|

Stress Risers

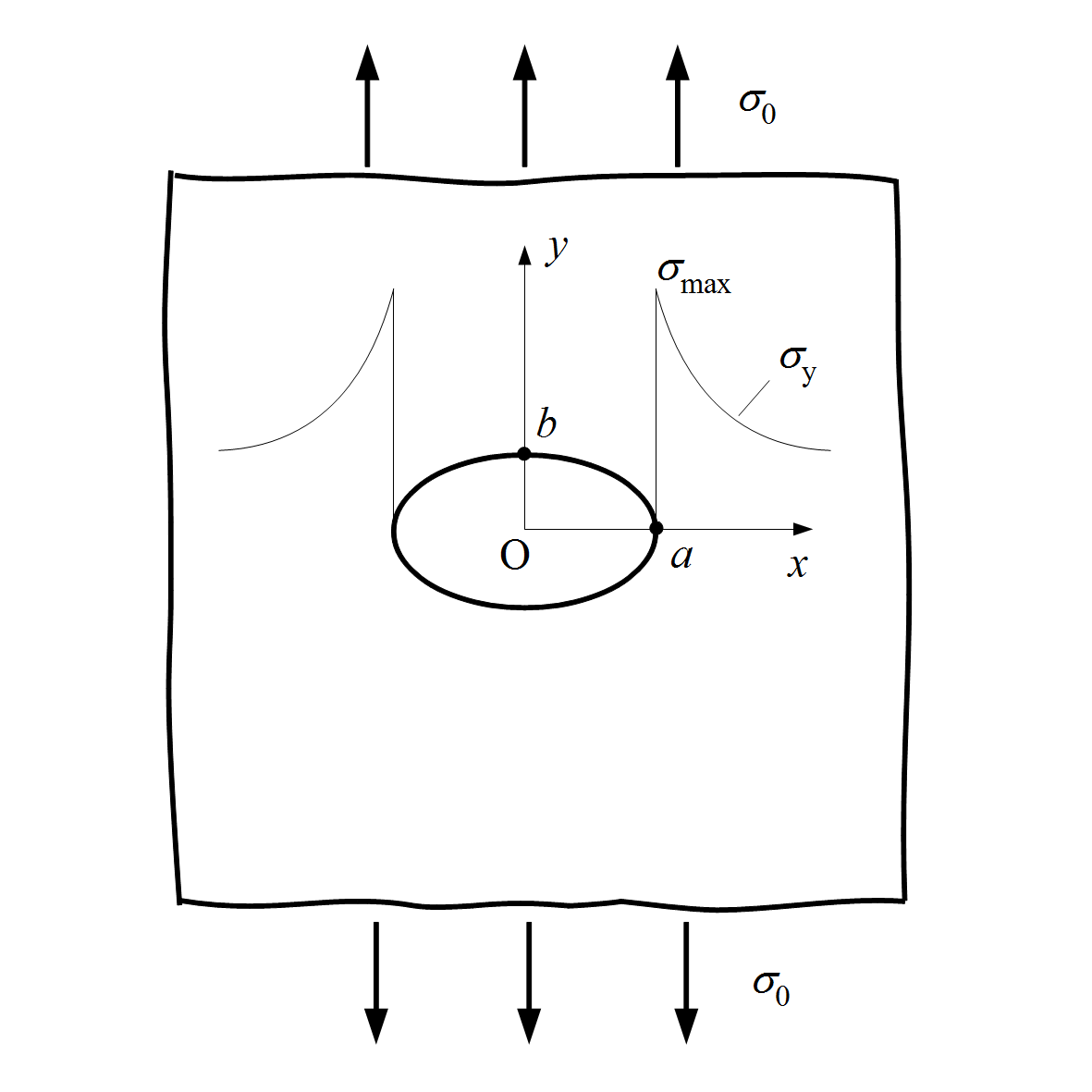

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip. For ductile mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microvoid Coalescence

Microvoid coalescence (MVC) is a high energy microscopic fracture mechanism observed in the majority of metallic alloys and in some engineering plastics. Fracture process MVC proceeds in three stages: nucleation, growth, and coalescence of microvoids. The nucleation of microvoids can be caused by particle cracking or interfacial failure between precipitate particles and the matrix. Additionally, microvoids often form at grain boundaries or inclusions within the material. Microvoids grow during plastic flow of the matrix, and microvoids coalesce when adjacent microvoids link together or the material between microvoids experiences necking. Microvoid coalescence leads to fracture. Void growth rates can be predicted assuming continuum plasticity using the Rice-Tracey model: \ln\left(\frac\right) = \int\limits_^ A\left(\frac\right)d\epsilon_v^p where A is a constant typically equal to 0.283 (but dependent upon the stress triaxiality), \sigma_ is the yield stress, \sigma_m is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal ''crystallising'' because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air. It counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engines. Common examples of aircraft include airplanes, helicopters, airships (including blimps), gliders, paramotors, and hot air balloons. The human activity that surrounds aircraft is called ''aviation''. The science of aviation, including designing and building aircraft, is called '' aeronautics.'' Crewed aircraft are flown by an onboard pilot, but unmanned aerial vehicles may be remotely controlled or self-controlled by onboard computers. Aircraft may be classified by different criteria, such as lift type, aircraft propulsion, usage and others. History Flying model craft and stories of manned flight go back many centuries; however, the first manned ascent — and safe descent — in modern times took place by larger hot-air ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

De Havilland Comet

The de Havilland DH.106 Comet was the world's first commercial jet airliner. Developed and manufactured by de Havilland in the United Kingdom, the Comet 1 prototype first flew in 1949. It featured an aerodynamically clean design with four de Havilland Ghost turbojet engines buried in the wing roots, a pressurised cabin, and large square windows. For the era, it offered a relatively quiet, comfortable passenger cabin and was commercially promising at its debut in 1952. Within a year of entering airline service, problems started to emerge, three Comets being lost within twelve months in highly publicised accidents, after suffering catastrophic in-flight break-ups. Two of these were found to be caused by structural failure resulting from metal fatigue in the airframe, a phenomenon not fully understood at the time; the other was due to overstressing of the airframe during flight through severe weather. The Comet was withdrawn from service and extensively tested. Design and cons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cracking In Concrete Due To Stress Concentration

Cracking may refer to: * Cracking, the formation of a fracture or partial fracture in a solid material studied as fracture mechanics ** Performing a sternotomy * Fluid catalytic cracking, a catalytic process widely used in oil refineries for cracking large hydrocarbon molecules into smaller molecules * Cracking (chemistry), the decomposition of complex organic molecules into smaller ones * Cracking joints, the practice of manipulating one's bone joints to make a sharp sound * Cracking codes, see cryptanalysis * Whip cracking * Safe cracking * ''Crackin, band featuring Lester Abrams * Packing and cracking, a method of creating voting districts to give a political party an advantage In computing: * Another name for security hacking; the practice of defeating computer security. * Password cracking, the process of discovering the plaintext of an encrypted computer password. * Software cracking, the defeating of software copy protection. See also * Crack (other) *Crack ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antler ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite Element Method

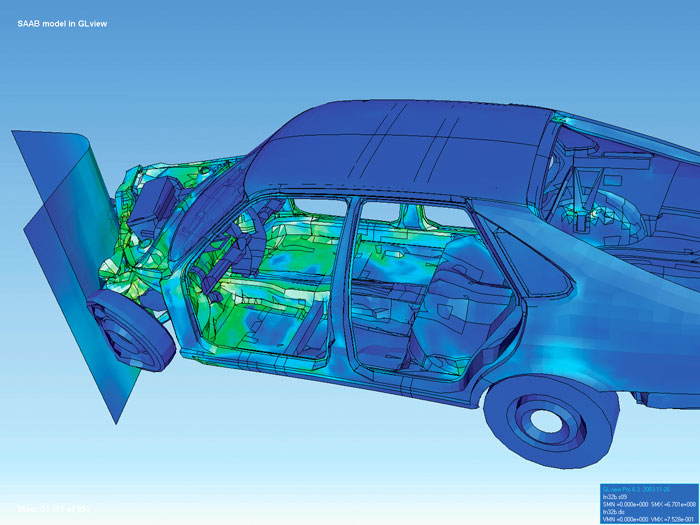

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strain Gauge

A strain gauge (also spelled strain gage) is a device used to measure strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an insulating flexible backing which supports a metallic foil pattern. The gauge is attached to the object by a suitable adhesive, such as cyanoacrylate. As the object is deformed, the foil is deformed, causing its electrical resistance to change. This resistance change, usually measured using a Wheatstone bridge, is related to the strain by the quantity known as the gauge factor. History Edward E. Simmons and Professor Arthur C. Ruge independently invented the strain gauge. Simmons was involved in a research project by Dätwyler and Clark at Caltech between 1936 and 1938. They researched the stress-strain behavior of metals under shock loads. Simmon came up with an original way to measure the force introduced into the sample by equipping a dynamometer with fine resistance wires ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photoelasticity

Photoelasticity describes changes in the optical properties of a material under mechanical deformation. It is a property of all dielectric media and is often used to experimentally determine the stress distribution in a material, where it gives a picture of stress distributions around discontinuities in materials. Photoelastic experiments (also informally referred to as ''photoelasticity'') are an important tool for determining critical stress points in a material, and are used for determining stress concentration in irregular geometries. History The photoelastic phenomenon was first discovered by the Scottish physicist David Brewster, who immediately recognized it as stress-induced birefringence. That diagnosis was confirmed in a direct refraction experiment by Augustin-Jean Fresnel.A. Fresnel, "Note sur la double réfraction du verre comprimé" (read 16 September 1822), ''Annales de Chimie et de Physique'', Ser. 2, vol. 20, pp. 376–83 (nominally f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radius Of Curvature (applications)

In differential geometry, the radius of curvature, , is the reciprocal of the curvature. For a curve, it equals the radius of the circular arc which best approximates the curve at that point. For surfaces, the radius of curvature is the radius of a circle that best fits a normal section or combinations thereof. Definition In the case of a space curve, the radius of curvature is the length of the curvature vector. In the case of a plane curve, then is the absolute value of : R \equiv \left, \frac \ = \frac, where is the arc length from a fixed point on the curve, is the tangential angle and is the curvature. Formula In 2D If the curve is given in Cartesian coordinates as , i.e., as the graph of a function, then the radius of curvature is (assuming the curve is differentiable up to order 2): : R =\left, \frac \, \qquad\mbox\quad y' = \frac,\quad y'' = \frac, and denotes the absolute value of . If the curve is given parametrically by functions and , then the radius ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Notch (engineering)

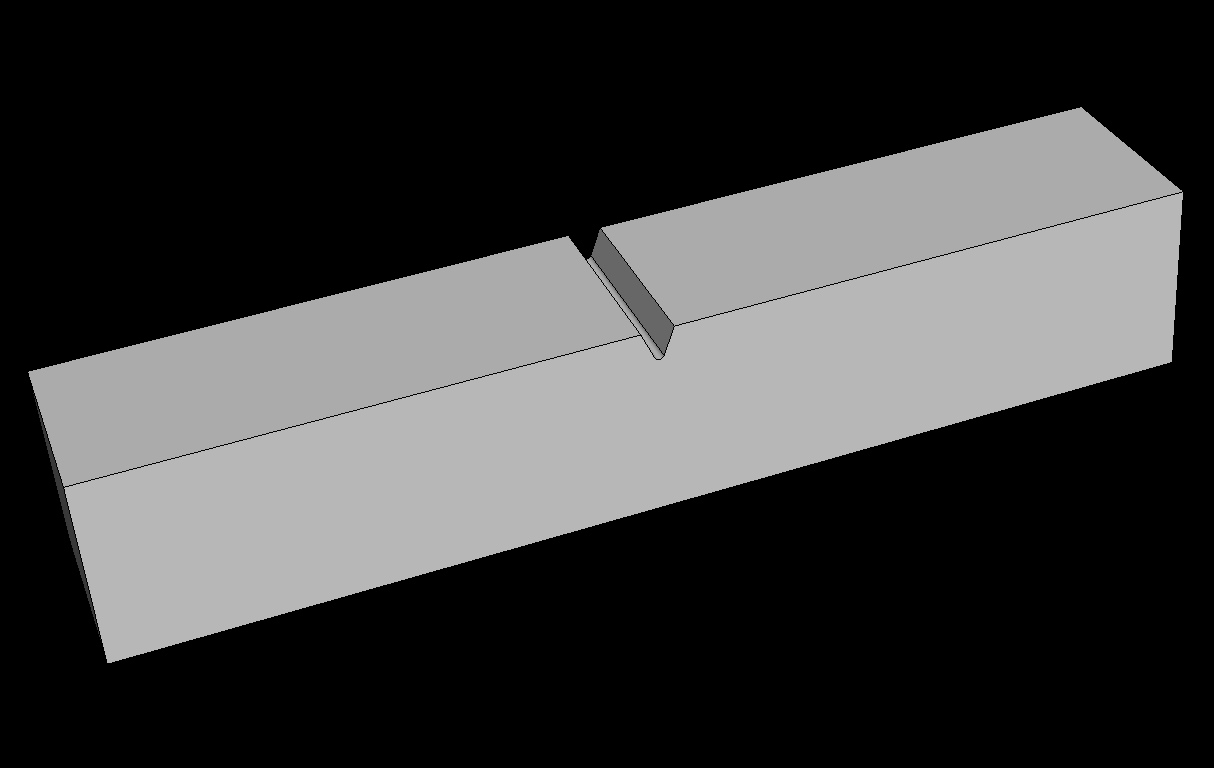

In mechanical engineering and materials science, a notch refers to a V-shaped, U-shaped, or semi-circular defect deliberately introduced into a planar material. In structural components, a notch causes a stress concentration which can result in the initiation and growth of fatigue cracks. Notches are used in materials characterization to determine fracture mechanics related properties such as fracture toughness and rates of fatigue crack growth. Notches are commonly used in material impact tests where a morphological crack of a controlled origin is necessary to achieve standardized characterization of fracture resistance of the material. The most common is the Charpy impact test, which uses a pendulum hammer (striker) to strike a horizontal notched specimen. The height of its subsequent swing-through is used to determine the energy absorbed during fracture. The Izod impact strength test uses a circular notched vertical specimen in a cantilever configuration. Charpy testing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |