|

STACKER

A stacker is a large machine used in bulk material handling. Its function is to pile bulk material such as limestone, ores and cereals on to a stockpile. A reclaimer can be used to recover the material. Gold dredges in Alaska had a stacker that was a fixed part of the dredge. It carried over-size material to the tailings pile. Stackers are nominally rated for capacity in tonnes per hour (tph). They normally travel on a rail between stockpiles in the stockyard. A stacker can usually move in at least two directions: horizontally along the rail and vertically by luffing (raising and lowering) its boom. Luffing of the boom minimises dust by reducing the distance that material such as coal needs to fall to the top of the stockpile. The boom is luffed upwards as the height of the stockpile increases. Some stackers can rotate the boom. This allows a single stacker to form two stockpiles, one on either side of the conveyor. Stackers are used to stack in different patterns, su ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reclaimer

A reclaimer is a large machine used in bulk material handling applications. A reclaimer's function is to recover bulk material such as ores and cereals from a stockpile. A stacker is used to stack the material. Reclaimers are volumetric machines and are rated in m3/h (cubic meters per hour) for capacity, which is often converted to t/h (tonnes per hour) based on the average bulk density of the material being reclaimed. Reclaimers normally travel on a rail between stockpiles in the stockyard. A bucket wheel reclaimer can typically move in three directions: horizontally along the rail; vertically by "luffing" its boom and rotationally by slewing its boom. Reclaimers are generally electrically powered by means of a trailing cable. Reclaimer types Bucket wheel reclaimers use "bucket wheels" to remove material from the pile they are reclaiming. Scraper reclaimers use a series of scrapers on a chain to reclaim the material. The reclaimer structure can be of a number of types, i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reclaimer

A reclaimer is a large machine used in bulk material handling applications. A reclaimer's function is to recover bulk material such as ores and cereals from a stockpile. A stacker is used to stack the material. Reclaimers are volumetric machines and are rated in m3/h (cubic meters per hour) for capacity, which is often converted to t/h (tonnes per hour) based on the average bulk density of the material being reclaimed. Reclaimers normally travel on a rail between stockpiles in the stockyard. A bucket wheel reclaimer can typically move in three directions: horizontally along the rail; vertically by "luffing" its boom and rotationally by slewing its boom. Reclaimers are generally electrically powered by means of a trailing cable. Reclaimer types Bucket wheel reclaimers use "bucket wheels" to remove material from the pile they are reclaiming. Scraper reclaimers use a series of scrapers on a chain to reclaim the material. The reclaimer structure can be of a number of types, i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Homogenization

Coal homogenization refers to the process of mixing coal to reduce the variance of the product supplied. This homogenization process is performed during the coal stockpiling operation. Although the terms blending and homogenization are often used interchangeably, there are differences as the definitions show. The most notable difference is that blending refers to stacking coal from different sources together on one stockpile. The reclaimed heap would then typically have a weighted average output quality of the input sources. In contrast, homogenization focuses on reducing the variance of only one source. A blending operation will cause some homogenization. Definitions Mixing Mixing is defined as a random rearrangement of particles by means of mechanical energy, e.g. rotary devices in a fixed volume. Traces of individual components can still be located within a small quantity of the mixed material of two or more material types. Application: small-scale storage. Blending ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gold Dredge

A gold dredge is a placer mining machine that extracts gold from sand, gravel, and dirt using water and mechanical methods. The original gold dredges were large, multi-story machines built in the first half of the 1900s. Small suction machines are currently marketed as "gold dredges" to individuals seeking gold: just offshore from the beach of Nome, Alaska, for instance. A large gold dredge uses a mechanical method to excavate material (sand, gravel, dirt, etc.) using steel "buckets" on a circular, continuous "bucketline" at the front end of the dredge. The material is then sorted/sifted using water. On large gold dredges, the buckets dump the material into a steel rotating cylinder (a specific type of trommel called "the screen") that is sloped downward toward a rubber belt (the stacker) that carries away oversize material (rocks) and dumps the rocks behind the dredge. The cylinder has many holes in it to allow undersized material (including gold) to fall into a sluice ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stockpile

A stockpile is a pile or storage location for bulk materials, forming part of the bulk material handling process. Stockpiles are used in many different areas, such as in a port, refinery or manufacturing facility. The stockpile is normally created by a stacker. A reclaimer is used to recover the material. Stockpiles are normally stacked in stockyards in refineries, ports and mine sites. A simple stockpile is formed by machinery dumping coal into a pile, either from dump trucks, pushed into heaps with bulldozers or from conveyor booms. More controlled stockpiles are formed using stackers to form piles along the length of a conveyor, and reclaimers to retrieve the coal when required for product loading, etc. Individuals may also choose to stockpile certain commodities (e.g. food, medical supplies), that they fear may not be available to purchase in the future. For example, in March 2019, one in ten British shoppers were reported to be stockpiling food prior to Brexit. In the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering Vehicles

