|

Tribometer

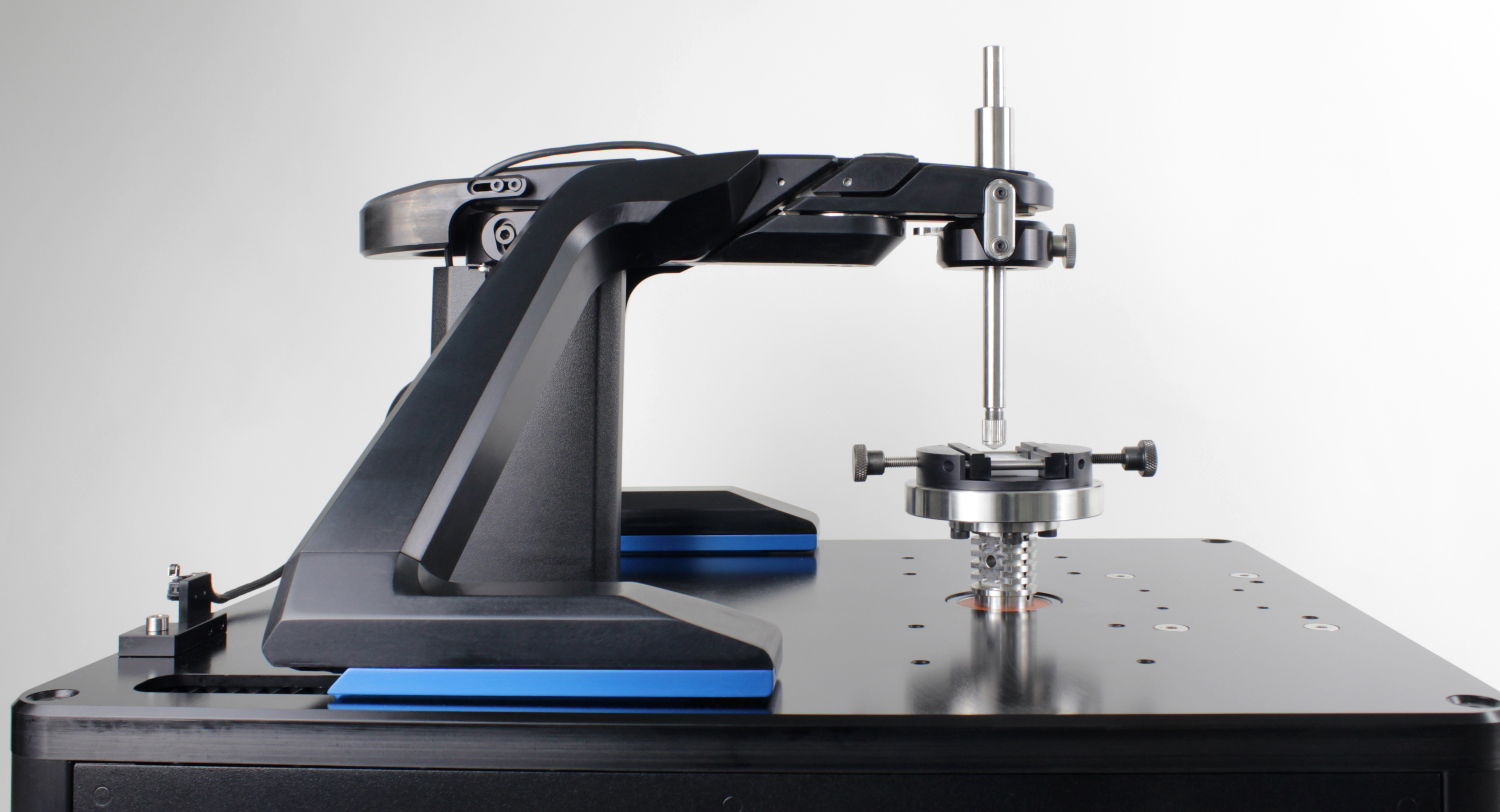

A tribometer is an instrument that measures Tribology, tribological quantities, such as coefficient of friction, friction force, and wear volume, between two surfaces in contact. It was invented by the 18th century Netherlands, Dutch scientist Pieter van Musschenbroek, Musschenbroek A tribotester is the general name given to a machine or device used to perform tests and simulations of wear, friction and lubrication which are the subject of the study of tribology. Often tribotesters are extremely specific in their function and are fabricated by manufacturers who desire to test and analyze the long-term performance of their products. An example is that of Implant (medicine), orthopedic implant manufacturers who have spent considerable sums of money to develop tribotesters that accurately reproduce the motions and forces that occur in human hip joints so that they can perform accelerated wear tests of their products. Theory A simple tribometer is described by a hanging mass and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tribology

