|

Selective Laser Sintering

Selective laser sintering (SLS) is an additive manufacturing (AM) technique that uses a laser as the power and heat source to sinter powdered material (typically nylon or polyamide), aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure. It is similar to selective laser melting; the two are instantiations of the same concept but differ in technical details. SLS (as well as the other mentioned AM techniques) is a relatively new technology that so far has mainly been used for rapid prototyping and for low-volume production of component parts. Production roles are expanding as the commercialization of AM technology improves. History Selective laser sintering (SLS) was developed and patented by Dr. Carl Deckard and academic adviser, Dr. Joe Beaman at the University of Texas at Austin in the mid-1980s, under sponsorship of DARPA. Deckard and Beaman were involved in the resulting start up company DTM, e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Dioxide Laser

The carbon-dioxide laser (CO2 laser) was one of the earliest gas lasers to be developed. It was invented by Kumar Patel of Bell Labs in 1964 and is still one of the most useful types of laser. Carbon-dioxide lasers are the highest-power continuous-wave lasers that are currently available. They are also quite efficient: the ratio of output power to pump power can be as large as 20%. The CO2 laser produces a beam of infrared light with the principal wavelength bands centering on 9.6 and 10.6 micrometers (μm). Amplification The active laser medium (laser gain/ amplification medium) is a gas discharge which is air- or water-cooled, depending on the power being applied. The filling gas within a sealed discharge tube consists of around 10–20% carbon dioxide (), around 10–20% nitrogen (), a few percent hydrogen () and/or xenon (Xe), and the remainder is helium (He). A different mixture is used in a ''flow-through'' laser, where is continuously pumped through it. The specific ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Most thermoplastics have a high molecular weight. The polymer chains associate by intermolecular forces, which weaken rapidly with increased temperature, yielding a viscous liquid. In this state, thermoplastics may be reshaped and are typically used to produce parts by various polymer processing techniques such as injection molding, compression molding, calendering, and extrusion. Thermoplastics differ from thermosetting polymers (or "thermosets"), which form irreversible chemical bonds during the curing process. Thermosets do not melt when heated, but typically decompose and do not reform upon cooling. Above its glass transition temperature and below its melting point, the physical properties of a thermoplastic change drastically without an associated phase change. Some thermoplastics do not fully crystallize ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semi-crystalline Polymer

Crystallization of polymers is a process associated with partial alignment of their molecular chains. These chains fold together and form ordered regions called lamellae, which compose larger spheroidal structures named spherulites. Polymers can crystallize upon cooling from melting, mechanical stretching or solvent evaporation. Crystallization affects optical, mechanical, thermal and chemical properties of the polymer. The degree of crystallinity is estimated by different analytical methods and it typically ranges between 10 and 80%, with crystallized polymers often called "semi-crystalline". The properties of semi-crystalline polymers are determined not only by the degree of crystallinity, but also by the size and orientation of the molecular chains. Crystallization mechanisms Solidification from the melt Polymers are composed of long molecular chains which form irregular, entangled coils in the melt. Some polymers retain such a disordered structure upon freezing and readily c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyaryletherketone

Polyaryletherketone (PAEK) is a family of semi-crystalline thermoplastics with high-temperature stability and high mechanical strength whose molecular backbone contains alternately ketone (R-CO-R) and ether groups (R-O-R). The linking group R between the functional groups consists of a 1,4-substituted aryl group.. Properties PAEK has a continuous operating temperature of and under short-term loads can function up to . When burned it has the least toxic and corrosive fumes. It also has a low heat output when burned, so it qualifies for use in interior aviation applications. It also has good overall chemical resistance.. It has a tensile strength of and a Young's modulus of . Its yield strength is at and at . It does not break in an un-notched Izod impact test.. Chemistry PAEK plastics are characterized by phenylene rings that are linked via oxygen bridges (ether and carbonyl groups (ketone)). The ratio and sequence of ether to ketones mainly affects the glass transition temp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic Elastomer

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastics are in contrast relatively easy to use in manufacturing, for example, by injection moulding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-linking bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties. Types There are six generic classes of commercial TPEs (desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

