|

Skelp

Skelp (sometimes spelled scelp) is wrought iron or steel that is rolled or forged into narrow strips and ready to be made into pipe or tubing by being bent (into a cylindrical shape) and welded. The word is most commonly used in the traditional terminology of smithing and in the iron and steel industries. Before the 20th century, the welding was likely to be forge welding. In the 20th and 21st centuries, it has been likelier to be arc welding or gas welding. In the context of traditional gunsmithing, one way to make gun barrels has been to make them from skelp, like one would make other pipe or tubing. Barrels made from skelp have typically been thought of as having inferior quality. (Pipe made from skelp can be perfectly acceptable in quality, but a gun barrel must withstand much higher pressures than most pipes.) Cheap gun barrels could be made this way in the Damascus method—wrapping the skelp around a mandrel to make spirals which were then hammered and forged into a tube. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to structural failure, failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welding, forge welded, but is more difficult to welding, weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is Carbon steel#Mild or low-carbon steel, mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

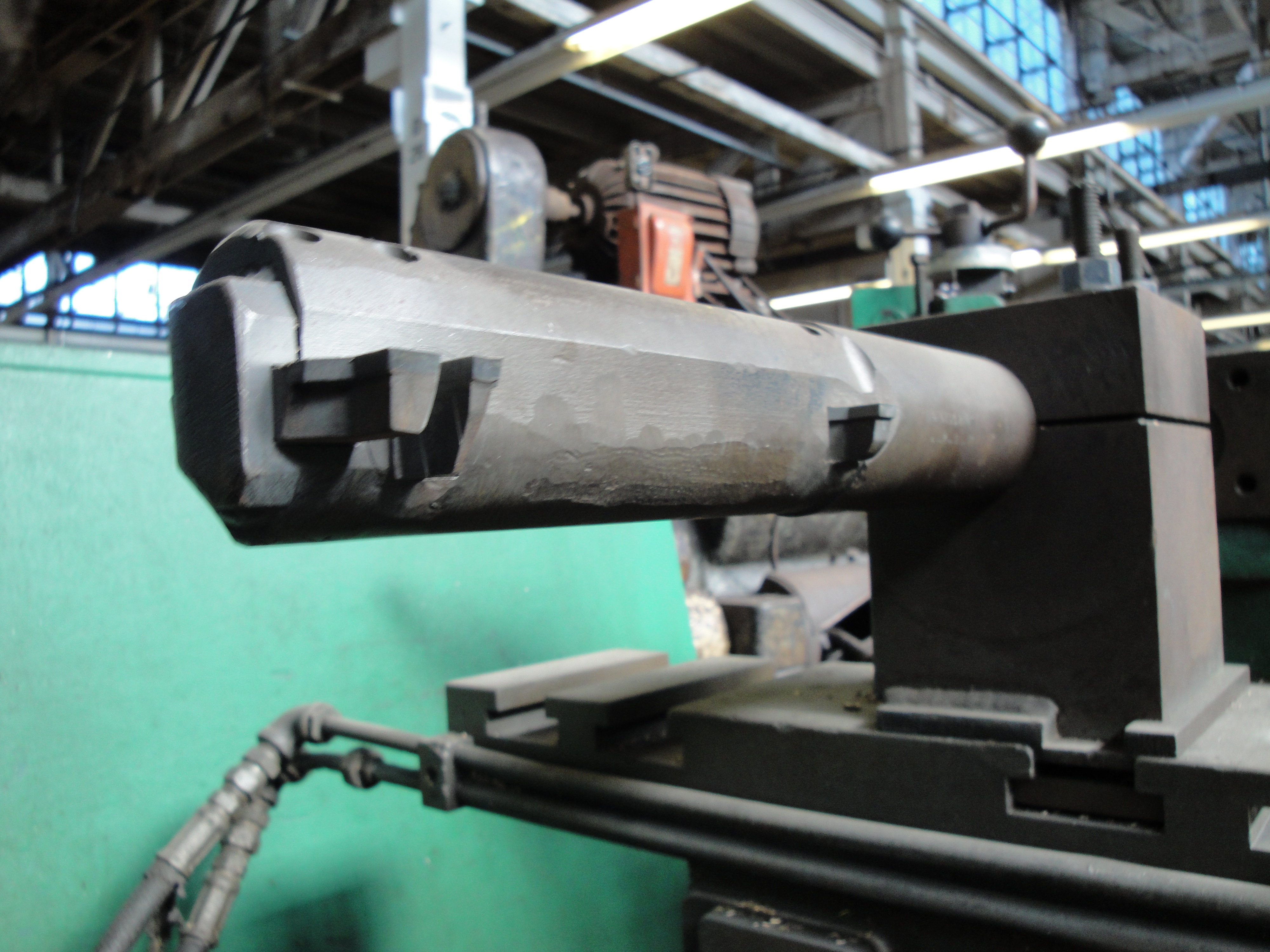

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boring (manufacturing)

In machining, boring is the process of enlarging a hole that has already been drilled (or cast) by means of a single-point cutting tool (or of a boring head containing several such tools), such as in boring a gun barrel or an engine cylinder. Boring is used to achieve greater accuracy of the diameter of a hole, and can be used to cut a tapered hole. Boring can be viewed as the internal-diameter counterpart to turning, which cuts external diameters. There are various types of boring. The boring bar may be supported on both ends (which only works if the existing hole is a through hole), or it may be supported at one end (which works for both, through holes and blind holes). Lineboring (line boring, line-boring) implies the former. Backboring (back boring, back-boring) is the process of reaching through an existing hole and then boring on the "back" side of the workpiece (relative to the machine headstock). Because of the limitations on tooling design imposed by the fac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gun Drill

Gun drills (through coolant drill) are straight fluted drills which allow cutting fluid (either compressed air or a suitable liquid) to be injected through the drill's hollow body to the cutting face. They are used for deep hole drilling—a depth-to-diameter ratio of 300:1 or more is possible. Gun barrels are the obvious example; hence the name. Other uses include moldmaking, diemaking, and the manufacture of combustion engine parts such as crankcase, cylinder head, and woodwind musical instruments, such as uilleann pipes, as gun drills can drill long straight holes in metal, wood, and some plastics. The coolant provides lubrication and cooling to the cutting edges and removes the swarf or chips from the hole. Modern gun drills use carbide tips to prolong life and reduce total cost when compared with steel tips. Speed of drilling depends on the material being drilled, rotational speed, and the drill diameter; a high speed drill can cut a hole in P20 steel at 30 inch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spindle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to increased efficiency and ease of use. Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for miniature applications. History Around 35,000 BC, ''Homo sapiens'' discovered the benefits of the application of rotary tools. This would have rudimentarily consisted of a pointed rock being spun between the hands to bore a hole through another material. This led to the hand drill, a smooth stick, that was sometimes attached to flint point, and was rubbed between the palms. This was used by many ancient civilizations around the world including the Mayans. The earliest perforated artifacts, such as bone, ivory, shells, and antler ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabrication (metal)

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product. Large fab shops employ a multitude of value-added processes, including welding, cutting, forming and machining. As with other manufacturing processes, both human labor and automation are commonly used. A fabricated product may be called a ''fabrication'', and shops specializing in this type of work are called ''fab shops''. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication. Processes *''Cutting'' is done by sawing, shearing, or chiselling (all with manual and powered variants); ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Breech

Breech may refer to: * Breech (firearms), the opening at the rear of a gun barrel where the cartridge is inserted in a breech-loading weapon * breech, the lower part of a pulley block * breech, the penetration of a boiler where exhaust gases leave it * breech birth, when the baby is born feet or bottom first * breeches, an item of clothing covering the body from the waist down * buttocks, or breech, the lower part of the human abdomen People with the surname * Ernest R. Breech (1897–1978), American businessman, chairman of Ford Motor Company * Jim Breech (born 1956), American football player See also * * Breach (other) Breach, Breached, or The Breach may refer to: Places * Breach, Kent, United Kingdom * Breach, West Sussex, United Kingdom * ''The Breach'', Great South Bay in the State of New York People *Breach (DJ), an Electronic/House music act *Miroslava B ... * Breeching (other) {{disambiguation, surname ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material according to the Fresnel equations). In some materials (such as metals, glasses, black or transparent stones), polishing is also able to reduce diffuse reflection to minimal values. When an unpolished surface is magnified thousands of times, it usually looks like a succession of mountains and valleys. By repeated abrasion, those "mountains" are worn down until they are flat or just small "hills." The process of polishing with abrasives starts with a coarse grain size and gradually proceeds to the finer ones to efficiently flatten the surface imperfections and to obtain optimal results. Mechanical properties The strength of polished products can be higher than their unpolished counterparts owing to the removal of stress concentrations present ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

File (tool)

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.. A rasp is a form of file with distinct, individually cut teeth used for coarsely removing large amounts of material. Files have also been developed with abrasive surfaces, such as natural or synthetic diamond grains or silicon carbide, allowing removal of material that would dull or resist steel files, such as ceramic. History Early filing or rasping has prehistoric roots and grew naturally out of the blending of the twin inspirations of cutting with stone cutting tools (such as hand axes) and abrading using natural abrasives, such as well-suited types of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |