|

Yarn Realisation

In textile spinning, yarn realisation (YR), or yarn recovery, is an operational parameter of yarn manufacturing. It is the percentage conversion of raw material to finished yarn. The rest of the waste fibers with less value are compared to the weight of the produced yarn from a given weight of raw material. The quantity of waste removed during the various phases of yarn spinning, such as blow-room, carding, and combing, is often used to determine yarn realisation. Yarn realisation ranges between 85% and 90% in carded cotton yarns and between 67% and 75% in combed cotton yarns. Significance Yarn realisation is one of the important factors that affect the quality of the yarn, profitability, and lead time of a spinning mill. Better realisations make spinning mills more competitive, and greater realisations mean better economics for a spinning business. Even minor changes in yarn realisation, say 1%, translate into a huge impact on spinning production economics. Thus, controlling yarn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses (referred to as "weights"). Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue. Etymology The word yarn comes from Middle English, from the Old English ''gearn'', akin to Old High German ''garn'', "yarn," Dutch "garen," Italian ''chordē'', "string," and Sanskrit ''hira'', "band." History The human production of yarn is known to have existed since the Stone Age and earlier prehistory, with ancient ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

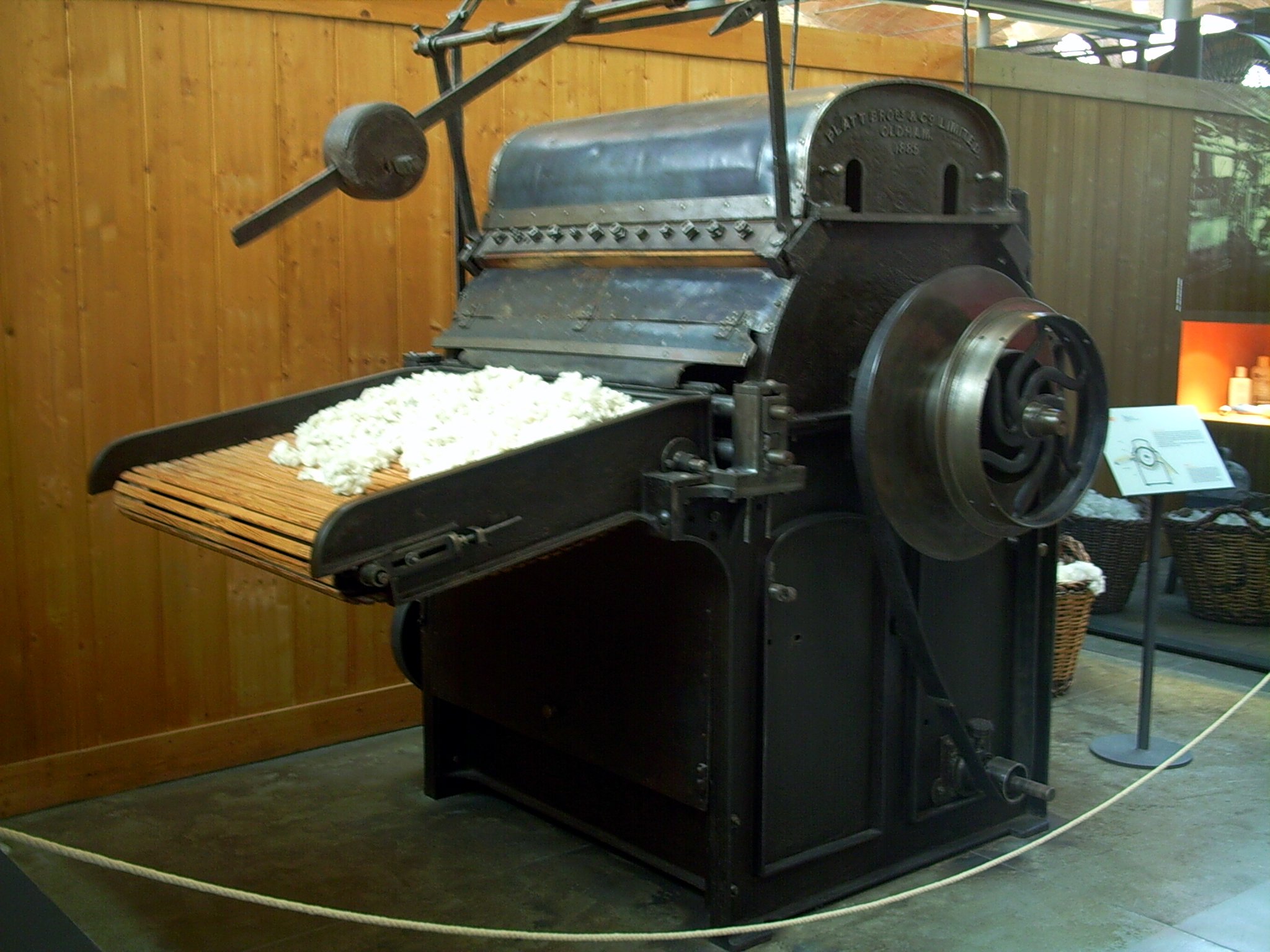

Carding

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing. The word is derived from the Latin meaning thistle or teasel, as dried vegetable teasels were first used to comb the raw wool before technological advances led to the use of machines. Overview These ordered fibres can then be passed on to other processes that are specific to the desired end use of the fibre: Cotton, batting, felt, woollen or worsted yarn, etc. Carding can also be used to create blends of different fibres or different colours. When blending, the c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combing

Combing is a method for preparing carded fibre for spinning. Combing is divided into linear and circular combing. The Noble comb is an example of circular combing. The French comb is an example of linear combing. The process of combing is accompanied by ''gilling'', a process of evening out carded or combed top making it suitable for spinning. Combing separates out short fibres by means of a rotating ring or rectilinear row of steel pins. The fibres in the ' top' it produces have been straightened and lie parallel to each other. When combing wool, the discarded short fibres are called noils, and are ground up into shoddy. In general, there are two main systems of preparing fibre for yarn: the worsted system and the woollen system. The worsted system is defined by the removal of short fibres by combing and top preparation by gilling. In the woollen system, short fibres are retained, and it may or may not involve combing. Description The circular combs used have long metal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinning (textiles)

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose (the most common form of rayon), and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution. Process The yarn issuing from the drafting rollers passes through a thread-guide, round a traveller that is free to rotate around a ring, and then onto a tube or bobbin, which is carried on to a spindle, the axis of which passes through a center of the ring. The spindle is driven (usually at an angular ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ginning

A cotton gin—meaning "cotton engine"—is a machine that quickly and easily separates cotton fibers from their seeds, enabling much greater productivity than manual cotton separation.. Reprinted by McGraw-Hill, New York and London, 1926 (); and by Lindsay Publications, Inc., Bradley, Illinois, (). The fibers are then processed into various cotton goods such as calico, while any undamaged cotton is used largely for textiles like clothing. The separated seeds may be used to grow more cotton or to produce cottonseed oil. Handheld roller gins had been used in the Indian subcontinent since at earliest AD 500 and then in other regions. The Indian worm-gear roller gin, invented sometime around the 16th century, has, according to Lakwete, remained virtually unchanged up to the present time. A modern mechanical cotton gin was created by American inventor Eli Whitney in 1793 and patented in 1794. Whitney's gin used a combination of a wire screen and small wire hooks to pull the cott ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cotton

Cotton is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus '' Gossypium'' in the mallow family Malvaceae. The fiber is almost pure cellulose, and can contain minor percentages of waxes, fats, pectins, and water. Under natural conditions, the cotton bolls will increase the dispersal of the seeds. The plant is a shrub native to tropical and subtropical regions around the world, including the Americas, Africa, Egypt and India. The greatest diversity of wild cotton species is found in Mexico, followed by Australia and Africa. Cotton was independently domesticated in the Old and New Worlds. The fiber is most often spun into yarn or thread and used to make a soft, breathable, and durable textile. The use of cotton for fabric is known to date to prehistoric times; fragments of cotton fabric dated to the fifth millennium BC have been found in the Indus Valley civilization, as well as fabric remnants date ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile Manufacturing

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiber

Fiber or fibre (from la, fibra, links=no) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorporate fibers, for example carbon fiber and ultra-high-molecular-weight polyethylene. Synthetic fibers can often be produced very cheaply and in large amounts compared to natural fibers, but for clothing natural fibers can give some benefits, such as comfort, over their synthetic counterparts. Natural fibers Natural fibers develop or occur in the fiber shape, and include those produced by plants, animals, and geological processes. They can be classified according to their origin: * Vegetable fibers are generally based on arrangements of cellulose, often with lignin: examples include cotton, hemp, jute, flax, abaca, piña, ramie, sisal, bagasse, and banana. Plant fibers are employed in the manufacture of paper and textile (cloth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cotton Bale

A Cotton bale is a standard-sized and weighted pack of compressed cotton lint after ginning. The dimensions and weight may vary with different cotton-producing countries. Significance A bale has an essential role from the farm to the factory. The cotton yield is calculated in terms of the number of bales. Bale is a standard packaging method for cotton to avoid various hassles in handling, packing, and transportation. The bales also protect the lint from foreign contamination and make them readily identifiable. Standards Bale A "bale of cotton" is also the standard trading unit for cotton on the wholesale national and international markets. Although different cotton-growing countries have their bale standards, for example, In the United States, cotton is usually measured at approximately 0.48 cubic meters (17 cubic feet) and weighs 226.8 kilograms (500 pounds). In India, the standard bale size is 170 kg. Parameters The most important parameters of a cotton bale ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blend (textile)

A blend is a mixture of two or more fibers. In yarn spinning, different compositions, lengths, diameters, or colors may be combined to create a blend. Blended textiles are fabrics or yarns produced with a combination of two or more types of different fibers, or yarns to obtain desired traits and aesthetics. Blending is possible at various stages of textile manufacturing. The term, ''blend'', refers to spun fibers or a fabric composed of such fibers. There are several synonymous terms: a combination yarn is made up of two strands of different fibers twisted together to form a ply; a mixture or mixed cloth refers to blended cloths in which different types of yarns are used in warp and weft sides. Union or union fabric was a 19th century term for a blended fabric. It is no longer used. History Blending in textiles is an old practice which became more widespread after around 1980. Recognizing the growing popularity of blends, the Wool Bureau introduced the "Wool blend" mark in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Staple (textiles)

A staple fiber is a textile fiber of discrete length. The opposite is a filament fiber, which comes in continuous lengths. Staple length is a characteristic fiber length of a sample of staple fibers. It is an essential criterion in yarn spinning aids in cohesion and twisting. Compared to synthetic fibers, natural fibers tend to have different and shorter lengths. The quality of natural fibers like cotton is categorized on staple length such as short, medium, long-staple and, extra long. Gossypium barbadense, one of several cotton species, produces extra-long staple fibers. The staple fibers may be obtained from natural and synthetic sources. In the case of synthetics and blends, the filament yarns are cut to a predetermined length (staple length). ''The filament is <1 mm in maximum cross section (i.e., diameter, in most cases). A filament can be compared ... Manufactured fibers are produced either as continuous infinite length filaments or cut staple of desired length value. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |