|

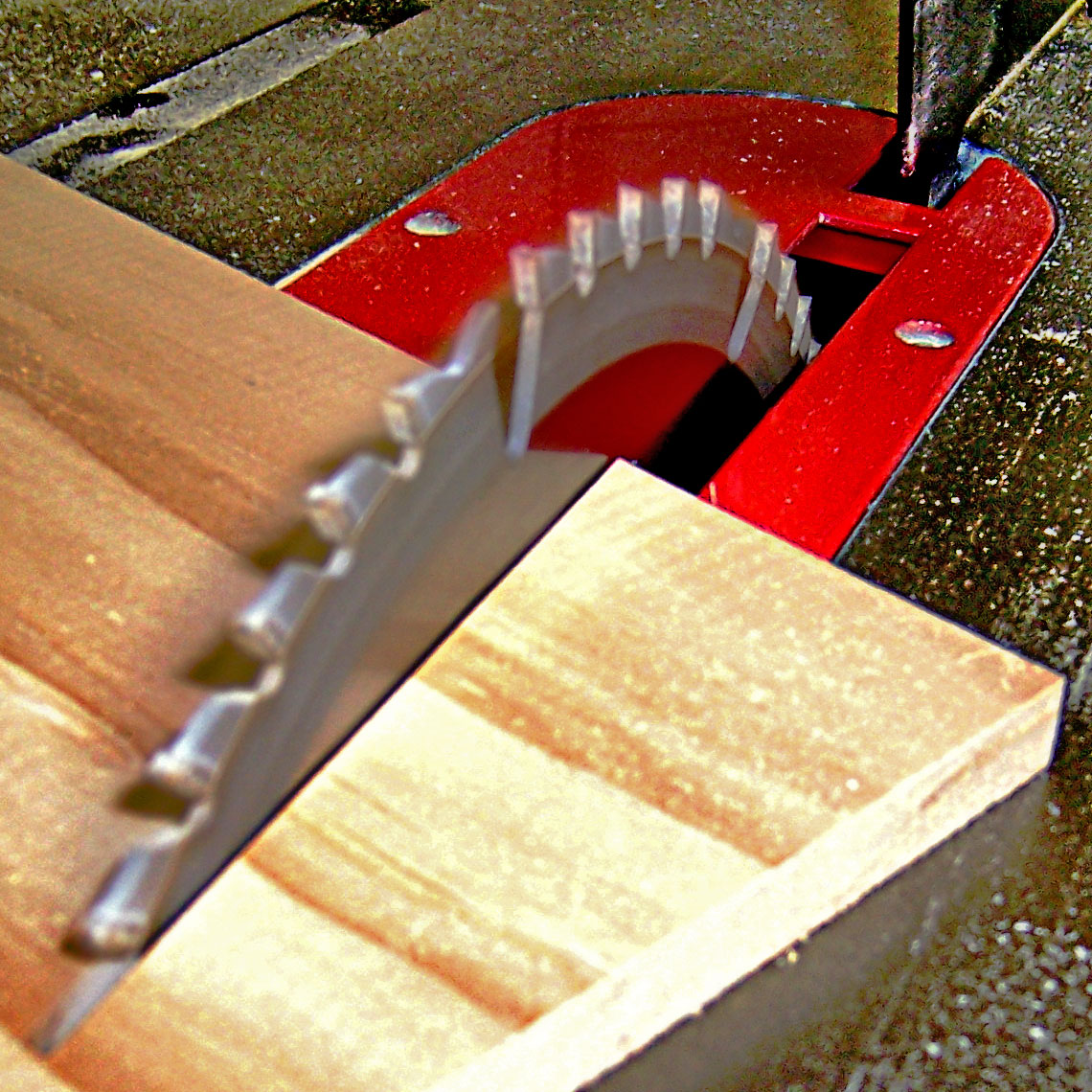

Tongue And Groove

Tongue and groove is a method of fitting similar objects together, edge to edge, used mainly with wood, in flooring, parquetry, panelling, and similar constructions. Tongue and groove joints allow two flat pieces to be joined strongly together to make a single flat surface. Before plywood became common, tongue and groove boards were also used for sheathing buildings and to construct concrete formwork. A strong joint, the tongue and groove joint is widely used for re-entrant angles. The effect of wood shrinkage is concealed when the joint is beaded or otherwise moulded.Tongue and GrooveWoodworkDetails.com/ref> In expensive cabinet work, glued dovetail and multiple tongue and groove are used. Each piece has a slot (the '' groove'' or '' dado'') cut all along one edge, and a thin, deep ridge (the ''tongue'') on the opposite edge. The tongue projects a little less than the depth of the groove. Two or more pieces thus fit together closely. The joint is not normally glued, as shri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Wood

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibres, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material. The panels vary in size but can range upwards of and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance. Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulley

A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt. In the case of a pulley supported by a frame or shell that does not transfer power to a shaft, but is used to guide the cable or exert a force, the supporting shell is called a block, and the pulley may be called a sheave. A pulley may have a groove or grooves between flanges around its circumference to locate the cable or belt. The drive element of a pulley system can be a rope, cable, belt, or chain. The earliest evidence of pulleys dates back to Ancient Egypt in the Twelfth Dynasty (1991-1802 BCE) and Mesopotamia in the early 2nd millennium BCE. In Roman Egypt, Hero of Alexandria (c. 10-70 CE) identified the pulley as one of six simple machines used to lift weights. Pulleys are assembled to form a block and tackle in order to provide mechanical advantage to apply large forces. Pulle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Larssen Sheet Piling

Larssen sheet piling is a kind of sheet piling retaining wall. Segments with indented profiles (troughs) interlock to form a wall with alternating indents and outdents. The troughs increase resistance to bending. The segments are typically made of steel or another metal. Larssen sheet piling was developed in 1906 by Tryggve Larssen. Its applications include piers, oil terminal An oil terminal (also called a tank farm, tankfarm, oil installation or oil depot) is an industrial facility for the storage of oil, petroleum and petrochemical Petrochemicals (sometimes abbreviated as petchems) are the chemical products obt ...s, waste storage facilities, shoreline protection, bridges, houses, buildings, dry docks other construction sites and for the strengthening of pond banks, preventing slumping into a pit and flooding. Construction Lengths can reach 36 meters. Each segment is flipped 180° versus the preceding segment. The segments lock together using a variety of interconn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Groove (engineering)

In manufacturing or mechanical engineering a groove is a long and narrow indentation built into a material, generally for the purpose of allowing another material or part to move within the groove and be guided by it. Examples include: # A canal cut in a hard material, usually metal. This canal can be round, oval or an arc in order to receive another component such as a boss, a tongue or a gasket. It can also be on the circumference of a dowel, a bolt, an axle or on the outside or inside of a tube or pipe etc. This canal may receive a circlip, an o-ring, or a gasket. # A depression on the entire circumference of a cast or machined wheel, a pulley or sheave. This depression may receive a cable, a rope or a belt. # A longitudinal channel formed in a hot rolled rail profile such as a grooved rail. This groove is for the flange on a train wheel. Grooves were used by ancient Roman engineers to survey land. See also * Fluting (architecture) * Gland (engineering) * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gland (engineering)

A stuffing box or gland package is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements. Components A stuffing box of a sailing boat will have a stern tube that is slightly bigger than the prop shaft. It will also have packing nut threads or a gland nut. The packing is inside the gland nut and creates the seal. The shaft is wrapped by the packing and put in the gland nut. Through tightening it onto the stern tube, the packing is compressed, creating a seal against the shaft. , WindCheck Magazine, Retrieved April 27, 2016. Creating a proper plunger alignment is critical for correct flow and a long wear life. Stuffing box components are of stainless steel, brass or other application-specific m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluting (architecture)

Fluting in architecture consists of shallow grooves running along a surface. The term typically refers to the grooves (flutes) running vertically on a column shaft or a pilaster, but need not necessarily be restricted to those two applications. If the hollowing out of material meets in a point, the point (sharp ridge) is called an arris. If the raised ridge between two flutes is blunt, the ridge is a . Purpose Fluting promotes a play of light on a column which helps the column appear more perfectly round than a smooth column. As a strong vertical element it also has the visual effect of minimizing any horizontal joints. Greek architects viewed rhythm as an important design element. As such, fluting was often used on buildings and temples to increase the sense of rhythm. It may also be incorporated in columns to make them look thinner, lighter, and more elegant. There is debate as to whether fluting was originally used in imitation of ancient woodworking practices, mimicking ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carpentry

Carpentry is a skilled trade and a craft in which the primary work performed is the cutting, shaping and installation of building materials during the construction of buildings, ships, timber bridges, concrete formwork, etc. Carpenters traditionally worked with natural wood and did rougher work such as framing, but today many other materials are also used and sometimes the finer trades of cabinetmaking and furniture building are considered carpentry. In the United States, 98.5% of carpenters are male, and it was the fourth most male-dominated occupation in the country in 1999. In 2006 in the United States, there were about 1.5 million carpentry positions. Carpenters are usually the first tradesmen on a job and the last to leave. Carpenters normally framed post-and-beam buildings until the end of the 19th century; now this old-fashioned carpentry is called timber framing. Carpenters learn this trade by being employed through an apprenticeship training—normally 4 years ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cabinet Making

A cabinet is a case or cupboard with shelves and/or drawers for storing or displaying items. Some cabinets are stand alone while others are built in to a wall or are attached to it like a medicine cabinet. Cabinets are typically made of wood (solid or with veneers or artificial surfaces), coated steel (common for medicine cabinets), or synthetic materials. Commercial grade cabinets usually have a melamine-particleboard substrate and are covered in a high pressure decorative laminate, commonly referred to as Wilsonart or Formica. Cabinets sometimes have one or more doors on the front, which are mounted with door hardware, and occasionally a lock. Cabinets may have one or more doors, drawers, and/or shelves. Short cabinets often have a finished surface on top that can be used for display, or as a working surface, such as the countertops found in kitchens. A cabinet intended to be used in a bedroom and with several drawers typically placed one above another in one or more co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Router (woodworking)

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs (hollows out) an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools. There is also a traditional hand tool known as a router plane, a form of hand plane with a broad base and a narrow blade projecting well beyond the base plate. CNC wood routers add the advantages of computer numerical control (CNC). The laminate trimmer is a smaller, lighter version of the router. Although it is designed for trimming laminates, it can also be used for smaller general routing work. Rotary tools can also be used similarly to routers with the right bits and accessories (such as plastic router bases). History Before power routers exist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Plane

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used. Generally, all planes are used to flatten, reduce the thickness of, and impart a smooth surface to a rough piece of lumber or timber. Planing is also used to produce horizontal, vertical, or inclined flat surfaces on workpieces usually too large for shaping, where the integrity of the whole requires the same smooth surface. Special types of planes are designed to cut joints or decorative mouldings. Hand planes are generally the combination of a cutting edge, such as a sharpened metal plate, attached to a firm body, that when moved over a wood surface, take up relatively uniform shavings, by nature of the body riding on the 'high spots' in the wood, and also by providing a relatively constant angle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Circular Saw Bench

A table saw (also known as a sawbench or bench saw in England) is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor (either directly, by belt, or by gears). The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut. In most modern table saws, the depth of the cut is varied by moving the blade up and down: the higher the blade protrudes above the table, the deeper the cut that is made in the material. In some early table saws, the blade and arbor were fixed, and the table was moved up and down to expose more or less of the blade. The angle of cut is controlled by adjusting the angle of blade. Some earlier saws angled the table to control the cut angle. Types The general types of table saws are compact, benchtop, jobsite, contractor, hybrid, cabinet, and sliding table saws. Benchtop Benchtop table saws are lightweight and are designed to be placed on a table ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |