|

Underreamer

An underreamer is a device used to enlarge the borehole below an existing casing or restriction, during a well drilling operation. It can be positioned either above the drill bit or above a pilot assembly run inside the existing borehole. Numerous designs exist, in sizes varying from a couple of inches to above 40". It is typically used in hydrocarbon drilling operations, but also geothermal or water wells drilling. This device is typically composed of a body connected to the drillstring, and of mobile parts ("arms" , "blocks" or "blades", typically 3 of them) retracted in the body during the descent and extended downhole for the reaming operation. Reaming itself can be conducted either in an existing borehole ("pilot reaming") or during the drilling operation ("reaming while drilling"). Underreaming is primarily used to allow a wider clearance for running and cementing the casing correctly, either due to restrictions (swelling shales, tortuosity) or to be able to run a larger ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Borehole

A borehole is a narrow shaft bored in the ground, either vertically or horizontally. A borehole may be constructed for many different purposes, including the extraction of water ( drilled water well and tube well), other liquids (such as petroleum), or gases (such as natural gas). It may also be part of a geotechnical investigation, environmental site assessment, mineral exploration, temperature measurement, as a pilot hole for installing piers or underground utilities, for geothermal installations, or for underground storage of unwanted substances, e.g. in carbon capture and storage. Importance Engineers and environmental consultants use the term ''borehole'' to collectively describe all of the various types of holes drilled as part of a geotechnical investigation or environmental site assessment (a so-called Phase II ESA). This includes holes advanced to collect soil samples, water samples or rock cores, to advance ''in situ'' sampling equipment, or to install monitoring ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Well Drilling

Well drilling is the process of drilling a hole in the ground for the extraction of a natural resource such as ground water, brine, natural gas, or petroleum, for the injection of a fluid from surface to a subsurface reservoir or for subsurface formations evaluation or monitoring. Drilling for the exploration of the nature of the material underground (for instance in search of metallic ore) is best described as ''borehole'' drilling. The earliest wells were water wells, shallow pits dug by hand in regions where the water table approached the surface, usually with masonry or wooden walls lining the interior to prevent collapse. Modern drilling techniques utilize long drill shafts, producing holes much narrower and deeper than could be produced by digging. Well drilling can be done either manually or mechanically and the nature of required equipment varies from extremely simple and cheap to very sophisticated. Managed Pressure Drilling (MPD) is defined by the International A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spindle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casing (borehole)

Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream. The lower portion (and sometimes the entirety) is typically held in place with cement. Deeper strings usually are not cemented all the way to the surface, so the weight of the pipe must be partially supported by a casing hanger in the wellhead. Casing that is cemented in place aids the drilling process in several ways: * Prevents contamination of fresh water well zones. * Prevents unstable upper formations from caving in and sticking the drill string or forming large caverns. * Provides a strong upper foundation to allow use of high-density drilling fluid to continue drilling deeper. * Isolates various zones, which may have different pressures or fluids, in the drilled formations from one another. * Seals off high pressure zones ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Offshore Drilling

Offshore drilling is a mechanical process where a wellbore is drilled below the seabed. It is typically carried out in order to explore for and subsequently extract petroleum that lies in rock formations beneath the seabed. Most commonly, the term is used to describe drilling activities on the continental shelf, though the term can also be applied to drilling in lakes, inshore waters and inland seas. Offshore drilling presents environmental challenges, both offshore and onshore from the produced hydrocarbons and the materials used during the drilling operation. Controversies include the ongoing US offshore drilling debate. There are many different types of facilities from which offshore drilling operations take place. These include bottom founded drilling rigs ( jackup barges and swamp barges), combined drilling and production facilities either bottom founded or floating platforms, and deepwater mobile offshore drilling units (MODU) including semi-submersibles or drillships. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrocarbon Exploration

Hydrocarbon exploration (or oil and gas exploration) is the search by petroleum geologists and geophysicists for deposits of hydrocarbons, particularly petroleum and natural gas, in the Earth using petroleum geology. Exploration methods Visible surface features such as oil seeps, natural gas seeps, pockmarks (underwater craters caused by escaping gas) provide basic evidence of hydrocarbon generation (be it shallow or deep in the Earth). However, most exploration depends on highly sophisticated technology to detect and determine the extent of these deposits using exploration geophysics. Areas thought to contain hydrocarbons are initially subjected to a gravity survey, magnetic survey, passive seismic or regional seismic reflection surveys to detect large-scale features of the sub-surface geology. Features of interest (known as ''leads'') are subjected to more detailed seismic surveys which work on the principle of the time it takes for reflected sound waves to travel throu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extended Reach Drilling

Extended Reach Drilling (ERD) is directional drilling of very long horizontal wells. The aims of ERD are: a) to reach a larger area from one surface drilling location, and b) to keep a well in a reservoir for a longer distance in order to maximize its productivity and drainage capability. Today's challenges in ERD are hole cleaning, managing the mechanical loads on the drill string and managing downhole pressure. There is also the cost issue to consider. Definition Early ERD-well definitions related wells to those that exceeded some step-out/vertical-depth ratio (often 2:1). However, for most highly deviated wells in deepwater environments, this definition clearly does not fit. Some methods have evolved to categorize wells according to their stepout within different vertical-depth ranges. ERD wells then can be described conveniently as shallow, intermediate, deep, and ultradeep. Other variants are associated with operating in deep water and high-pressure/high-temperature environm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

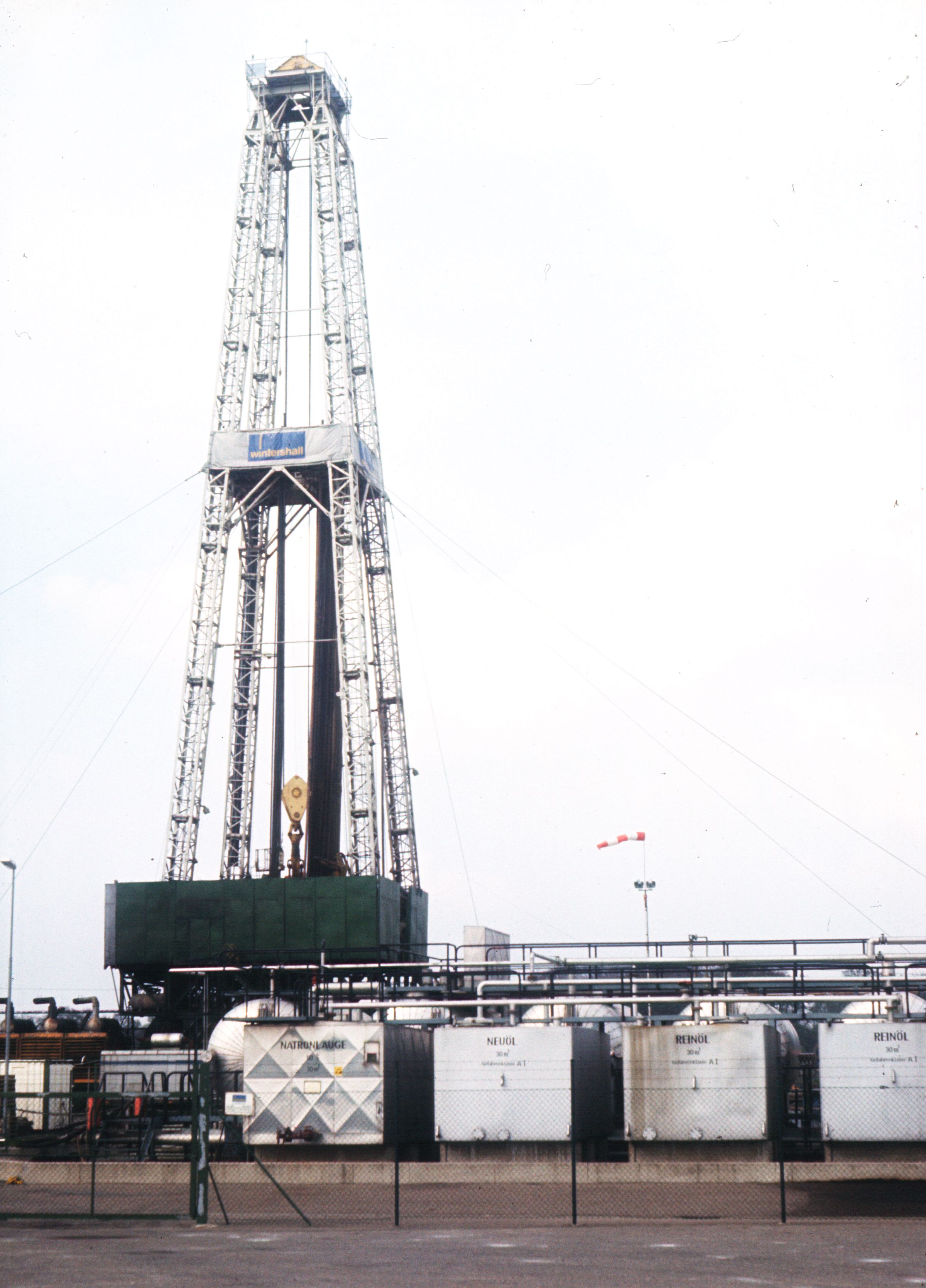

Drilling Rig

A drilling rig is an integrated system that drills wells, such as oil or water wells, or holes for piling and other construction purposes, into the earth's subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called 'offshore oil rigs' even if they don't contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth's crust. Small to medi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Driller (oil)

The Driller is a team leader in charge during the process of well drilling. The term is commonly used in the context of an oil well drilling rig. Driller comes after the Toolpusher in the Rig crew hierarchy. Toolpusher takes the operation orders from the Company-man. Toolpusher then supervises these order to the driller and the rest of the drilling crew and gets the job done. While Toolpusher, driller and the drilling crew generally belong to the Drilling contractor company, Company-man is the employee of the operator company. The driller is in charge of the crew, and running the rig itself. Most of the time, his or her job is simply to monitor the rig's activity, while the automatic driller runs the breaks and drills the hole. The driller is responsible for interpreting the signals the well gives regarding gas and fluids with high pressure. In an emergency he is also responsible for taking the correct counter measures to stop an uncontrolled well control situation from emerging. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hole Opener

A hole opener is a device used to enlarge the borehole during a well drilling operation. It can be positioned either above the drill bit or above a pilot run inside the existing borehole. Usages range from hydrocarbon drilling operations to water drilling or horizontal drilling. Hole openers are also used when a hole must be logged, since logging tools generally cannot handle holes larger than 17 and a half inches in diameter. Hole opener arms have to sustain heavy loads during operations and are generally made of high-grade alloy steel, welded onto a solid alloy steel body. Some designs feature replaceable arms, allowing for size changes but decreasing overall robustness. Numerous designs exist, in sizes varying from a couple of inches to above 50". They can have rolling cutters or drag blades, and can be used for either direct or reverse circulation applications. See also * Casing cutter *Drilling rig *Driller (oil) * Drag bit *Drill bit *Drilling stabilizer {{Short descript ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)