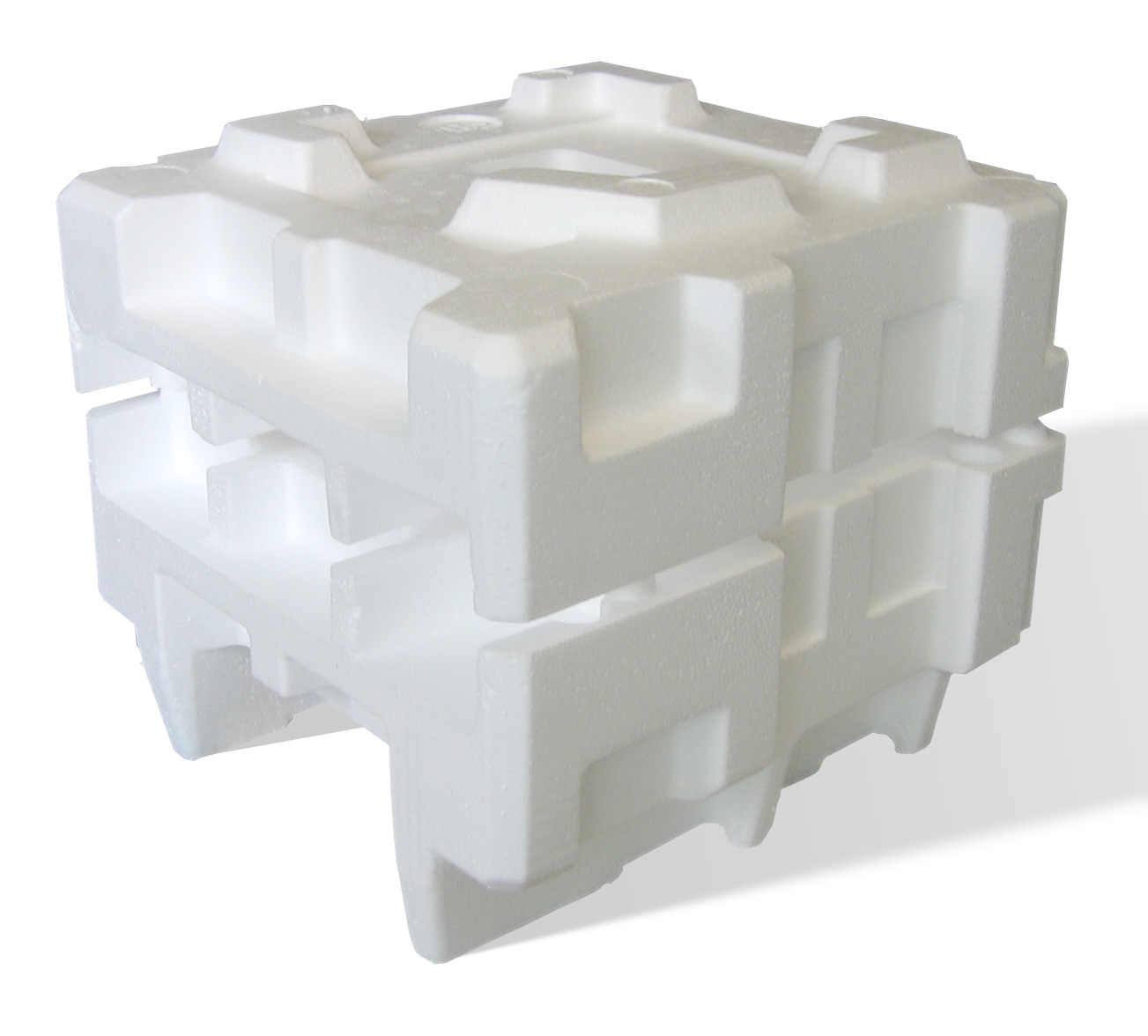

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nesting (process)

In manufacturing industry, nesting refers to the process of laying out cutting patterns to minimize the raw material waste. Examples include manufacturing parts from flat raw material such as sheet metal. Such process can also be applied to additive manufacturing, such as 3D printing. Here the advantages sought can include minimizing tool movement that is not producing product, or maximizing how many pieces can be fabricated in one build session. One difference from nesting of cut pieces is that 3D parts often have a cross section that changes with height, which can cause interference between adjacent parts as they are built up. Process To minimize the amount of scrap raw material produced during cutting, companies use nesting software. It automates the calculation of ideal distribution of the cutting patterns to avoid waste. The process involves the analyses the parts (shapes) to be produced at a particular time. Using algorithms, it then determines how to lay these parts out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulsed Laser

Pulsed operation of lasers refers to any laser not classified as continuous wave, so that the optical power appears in pulses of some duration at some repetition rate. Silfvast, William T. (1996). ''Laser Fundamentals'', Cambridge University Press. This encompasses a wide range of technologies addressing a number of different motivations. Some lasers are pulsed simply because they cannot be run in continuous mode. In other cases the application requires the production of pulses having as large an energy as possible. Since the pulse energy is equal to the average power divided by the repetition rate, this goal can sometimes be satisfied by lowering the rate of pulses so that more energy can be built up in between pulses. In laser ablation for example, a small volume of material at the surface of a work piece can be evaporated if it is heated in a very short time, whereas supplying the energy gradually would allow for the heat to be absorbed into the bulk of the piece, never attaini ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SLS Schematic

SLS may refer to the Space Launch System, a launch vehicle developed by NASA. It may also refer to: Education * Stanford Law School, California, U.S. * Sydney Law School, Australia * Symbiosis Law School, India * Same language subtitling, of TV Places * Sim Lim Square, a shopping centre, Singapore * SLS Las Vegas, a hotel and casino, US Politics * Former ''Samostalna liberalna stranka'' (Independent Liberal Party (Kosovo)) * Former ''Srpska liberalna stranka'' (Serbian Liberal Party) * ''Slovenska ljudska stranka'' (Slovenian People's Party) * ''Slovenská ľudová strana'' (Slovak People's Party, SĽS) * Students for a Libertarian Society, an American student organisation Science and technology * Selective laser sintering, an additive manufacturing technique * Sea level standard conditions * Sodium lauryl sulfate, a surfactant * Static light scattering, a technique to measure molecular weight * Standard linear solid model, of a viscoelastic material * Streptolysin S, a ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of the molten form; some glasses such as volcanic glass are naturally occurring. The most familiar, and historically the oldest, types of manufactured glass are "silicate glasses" based on the chemical compound silica (silicon dioxide, or quartz), the primary constituent of sand. Soda–lime glass, containing around 70% silica, accounts for around 90% of manufactured glass. The term ''glass'', in popular usage, is often used to refer only to this type of material, although silica-free glasses often have desirable properties for applications in modern communications technology. Some objects, such as drinking glasses and eyeglasses, are so commonly made of silicate-based glass that they are simply called by the name of the material. Despite bei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |