|

Tolerance Analysis

Tolerance analysis is the general term for activities related to the study of accumulated variation in mechanical parts and assemblies. Its methods may be used on other types of systems subject to accumulated variation, such as mechanical and electrical systems. Engineers analyze tolerances for the purpose of evaluating geometric dimensioning and tolerancing (GD&T). Methods include 2D tolerance stacks, 3D Monte Carlo simulations, and datum conversions. Tolerance stackups or tolerance stacks are used to describe the problem-solving process in mechanical engineering of calculating the effects of the accumulated variation that is allowed by specified dimensions and tolerances. Typically these dimensions and tolerances are specified on an engineering drawing. Arithmetic tolerance stackups use the worst-case maximum or minimum values of dimensions and tolerances to calculate the maximum and minimum distance (clearance or interference) between two features or parts. Statistical toler ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geometric Dimensioning And Tolerancing

Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances and relationships. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describe nominal geometry and its allowable variation. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part. GD&T is used to define the nominal (theoretically perfect) geometry of parts and assemblies, to define the allowable variation in form and possible size of individual features, and to define the allowable variation between features. *Dimensioning specifications define the nominal, as-modeled or as-intended geometry. One example is a basic dimension. *Tolerancing specifications define the allowable variation for the form and possibly the size of individual features, and the allowable variation in orientation and location between features. Two exam ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Monte Carlo Simulation

Monte Carlo methods, or Monte Carlo experiments, are a broad class of computational algorithms that rely on repeated random sampling to obtain numerical results. The underlying concept is to use randomness to solve problems that might be deterministic in principle. They are often used in physical and mathematical problems and are most useful when it is difficult or impossible to use other approaches. Monte Carlo methods are mainly used in three problem classes: optimization, numerical integration, and generating draws from a probability distribution. In physics-related problems, Monte Carlo methods are useful for simulating systems with many coupled degrees of freedom, such as fluids, disordered materials, strongly coupled solids, and cellular structures (see cellular Potts model, interacting particle systems, McKean–Vlasov processes, kinetic models of gases). Other examples include modeling phenomena with significant uncertainty in inputs such as the calculation of risk in b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, heating and cooling systems, transport systems, aircraft, watercraft, robotics, medical devices, weapons, and others. Mechanical engineering emerged as a field during the Industrial Revolution in Europe in the 18th century; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Tolerance

Engineering tolerance is the permissible limit or limits of variation in: # a physical dimension; # a measured value or physical property of a material, manufactured object, system, or service; # other measured values (such as temperature, humidity, etc.); # in engineering and safety, a physical distance or space (tolerance), as in a truck (lorry), train or boat under a bridge as well as a train in a tunnel (see structure gauge and loading gauge); # in mechanical engineering, the space between a bolt and a nut or a hole, etc. Dimensions, properties, or conditions may have some variation without significantly affecting functioning of systems, machines, structures, etc. A variation beyond the tolerance (for example, a temperature that is too hot or too cold) is said to be noncompliant, rejected, or exceeding the tolerance. Considerations when setting tolerances A primary concern is to determine how wide the tolerances may be without affecting other factors or the outcome of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Design

Product design as a verb is to create a new product to be sold by a business to its customers. A very broad coefficient and effective generation and development of ideas through a process that leads to new products. Thus, it is a major aspect of new product development. Product design process: the set of strategic and tactical activities, from idea generation to commercialization, used to create a product design. In a systematic approach, product designers conceptualize and evaluate ideas, turning them into tangible inventions and products. The product designer's role is to combine art, science, and technology to create new products that people can use. Their evolving role has been facilitated by digital tools that now allow designers to do things that include communicate, visualize, analyze, 3D modeling and actually produce tangible ideas in a way that would have taken greater human resources in the past. Product design is sometimes confused with (and certainly overlaps with) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Society Of Mechanical Engineers

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing education, training and professional development, codes and standards, research, conferences and publications, government relations, and other forms of outreach." ASME is thus an engineering society, a standards organization, a research and development organization, an advocacy organization, a provider of training and education, and a nonprofit organization. Founded as an engineering society focused on mechanical engineering in North America, ASME is today multidisciplinary and global. ASME has over 85,000 members in more than 135 countries worldwide. ASME was founded in 1880 by Alexander Lyman Holley, Henry Rossiter Worthington, John Edison Sweet and Matthias N. Forney in response to numerous steam boiler pressure vessel failures. Kno ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tolerance Coning

Tolerance coning is the engineering discipline of creating a budget of all tolerances that potentially add/subtract to affect adequacy of a particular parameter. This is particularly critical where stages of design/manufacture precede test/use. For example, when setting a test limit for a measurement on each manufactured item of some type, to assure that no bad items are shipped, the limit must be tighter than the requirement to allow for the worst case sum of measurement inaccuracies (e.g. equipment, test fixture etc.). The design of the item thus has to take into account not only the product requirement but also the test tolerances. The buildup of this budget is tolerance coning. Electronics engineers intuitively do tolerance coning and tend to formalise it for critical parameters. However it is also relevant to other engineering disciplines. See also * Test method * Engineering tolerance Engineering tolerance is the permissible limit or limits of variation in: # a phy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

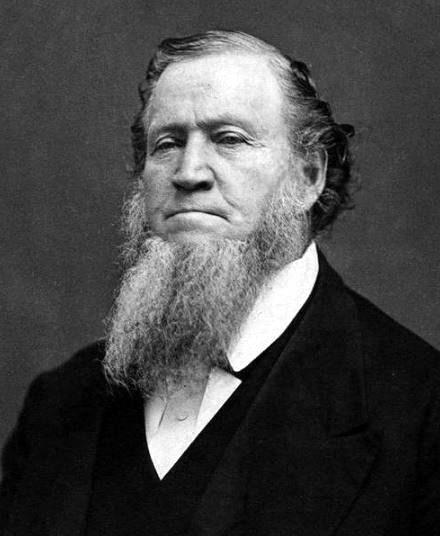

Brigham Young University

Brigham Young University (BYU, sometimes referred to colloquially as The Y) is a private research university in Provo, Utah. It was founded in 1875 by religious leader Brigham Young and is sponsored by the Church of Jesus Christ of Latter-day Saints (LDS Church). BYU offers a variety of academic programs including those in the liberal arts, engineering, agriculture, management, physical and mathematical sciences, nursing, and law. It has 186 undergraduate majors, 64 master's programs, and 26 doctoral programs. It is broadly organized into 11 colleges or schools at its main Provo campus, with some colleges and divisions defining their own admission standards. The university also administers two satellite campuses, one in Jerusalem and one in Salt Lake City, while its parent organization the Church Educational System (CES) sponsors sister schools in Hawaii and Idaho. The university is accredited by the Northwest Commission on Colleges and Universities. Almost all BYU students ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering branches. Mechanical engineering requires an understanding of core areas including mechanics, dynamics, thermodynamics, materials science, structural analysis, and electricity. In addition to these core principles, mechanical engineers use tools such as computer-aided design (CAD), computer-aided manufacturing (CAM), and product lifecycle management to design and analyze manufacturing plants, industrial equipment and machinery, heating and cooling systems, transport systems, aircraft, watercraft, robotics, medical devices, weapons, and others. Mechanical engineering emerged as a field during the Industrial Revolution in Europe in the 18th century; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_pg328_AMERICAN_SOCIETY_OF_MECHANICAL_ENGINEERS._12_WEST_31ST_STREET.jpg)