Heavy equipment or heavy machinery refers to heavy-duty vehicles specially designed to execute construction tasks, most frequently involving earthwork operations or other large construction tasks. ''Heavy equipment'' usually comprises five equipment systems: the implement, traction, structure, power train, and control/information. Heavy equipment has been used since at least the 1st century BC when the ancient Roman engineer Vitruvius described a crane in '' De architectura'' when it was powered via human or animal labor. Heavy equipment functions through the mechanical advantage of a simple machine, the ratio between input force applied and force exerted is multiplied, making tasks which could take hundreds of people and weeks of labor without heavy equipment far less intensive in nature. Some equipment uses hydraulic drives as a primary source of motion. The term "plant" is used to refer to any mobile type of heavy machinery. History The use of heavy equipment ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulk Material Handling

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps.http://practicalmaintenance.net/wp-content/uploads/Maintenance-of-Ash-Handling-Plants-and-Pneumatic-Conveying-Systems.pdf Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more. Major characteristics of bulk materials, so far as their handling is concerned, are: lump size, bulk weight (densit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bulk Material Handling

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps.http://practicalmaintenance.net/wp-content/uploads/Maintenance-of-Ash-Handling-Plants-and-Pneumatic-Conveying-Systems.pdf Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more. Major characteristics of bulk materials, so far as their handling is concerned, are: lump size, bulk weight (densit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Krupp Stacker Rtca Kestrel Mine

The Krupp family (see pronunciation), a prominent 400-year-old German dynasty from Essen, is notable for its production of steel, artillery, ammunition and other armaments. The family business, known as Friedrich Krupp AG (Friedrich Krupp AG Hoesch-Krupp after acquiring Hoesch AG in 1991 and lasting until 1999), was the largest company in Europe at the beginning of the 20th century, and was the premier weapons manufacturer for Germany in both world wars. Starting from the Thirty Years' War until the end of the Second World War, it produced battleships, U-boats, tanks, howitzers, guns, utilities, and hundreds of other commodities. The dynasty began in 1587 when trader Arndt Krupp moved to Essen and joined the merchants' guild. He bought and sold real estate, and became one of the city's richest men. His descendants produced small guns during the Thirty Years' War and eventually acquired fulling mills, coal mines and an iron forge. During the Napoleonic Wars, Friedrich Krupp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bevel Gear

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone, known as a pitch cone. Bevel gears transfer the energy from linear to vertical power, making it very useful in machines widely used in mechanical settings. Introduction Two important concepts in gearing are pitch surface and pitch angle. The pitch surface of a gear is the imaginary toothless surface that you would have by averaging out the peaks and valleys of the individual teeth. The pitch surface of an ordinary gear is the shape of a cylinder. The pitch angle of a gear is the angle between the face of the pitch surface and the axis. The most familiar kinds of bevel gears have pitch angles of less than 90 degrees and therefore are cone-shaped. This type of bevel gear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Coupling

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power.Fluid coupling ''encyclopedia2.thefreedictionary.com'' It has been used in s as an alternative to a mechanical . It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

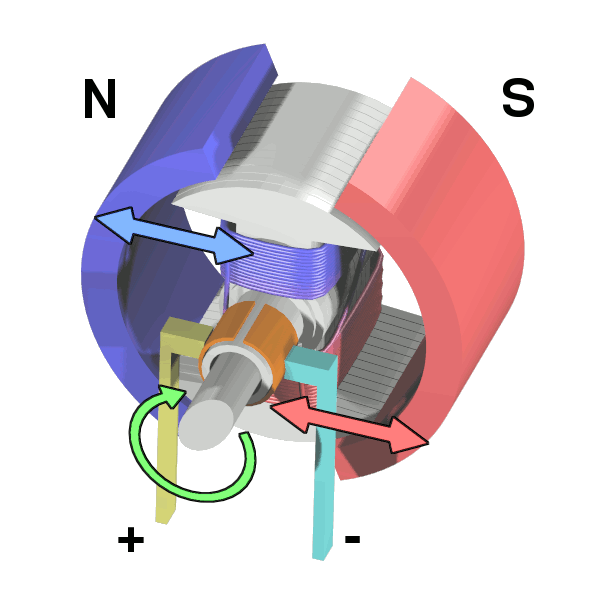

DC Motor

A DC motor is any of a class of rotary electrical motors that converts direct current (DC) electrical energy into mechanical energy. The most common types rely on the forces produced by induced magnetic fields due to flowing current in the coil. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor. DC motors were the first form of motors widely used, as they could be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field windings. Small DC motors are used in tools, toys, and appliances. The universal motor, a lightweight brushed motor used for portable power tools and appliances can operate on direct current and alternating current. Larger DC motors are currently used in propulsion of electric vehicle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)