Tribology is the science and engineering of interacting surfaces in relative Motion (physics), motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. People who work in the field of tribology are referred to as ''tribologists''. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. In lubricated tribosystems, contact stress can create tribofilms. Subfields of tribology include biotribology, nanotribology, space tribology and tribotronics. Etymology The word ''tribology'' derives from the Ancient Greek, Greek root τριβ- of the verb , ''wiktionary:tribo-, tribo'', "I rub" in classic Greek, and the suffix ''-logy'' from , ''wiktionary:-logia, -logia'' "study of", "knowledge of". Peter Jost coined the word in 1966, in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coefficient Of Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction: *Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into ''static friction'' ("stiction") between non-moving surfaces, and ''kinetic friction'' between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as asperities (see Figure 1). *Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other. *Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces. *Skin friction is a component of drag, the force resisting the motion of a fluid across the surface of a body. *Internal friction is the force resisting motion between the elements making up a s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bouncing Ball

The physics of a bouncing ball concerns the physical behaviour of bouncing balls, particularly its motion before, during, and after impact against the surface of another body. Several aspects of a bouncing ball's behaviour serve as an introduction to mechanics in high school or undergraduate level physics courses. However, the exact modelling of the behaviour is complex and of interest in sports engineering. The motion of a ball is generally described by projectile motion (which can be affected by gravity, drag, the Magnus effect, and buoyancy), while its impact is usually characterized through the coefficient of restitution (which can be affected by the nature of the ball, the nature of the impacting surface, the impact velocity, rotation, and local conditions such as temperature and pressure). To ensure fair play, many sports governing bodies set limits on the bounciness of their ball and forbid tampering with the ball's aerodynamic properties. The bounciness of balls has ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Twist Compression Tester

The Twist Compression Tester ("TCT") is a hydraulically operated bench-top apparatus used to evaluate the level of friction and/or wear between two materials under lubricated or non-lubricated conditions. Under controlled conditions, a rotating annular specimen is brought into contact with a non-rotating flat specimen. Specimens can be prepared from die materials, sheet or plate materials, metals or plastics. The applied normal force and the torque are measured, and the coefficient of friction is calculated. Although the twist-compression test does not simulate an actual process, it has been demonstrated to correlate well with processes where boundary lubrication predominates and lubricant depletion occurs. The Twist Compression Tester is an invaluable diagnostic tool for: evaluating lubricants, materials and coatings; screening products for production; understanding the effect of additives in a lubricant; and many other value-added testing scenarios.Investigation of galli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasion (mechanical)

Abrasion is the process of scuffing, scratching, wearing down, marring, or rubbing away. It can be intentionally imposed in a controlled process using an abrasive. Abrasion can be an undesirable effect of exposure to normal use or exposure to the elements. In stone shaping Ancient artists, working in stone, used abrasion to create sculptures. The artist selected dense stones like carbonite and emery and rubbed them consistently against comparatively softer stones like limestone and granite. The artist used different sizes and shapes of abrasives, or turned them in various ways as they rubbed, to create effects on the softer stone's surface. Water was continuously poured over the surface to carry away particles. Abrasive technique in stone shaping was a long, tedious process that, with patience, resulted in eternal works of art in stone. Models The Archard equation is a simple model used to describe sliding wear and is based on the theory of asperity contact. Q = \frac H whe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Train

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond-like Carbon

Diamond-like carbon (DLC) is a class of amorphous carbon material that displays some of the typical properties of diamond. DLC is usually applied as coatings to other materials that could benefit from such properties. DLC exists in seven different forms. All seven contain significant amounts of sp3 hybridized carbon atoms. The reason that there are different types is that even diamond can be found in two crystalline polytypes. The more common one uses a cubic lattice, while the less common one, lonsdaleite, has a hexagonal lattice. By mixing these polytypes at the nanoscale, DLC coatings can be made that at the same time are amorphous, flexible, and yet purely sp3 bonded "diamond". The hardest, strongest, and slickest is tetrahedral amorphous carbon (ta-C). Ta-C can be considered to be the "pure" form of DLC, since it consists almost entirely of sp3 bonded carbon atoms. Fillers such as hydrogen, graphitic sp2 carbon, and metals are used in the other 6 forms to reduce productio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coatings

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Coatings may be applied as liquids, gases or solids e.g. Powder coatings. Paints and lacquers are coatings that mostly have dual uses of protecting the substrate and being decorative, although some artists paints are only for decoration, and the paint on large industrial pipes is for preventing corrosion and identification e.g. blue for process water, red for fire-fighting control etc. Functional coatings may be applied to change the surface properties of the substrate, such as adhesion, wettability, corrosion resistance, or wear resistance. In other cases, e.g. semiconductor device fabrication (where the substrate is a wafer), the coating adds a completely new property, such as a magnetic response or electrical conductivity, and forms an essential part of the finished product. A major consideratio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gears

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a '' transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Bearings

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races. History Although bearings had been developed since ancient times, the first mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |