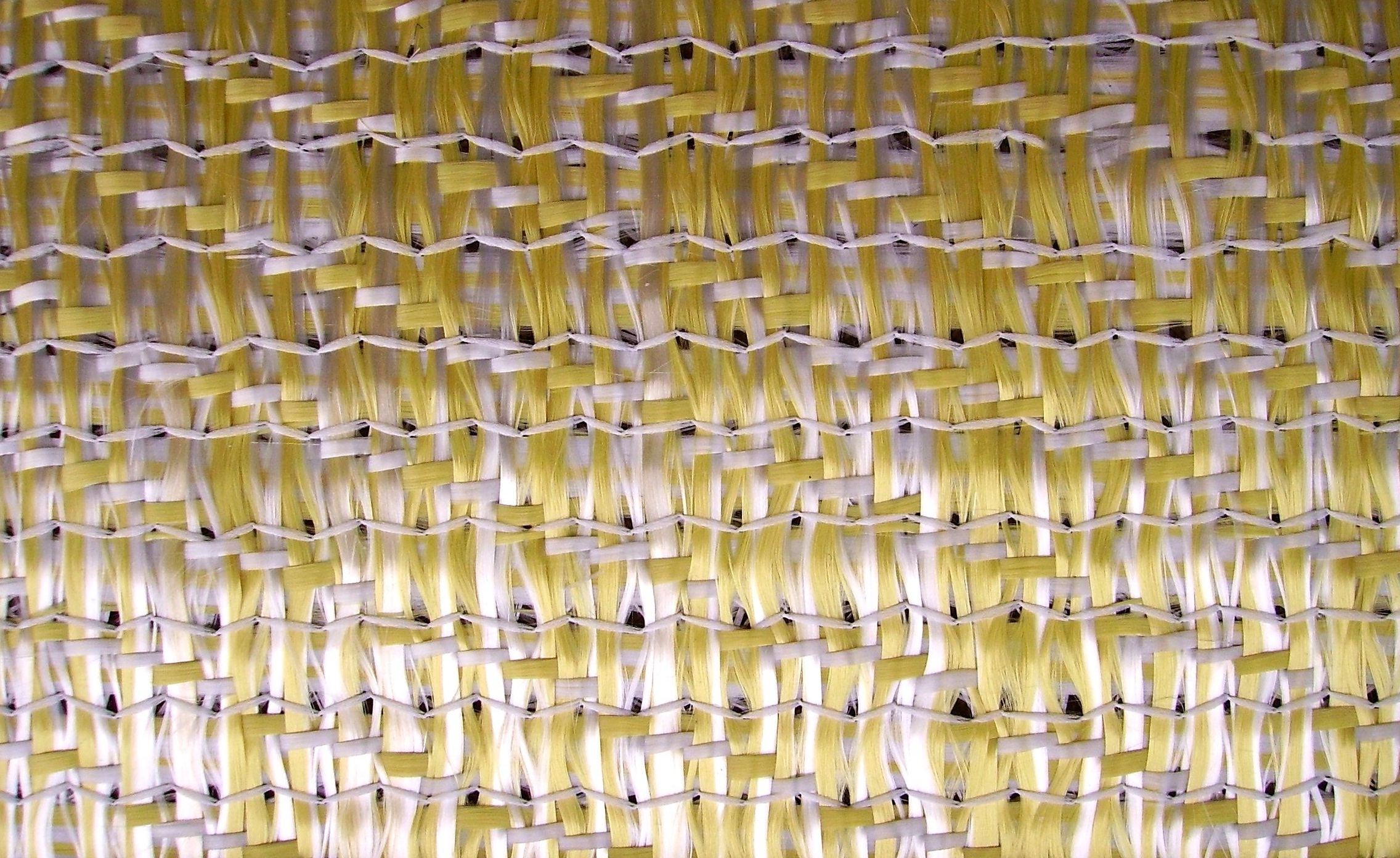

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass (in fibreglass), carbon (in carbon-fibre-reinforced polymer), aramid, or basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plastic. Composite plastics refers to those types of plastic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pre-preg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling; this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure. The main idea behind a pre-preg material is the use of anisotropic mechanical properties along the fibers, while the polymer matrix provides filling properties, keeping the fibers in a single system. Pre-preg allows one to impregnate the fibers on a flat workable surface, or rather in an industrial process, and then later ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Delamination

Delamination is a mode of failure where a material fractures into layers. A variety of materials including laminate composites and concrete can fail by delamination. Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3D printing which can fail from layer separation. Also, surface coatings such as paints and films can delaminate from the coated substrate. In laminated composites, the adhesion between layers often fails first causing the layers to separate. For example, in fiber-reinforced plastics, sheets of high strength reinforcement (e.g., carbon fiber, fiberglass) are bound together by a much weaker polymer matrix (e.g., epoxy). In particular, loads applied perpendicular to the high strength layers, and shear loads can cause the polymer matrix to fracture or the fiber reinforcement to debond from the polymer. Delamination also occurs in reinforced concrete when metal reinforcements near the surface corrode. The oxidized me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on naturally occurring resins. Plants secrete resins for their protective benefits in response to injury. The resin protects the plant from insects and pathogens. Resins confound a wide range of herbivores, insects, and pathogens, while the volatile phenolic compounds may attract benefactors such as parasitoids or predators of the herbivores that attack the plant. Composition Most plant resins are composed of terpenes. Specific components are alpha-pinene, beta-pinene, delta-3 carene, and sabinene, the monocyclic terpenes limonene and terpinolene, and smaller amounts of the tricyclic sesquiterpenes, longifolene, caryophyllene, and delta-cadinene. Some resins also contain a high proportion of resin acids. Rosins on the other hand are less ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Journal Of Reinforced Plastics And Composites

The ''Journal of Reinforced Plastics and Composites'' is a peer-reviewed scientific journal that covers research in the field of materials science, especially plastics and composites. The editor-in-chief is G. Springer (Stanford University). It was established in 1982 and is currently published by SAGE Publications. Abstracting and indexing The ''Journal of Reinforced Plastics and Composites'' is abstracted and indexed in Scopus, and the Science Citation Index Expanded. According to ''Journal Citation Reports'', its 2020 impact factor The impact factor (IF) or journal impact factor (JIF) of an academic journal is a scientometric index calculated by Clarivate that reflects the yearly mean number of citations of articles published in the last two years in a given journal, as i ... is 3.710. References External links * {{Official website, http://www.sagepub.com/journals/Journal201585/title SAGE Publishing academic journals English-language journals Biweekly journ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Fibers

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers. To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the fiber's long axis as the crystal alignment gives the fiber a high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow, which may be used by itself or woven into a fabric. Carbon f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffuser (automotive)

A diffuser, in an automotive context, is a shaped section of the car rear which improves the car's aerodynamic properties by enhancing the transition between the high-velocity airflow underneath the car and the much slower freestream airflow of the ambient atmosphere. It works by providing a space for the underbody airflow to decelerate and expand (in volume, as density is assumed to be constant at the speeds that cars travel) so that it does not cause excessive flow separation and drag, by providing a degree of " wake infill" or more accurately, pressure recovery. The diffuser itself accelerates the flow in front of it, which helps generate downforce. This is achieved by creating a change in velocity of the air flowing under the diffuser by giving it a rake angle which in turn generates a change in pressure and hence increases downforce. __TOC__ Overview When a diffuser is used, the air flows into the underbody from the front of the car, accelerates and reduces pressure. Ther ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curing (chemistry)

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols. Curing process During the curing process, single monomers and oligomers, mixed with or without a curing agent, react to form a tridimensional polymeric network. In the very first part of the reaction branches of molecules with various architectures are formed, and their molecular weight increases in time with the extent of the reaction until the network size is equal to the size of the system. The system has lost its solubility and its viscosity tends to infinite. The remaining molecules start to coexist with the macroscopic network until they react with the network creating other c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pultrusion

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls the material. A very early pultrusions type patent was filed by J.H. Watson in 1944. This was followed by M.J. Meek's filing of 1950. The first commercial pultrusions were provided by Glastic Company of Cleveland, Ohio under the patent filed in 1952 by Rodger B. White. The patent issued to W. B. Goldsworthy in 1959 helped initiate the promotion and knowledge spread within the industry. W. Brandt Goldsworthy is widely regarded as the inventor of pultrusion. Parallel to the work of Goldsworthy, who concentrated his work on unsaturated polyester resins, Ernst Kühne in Germany developed a quite similar process in 1954 based on epoxy resin. Invention, development and the issuance of patents continue in the pultrusion field through today. A la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a press. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)