|

Variable Pitch Fan

A variable pitch fan is similar in concept to that of a variable-pitch propeller and involves progressively reducing the pitch (or blade angle) of the fan on a turbofan as the engine is throttled. Although variable pitch fans are used in some industrial applications, the focus of this article is on their use in turbofan engines. No production engine uses such a feature; however, it will likely be required on at least some of the next generation of high bypass ratio turbofans. One of the methods used to reduce thrust-specific fuel consumption is to improve propulsive efficiency. This involves reducing the effective jet velocity of the engine by reducing specific thrust. This, in turn, reduces the optimum fan pressure ratio required and consequently the cold nozzle pressure ratio. At cruise flight speeds, the nozzle is choked and the fan working line is fairly steep and linear. However, at low flight speeds, the ram pressure rise in the air intake is so low the nozzle is well un- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Turbofan

A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft engine, aircraft propulsion. The word "turbofan" is a combination of references to the preceding generation engine technology of the turbojet and the additional fan stage. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust. The ratio of the mass-flow of air bypassing the engine core to the mass-flow of air passing through the core is referred to as the bypass ratio. The engine produces thrust through a combination of these two portions working together. Engines that use more Propel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Bypass Ratio

The bypass ratio (BPR) of a turbofan engine is the ratio between the mass flow rate of the bypass stream to the mass flow rate entering the core. A 10:1 bypass ratio, for example, means that 10 kg of air passes through the bypass duct for every 1 kg of air passing through the core. Turbofan engines are usually described in terms of BPR, which together with engine pressure ratio, turbine inlet temperature and fan pressure ratio are important design parameters. In addition, BPR is quoted for turboprop and unducted fan installations because their high propulsive efficiency gives them the overall efficiency characteristics of very high bypass turbofans. This allows them to be shown together with turbofans on plots which show trends of reducing specific fuel consumption (SFC) with increasing BPR. BPR is also quoted for lift fan installations where the fan airflow is remote from the engine and doesn't physically touch the engine core. Bypass provides a lower fuel consumption ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Thrust-specific Fuel Consumption

Thrust-specific fuel consumption (TSFC) is the fuel efficiency of an engine design with respect to thrust output. TSFC may also be thought of as fuel consumption (grams/second) per unit of thrust (newtons, or N), hence ''thrust-specific''. This figure is inversely proportional to specific impulse, which is the amount of thrust produced per unit fuel consumed. TSFC or SFC for thrust engines (e.g. turbojets, turbofans, ramjets, rockets, etc.) is the mass of fuel needed to provide the net thrust for a given period e.g. lb/(h·lbf) (pounds of fuel per hour-pound of thrust) or g/(s·kN) (grams of fuel per second-kilonewton). Mass of fuel is used, rather than volume (gallons or litres) for the fuel measure, since it is independent of temperature. Specific fuel consumption of air-breathing jet engines at their maximum efficiency is more or less proportional to exhaust speed. The fuel consumption ''per mile'' or ''per kilometre'' is a more appropriate comparison for aircraft that travel a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

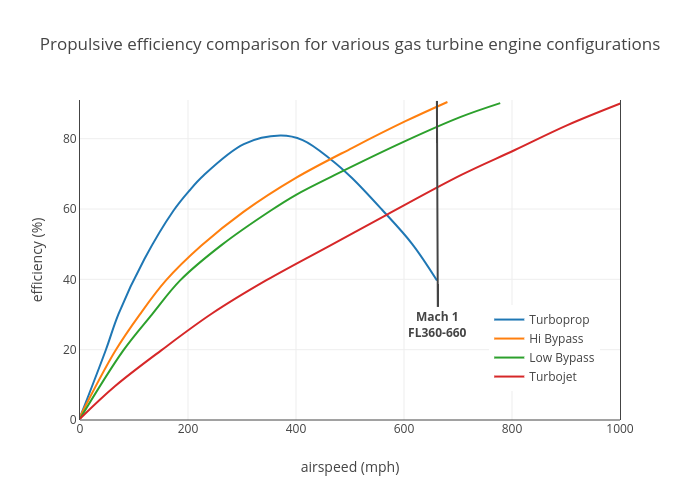

Propulsive Efficiency

In aerospace engineering, concerning aircraft, rocket and spacecraft design, overall propulsion system efficiency \eta is the efficiency with which the energy contained in a vehicle's fuel is converted into kinetic energy of the vehicle, to accelerate it, or to replace losses due to aerodynamic drag or gravity. Mathematically, it is represented as \eta = \eta_\mathrm \eta_\mathrm, where \eta_\mathrm is the cycle efficiency and \eta_\mathrm is the propulsive efficiency. The cycle efficiency is expressed as the percentage of the heat energy in the fuel that is converted to mechanical energy in the engine, and the propulsive efficiency is expressed as the proportion of the mechanical energy actually used to propel the aircraft. The propulsive efficiency is always less than one, because conservation of momentum requires that the exhaust have some of the kinetic energy, and the propulsive mechanism (whether propeller, jet exhaust, or ducted fan) is never perfectly efficient. It is great ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Cruise (aeronautics)

Cruise is the phase of aircraft flight from when the aircraft levels off after a climb until it begins to descend for landing. Cruising usually comprises the majority of a flight, and may include small changes in heading (direction of flight), airspeed, and altitude. Airliner cruise Commercial or passenger aircraft are usually designed for optimum performance around their cruise speed ( VC) and cruise altitude. Factors affecting optimum cruise speed and altitude include payload, center of gravity, air temperature, and humidity. Cruise altitude is usually where the higher ground speed is balanced against the decrease in engine thrust and efficiency at higher altitudes. Common narrowbodies like the Airbus A320 and Boeing 737NG cruise at , while modern widebodies like the Airbus A350 and Boeing 787 cruise at . The typical cruising altitude for commercial airliners is . The speed which covers the greatest distance for a given amount of fuel is known as the maximum range spe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Ram Pressure

Ram pressure is a pressure exerted on a body moving through a fluid medium, caused by relative bulk motion of the fluid rather than random thermal motion. It causes a drag (physics), drag force to be exerted on the body. Ram pressure is given in tensor form as :P_\text= \rho u_i u_j, where \rho is the density of the fluid; P_\text is the momentum flux per second in the i direction through a surface with normal in the j direction. u_i,u_j are the components of the fluid velocity in these directions. The total Cauchy stress tensor \sigma_ is the sum of this ram pressure and the isotropic thermal pressure (in the absence of viscosity). In the simple case when the relative velocity is normal to the surface, and momentum is fully transferred to the object, the ram pressure becomes :P_\text = 1/2 \rho u^2. Derivation The Lagrangian and Eulerian specification of the flow field, Eulerian form of the Cauchy momentum equation for a fluid is :\rho\frac = -\vec \nabla p - \rho(\vec u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Compressor Map

A compressor map is a chart which shows the performance of a turbomachinery gas compressor, compressor. This type of compressor is used in gas turbine engines, for supercharging reciprocating engines and for industrial processes, where it is known as a dynamic compressor. A map is created from compressor rig test results or predicted by a special computer program. Alternatively the map of a similar compressor can be suitably scaled. This article is an overview of compressor maps and their different applications and also has detailed explanations of maps for a fan and intermediate and high-pressure compressors from a three-shaft aero-engine as specific examples. Compressor maps are an integral part of predicting the performance of gas turbine and turbocharged engines, both at design and off-design conditions. They also serve a critical purpose in selecting the correct compressors for industrial processes. Fans and turbines also have operating maps, although the latter are significan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Overall Pressure Ratio

In aeronautical engineering, overall pressure ratio, or overall compression ratio, is the amount of times the pressure increases due to ram compression and the work done by the compressor stages. The compressor pressure ratio is the ratio of the stagnation pressures at the front and rear of the compressor of a gas turbine. Overall pressure ratio in a high-bypass turbofan is a function of inlet pressure ratio and compressor pressure ratio: OPR = IPR \times CPR The terms ''compression ratio'' and ''pressure ratio'' are used interchangeably. Advantages of high overall pressure ratios As can be seen in the formula for maximum theoretical thermal efficiency in an ideal Brayton cycle engine, a high pressure ratio leads to higher thermal efficiency: \eta = 1-\left(\frac\right) where PR is the pressure ratio and gamma the heat capacity ratio of the fluid, 1.4 for air. Keep in mind that pressure ratio scales exponentially with the number of compressor stages. Imagine a gas turbin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Turbomeca Astafan

The Turbomeca Astafan is a single-spool, variable-pitch turbofan engine developed from the Turbomeca Astazou. Despite successful flight-testing, an efficient, quiet and clean design (compared to turbojets and conventional turbofans) and some commercial interest, the Astafan never entered series production. The engines were only flown on the Fouga 90 prototype and Turbomeca's two test aircraft. Design The engine combines an Astazou-derived centrifugal compressor with up to three axial compressor stages (depending on the version of the engine), driven by a common driveshaft. The fan section is composed of a unique variable pitch fan and fixed stator blades mounted at the front of the engine. Blade pitch is varied by a hydraulic piston mounted in the fan hub, while the fan itself is powered via a reduction gear from the main driveshaft. The engine is designed to operate at a constant speed, no matter the thrust output—a characteristic permitted by the Astafan's use of precise fue ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Reduction Gearbox

An epicyclic gear train (also known as a planetary gearset) is a gear reduction assembly consisting of two gears mounted so that the center of one gear (the "planet") revolves around the center of the other (the "sun"). A carrier connects the centers of the two gears and rotates, to carry the planet gear(s) around the sun gear. The planet and sun gears mesh so that their pitch circles roll without slip. If the sun gear is held fixed, then a point on the pitch circle of the planet gear traces an epicycloid curve. An epicyclic gear train can be assembled so the planet gear rolls on the inside of the pitch circle of an outer gear ring, or ring gear, sometimes called an ''annulus gear''. Such an assembly of a planet engaging both a sun gear and a ring gear is called a planetary gear train.J. J. Uicker, G. R. Pennock and J. E. Shigley, 2003, ''Theory of Machines and Mechanisms,'' Oxford University Press, New York.B. Paul, 1979, ''Kinematics and Dynamics of Planar Machinery'', Prenti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Ultrafan

The Rolls-Royce Trent is a family of high-bypass turbofans produced by Rolls-Royce. It continues the three spool architecture of the RB211 with a maximum thrust ranging from . Launched as the RB-211-524L in June 1988, the prototype first ran in August 1990. Its first variant is the Trent 700 introduced on the Airbus A330 in March 1995, then the Trent 800 for the Boeing 777 (1996), the Trent 500 for the A340 (2002), the Trent 900 for the A380 (2007), the Trent 1000 for the Boeing 787 (2011), the Trent XWB for the A350 (2015), and the Trent 7000 for the A330neo (2018). It also has marine and industrial variants such as the RR MT30. Development Despite the success of the RB211, Rolls-Royce's share of the large civil turbofan market was only 8% when it was privatised in April 1987, the market being dominated by General Electric and Pratt & Whitney. In June 1987, Rolls-Royce was studying whether to launch a thrust variant of the RB211, to be called the RB211-700, for the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |