|

Tapered Roller Bearing

Tapered roller bearings are rolling element bearings that can support axial forces (i.e., they are good thrust bearings) as well as radial forces. Description The inner and outer ring raceways are segments of cones and the rollers are tapered so that the conical surfaces of the raceways, and the roller axes, if projected, would all meet at a common point on the main axis of the bearing. This geometry makes the motion of the cones remain coaxial, with no sliding motion between the raceways and the outside diameter of the rollers. This conical geometry creates a linear contact patch which permits greater loads to be carried than with spherical (ball) bearings, which have point contact. The geometry means that the tangential speeds of the surfaces of each of the rollers are the same as their raceways along the whole length of the contact patch and no differential scrubbing occurs. The rollers are stabilized and restrained by a flange on the inner ring, against which their la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry Timken

Henry Timken (August 16, 1831 in Bremen, Germany – March 16, 1909 in San Diego, California) was an inventor and businessman who founded the Timken Roller Bearing Company, later called the Timken Company. His family migrated to the United States when he was 7 years old. He began his business career in the St. Louis region. His inventions of an improved carriage spring and an improved roller bearing brought him the money needed to create a company dedicated to the latter. Biography Henry Timken was born in Bremen, now in Germany, and emigrated to the United States with his family when he was seven years old. The Timkens settled in Sedalia, Missouri; Henry left the family farm to apprentice under carriage-builder Caspar Schurmeier. Timken opened his own carriage-building company in St. Louis in 1855, and introduced several improvements to the carriages his firm produced, including his patented "Timken buggy spring", which made him a fortune. He patented an improved tapere ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Bearing

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements (such as balls or rollers) between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding. One of the earliest and best-known rolling-element bearings are sets of logs laid on the ground with a large stone block on top. As the stone is pulled, the logs roll along the ground with little sliding friction. As each log comes out the back, it is moved to the front where the block then rolls on to it. It is possible to imitate such a bearing by placing several pens or pencils on a table and placing an item on top of them. See " bearings" for more on the historical development of bearings. A rolling element rotary bearing uses a shaft in a much larger hole, and cylinders called "rollers" tightly fill the space between t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brinelling

Brinelling {{IPAc-en, ˈ, b, r, ɪ, n, ə, l, ɪ, ŋ is the permanent indentation of a hard surface. It is named after the Brinell scale of hardness, in which a small ball is pushed against a hard surface at a preset level of force, and the depth and diameter of the mark indicates the Brinell hardness of the surface. Brinelling is permanent plastic deformation of a surface, and usually occurs while two surfaces in contact are stationary (such as rolling elements and the raceway of a bearings) and the material yield strength has been exceeded. Brinelling is undesirable, as the parts often mate with other parts in very close proximity. The very small indentations can quickly lead to improper operation, such as chattering or excess vibration, which in turn can accelerate other forms of wear, such as spalling and ultimately, failure of the bearing. Introduction Brinelling is a material surface failure caused by Hertz contact stress that exceeds the material limit. It usually occurs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ball Bearing

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races. History Although bearings had been developed since ancient times, the first mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robot Combat

Robot combat is a mode of robot competition in which custom-built machines fight using various methods to incapacitate each other. The machines have generally been remote-controlled vehicles rather than autonomous robots. Robot combat competitions have been made into television series, including '' Robot Wars'' in the UK and ''Battlebots'' in the US. These shows were originally broadcast in the late 1990s to early 2000s and experienced revivals in the mid-2010s. As well as televised competitions, smaller robot combat events are staged for live audiences such as those organized by the Robot Fighting League. Robot builders are generally hobbyists and the complexity and cost of their machines can vary substantially. Robot combat uses weight classes, with the heaviest robots able to exert more power and destructive capabilities. The rules of competitions are designed for the safety of the builders, operators, and spectators while also providing for an entertaining spectacle. Robo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Bearing

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings. Thus, it is possible for some fluid bearings to have near-zero wear if operated correctly. They can be broadly classified into two types: fluid dynamic bearings (also known as hydrodynamic bearings) and hydrostatic bearings. Hydrostatic bearings are externally pressurized fluid bearings, where the fluid is usually oil, water or air, and is pressurized by a pump. Hydrodynamic bearings rely on the high speed of the journal (the part of the shaft resting on the fluid) to pressurize the fluid in a wedge between the faces. Fluid bearings are frequently used in high load, high speed or high precision applications where ordinary ball bearings would have shor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Journal Bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Patch

Contact patch is the portion of a vehicle's tire that is in actual contact with the road surface. It is commonly used in the discussion of pneumatic (i.e. pressurized) tires, where the term is used strictly to describe the portion of the tire’s tread that touches the road surface. The term “footprint” is used almost synonymously. Solid wheels also exhibit a contact patch which is generally smaller than the pneumatic “footprint”. Contact patch size The contact patch is the only connection between the road and the vehicle. Pneumatic rubber tires The size and shape of the contact patch, as well as the pressure distribution within the contact patch, are important to the ride qualities and handling characteristics of a vehicle. Since the wear characteristics of tires is a highly competitive area between tire manufacturers, a lot of the research done concerning the contact patch is considered highly proprietary and, therefore, very little is published on the subject. Becaus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling Cone Motion

Rolling cone motion is the rolling motion generated by a cone rolling over another cone. In rolling cone motion, at least one of the cones is convex, while the other cone may be either convex, or concave, or a flat surface (a flat surface can be regarded as a special case of a cone whose apex angle equals \pi). The distinguishing characteristic of a rolling cone, in relation to other axially symmetrical rollers (cylinder, sphere, round disk), is that while rolling on a flat surface, the cone's center of gravity performs a circular motion rather than a linear one. Another unique characteristic is that one of its points (its apex) is at rest throughout the entire motion. Kinematics The motion of a rolling cone can be described as a superposition of a rotational motion of the cone around its axis of symmetry, and a rotary motion of its axis around the axis of symmetry of the stationary cone. The ratio between the angular velocities of these two motions is given by: :\frac = wher ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

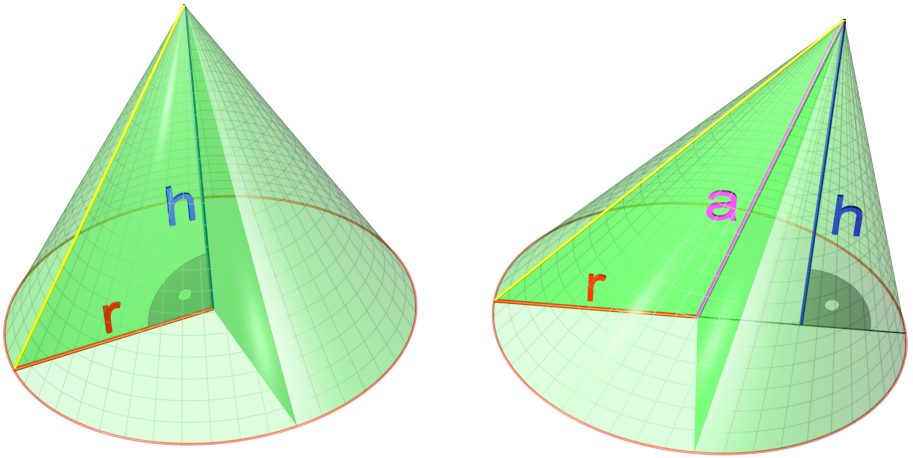

Cone (geometry)

A cone is a three-dimensional geometric shape that tapers smoothly from a flat base (frequently, though not necessarily, circular) to a point called the apex or vertex. A cone is formed by a set of line segments, half-lines, or lines connecting a common point, the apex, to all of the points on a base that is in a plane that does not contain the apex. Depending on the author, the base may be restricted to be a circle, any one-dimensional quadratic form in the plane, any closed one-dimensional figure, or any of the above plus all the enclosed points. If the enclosed points are included in the base, the cone is a solid object; otherwise it is a two-dimensional object in three-dimensional space. In the case of a solid object, the boundary formed by these lines or partial lines is called the ''lateral surface''; if the lateral surface is unbounded, it is a conical surface. In the case of line segments, the cone does not extend beyond the base, while in the case of half-lin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |