|

Tube Drawing

Tube drawing is a process to size a tube by shrinking a large diameter tube into a smaller one, by drawing the tube through a die. This process produces high-quality tubing with precise dimensions, good surface finish, and the added strength of cold working.Degarmo, p. 433. For this reason this process is established for many materials, mainly metalworking but also glass. Because it is so versatile, tube drawing is suitable for both large- and small-scale production. The large-scale production of glass typically uses a one step process where glass is directly drawn into a tube from a melting tank. There are five types of tube drawing: tube sinking, mandrel drawing, stationary mandrel, moving mandrel, and floating mandrel. A mandrel is used in many of the types to prevent buckling or wrinkling in the workpiece. Processes Tube sinking Tube sinking, also known as ''free tube drawing'', reduces the diameter of the tube without a mandrel inside the tube. The inner diameter is determine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drawing (manufacturing)

Drawing is a metalworking process that uses tensile forces to stretch (elongate) metal, glass, or plastic. As the metal is drawn (pulled), it stretches to become thinner, to achieve a desired shape and thickness. Drawing is classified into two types: sheet metal drawing and wire, bar, and tube drawing. Sheet metal drawing is defined as a plastic deformation over a curved axis. For wire, bar, and tube drawing, the starting stock is drawn through a die to reduce its diameter and increase its length. Drawing is usually performed at room temperature, thus classified as a cold working process; however, drawing may also be performed at elevated temperatures to hot work large wires, rods or hollow sections in order to reduce forces.Degarmo, p. 432.Kalpakjian, pp. 415–419. Drawing differs from rolling in that the pressure of drawing is not transmitted through the turning action of the mill but instead depends on force applied locally near the area of compression. This means the amoun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a press. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Working

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal harder, stiffer, and stronger, but less plastic, and may cause cracks of the piece. The possible uses of cold forming are extremely v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda–lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term ''glass'', in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based glass that they are simply called by the name of the material. Despite bei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass Tube

Glass tubes are mainly cylindrical hollow-wares. Their special shape combined with the huge variety of glass types (like borosilicate, flint, aluminosilicate, soda lime, lead or quartz glass), allows the use of glass tubing in many applications. For example, laboratory glassware, lighting applications, solar thermal systems and pharmaceutical packaging to name the largest. In the past, scientists constructed their own laboratory apparatus prior to the ubiquity of interchangeable ground glass joints. Today, commercially available parts connected by ground glass joints are preferred; where specialized glassware are required, they are made to measure using commercially available glass tubes by specialist glassblowers. For example, a Schlenk line is made of two large glass tubes, connected by stopcocks and smaller glass tubes, which are further connected to plastic hoses. Industrial Relevance Compared to other materials like plastics the importance of cylindrical half-finished produ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Finish

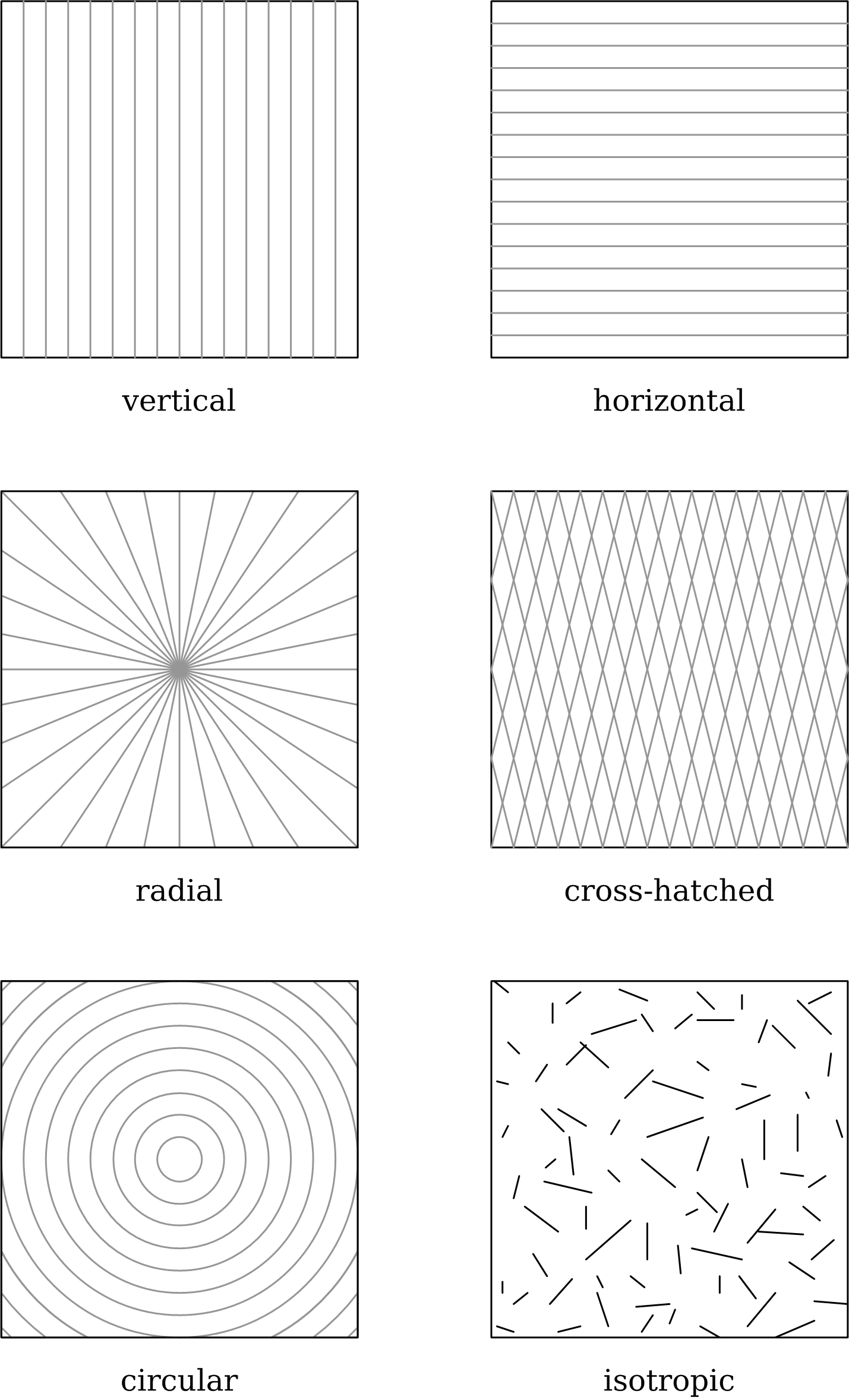

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polishing, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Trombone

The trombone (german: Posaune, Italian, French: ''trombone'') is a musical instrument in the Brass instrument, brass family. As with all brass instruments, sound is produced when the player's vibrating lips cause the Standing wave, air column inside the instrument to vibrate. Nearly all trombones use a telescoping slide mechanism to alter the Pitch (music), pitch instead of the brass instrument valve, valves used by other brass instruments. The valve trombone is an exception, using three valves similar to those on a trumpet, and the superbone has valves and a slide. The word "trombone" derives from Italian ''tromba'' (trumpet) and ''-one'' (a suffix meaning "large"), so the name means "large trumpet". The trombone has a predominantly cylindrical bore like the trumpet, in contrast to the more conical brass instruments like the cornet, the euphonium, and the French horn. The most frequently encountered trombones are the tenor trombone and bass trombone. These are treated as trans ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Handslides

The trombone (german: Posaune, Italian, French: ''trombone'') is a musical instrument in the brass family. As with all brass instruments, sound is produced when the player's vibrating lips cause the air column inside the instrument to vibrate. Nearly all trombones use a telescoping slide mechanism to alter the pitch instead of the valves used by other brass instruments. The valve trombone is an exception, using three valves similar to those on a trumpet, and the superbone has valves and a slide. The word "trombone" derives from Italian ''tromba'' (trumpet) and ''-one'' (a suffix meaning "large"), so the name means "large trumpet". The trombone has a predominantly cylindrical bore like the trumpet, in contrast to the more conical brass instruments like the cornet, the euphonium, and the French horn. The most frequently encountered trombones are the tenor trombone and bass trombone. These are treated as non-transposing instruments, reading at concert pitch in bass clef, with h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Getzen

The Getzen Company is a family-owned manufacturer and wholesaler of brass instruments. The present product portfolio consists of trumpets, cornets, flugelhorns, trombones, and a baritone horn. Four generations of the Getzen family have participated in the company. Most Getzen instruments are rated well by consumers, and it is well known for its custom line of Edwards trumpets and trombones. History Founding In 1939, Anthony James (T.J.) Getzen founded the Getzen Company, in Elkhorn, Wisconsin. Getzen had trained in instrument repair with the C.G. Conn company and worked as a plant superintendent for the Frank Holton Company. Initially opened as a repair shop, the company expanded after World War II to instrument manufacture. In 1946, Getzen produced its first trombones. In 1947, Getzen started producing trumpets and cornets as well. In 1949, J. Robert Getzen, T.J.'s son, assumed the position of plant superintendent, and Getzen started to produce piston bugles. These bugles be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipe And Tube Bender

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a die. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry. Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubricants ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |