|

Supercharging

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a supercharger is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gasses. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and/or increase power outputs. Des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supercharger Animation By Tyroola

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a supercharger is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gasses. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and/or increase power outputs. Des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Type Supercharger

A centrifugal supercharger is a specialized type of supercharger that makes use of centrifugal force in order to increase the manifold air pressure, MAP. An increased MAP allows the engine to burn more fuel, which results in an increased power output. Centrifugal superchargers are generally attached to the front of the engine via a belt-drive or gear-drive from the engine's crankshaft. Types of centrifugal superchargers The centrifugal supercharger is used in many applications including, but not limited to, automotive, truck, marine, aircraft, motorcycles and UTV's. Of these applications, they are most commonly utilized for increasing horsepower in street vehicles and race applications. While the first practical centrifugal compressor was designed in 1899, centrifugal superchargers evolved during World War II with their use in aircraft, where they were frequently paired with their exhaust driven counterpart, the turbosupercharger. This term refers to the fact that turbochargers are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls-Royce Merlin

The Rolls-Royce Merlin is a British liquid-cooled V-12 piston aero engine of 27-litres (1,650 cu in) capacity. Rolls-Royce designed the engine and first ran it in 1933 as a private venture. Initially known as the PV-12, it was later called ''Merlin'' following the company convention of naming its four-stroke piston aero engines after birds of prey. After several modifications, the first production variants of the PV-12 were completed in 1936. The first operational aircraft to enter service using the Merlin were the Fairey Battle, Hawker Hurricane and Supermarine Spitfire. The Merlin remains most closely associated with the Spitfire and Hurricane, although the majority of the production run was for the four-engined Avro Lancaster heavy bomber. A series of rapidly-applied developments, brought about by wartime needs, markedly improved the engine's performance and durability. Starting at 1,000 hp for the first production models, most late war versions produced just ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Wave Supercharger

A pressure wave supercharger (also known as a wave rotor) is a type of supercharger technology that harnesses the pressure waves produced by an internal combustion engine exhaust gas pulses to compress the intake air. Its automotive use is not widespread; the most widely used example is the ''Comprex'', developed by Brown Boveri.A Review of Wave Rotor Technology and its Applications including details of Comprex supercharger Valmet Tractors of Finland were one of the first to use the device when they fitted it to the 411CX engine which powered their 1203 model of 1980. Although it provided a useful increase in performance it was considered too expensive to be incorporated into later models. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sliding Vane

A rotary vane pump is a positive-displacement pump that consists of vanes mounted to a rotor that rotates inside a cavity. In some cases these vanes can have variable length and/or be tensioned to maintain contact with the walls as the pump rotates. It was invented by Charles C. Barnes of Sackville, New Brunswick, who patented it on June 16, 1874. There have been various improvements, including a variable vane pump for gases (1909). They are considered less suitable than other vacuum pumps for high-viscosity and high-pressure fluids, and are complex to operate. They can endure short periods of dry operation, and are considered good for low-viscosity fluids. Type The simplest vane pump has a circular rotor rotating inside a larger circular cavity. The centers of these two circles are offset, causing eccentricity. Vanes and seal on all edges, creating vane chambers that do the pumping work. On the suction side of the pump the vane chambers are increased in volume. These are filled w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo Lag

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a supercharger is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a supercharger is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, |

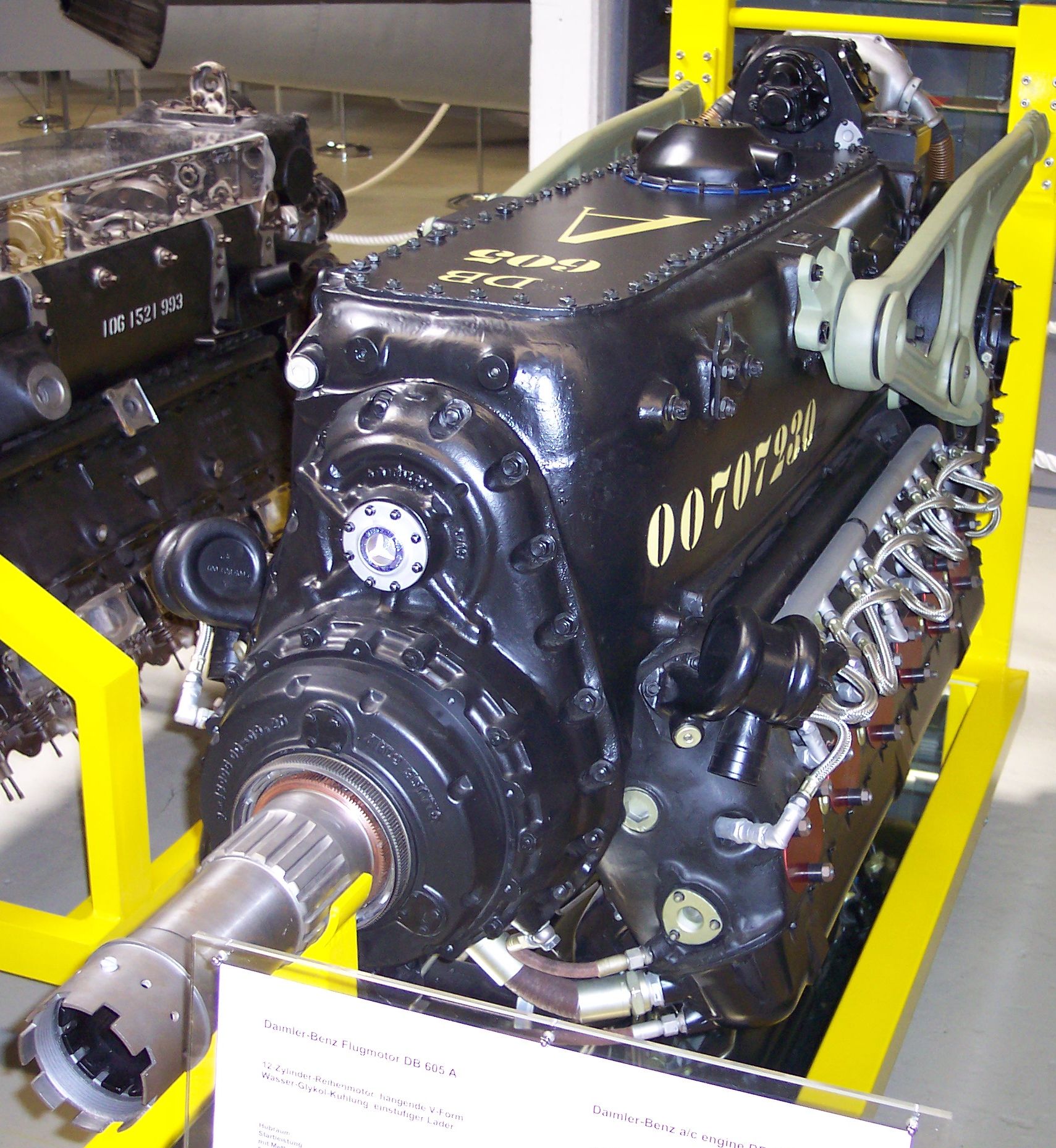

Daimler-Benz DB 605

The Daimler-Benz DB 605 is a German aircraft engine built during World War II. Developed from the DB 601, the DB 605 was used from 1942 to 1945 in the Messerschmitt Bf 109 fighter, and the Bf 110 and Me 210C heavy fighters. The DB 610, a pair of DB 605s geared to turn a single output shaft that replaced the similar DB 606, was used in the A-3 and all A-5 variants of Germany's only operational heavy bomber, the Heinkel He 177A. License-built versions of the DB 605 were used in the Macchi C.205, Fiat G.55, Reggiane 2005 and some other Italian aircraft. It was also used in the Swedish SAAB B 18B and initially in the pusher-design SAAB J 21. Approximately 42,400 DB 605s of all kinds were built. Design and development The primary differences between the 605 and 601 were greater displacement, higher revolutions, higher compression ratio and a more powerful supercharger. Engineers determined that the cylinders could be bored out to a larger diameter without seriously affecting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Supercharger

An electric supercharger is a specific type of supercharger for internal combustion engines that uses an electrically powered forced-air system that contains an electric motor to pressurize the intake air. By pressurizing the air available to the engine intake system, the air becomes more dense, and is matched with more fuel, producing the increased horsepower to the wheels. Power supply for electric superchargers An electric supercharger, if supplied by common stock electric accumulators, runs independent of the engine to which it provides its boost. However, electrical energy consumed is often higher than what a production-line generator (e.g. alternator) of the engine can supply. Larger alternators are therefore fitted to recharge accumulators during the engine run. Efficiency The efficiency of an electric supercharger is curbed by several energy conversion losses (alternator for charging), damp energy while charging the accumulators and the compressor providing boost. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scavenging (engine)

Scavenging is the process of replacing the exhaust gas in a cylinder of an internal combustion engine with the fresh air/fuel mixture (or fresh air, in the case of direct-injection engines) for the next cycle. If scavenging is incomplete, the remaining exhaust gases can cause improper combustion for the next cycle, leading to reduced power output. Scavenging is equally important for both two-stroke and four-stroke engines. Most modern four-stroke engines use crossflow cylinder heads and valve timing overlap to scavenge the cylinders. Modern two-stroke engines use either Schnuerle scavenging (also known as "loop scavenging") or uniflow scavenging. The scavenge or scavenging port refers to that port through which clean air enters the cylinder, the exhaust port through which it leaves. Origins The first engines deliberately designed to encourage scavenging were gas engines built by Crossley Brothers Ltd in the United Kingdom in the early 1890s. These ''Crossley Otto Scavengi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forced Induction

In an internal combustion engine, forced induction is where turbocharging or supercharging is used to increase the density of the intake air. Engines without forced induction are classified as naturally aspirated. Operating principle Overview Forced induction is often used to increase the power output of an engine. This is achieved by compressing the intake air, to increase the mass of the air-fuel mixture present within the combustion chamber. A naturally aspirated engine is limited to a maximum intake air pressure equal to its surrounding atmosphere; however a forced induction engine produces "boost", whereby the air pressure is higher than the surrounding atmosphere. Since the density of air increases with pressure, this allows a greater mass of air to enter the combustion chamber. Theoretically, the vapour power cycle analysis of the second law of thermodynamics would suggest that increasing the mean effective pressure within the combustion chamber would also increase ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary-screw Compressor

A rotary-screw compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. These compressors are common in industrial applications and replace more traditional piston compressors where larger volumes of compressed gas are needed, e.g. for large refrigeration cycles such as chillers, or for compressed air systems to operate air-driven tools such as jackhammers and impact wrenches. For smaller rotor sizes the inherent leakage in the rotors becomes much more significant, leading to this type of mechanism being less suitable for smaller compressors than piston compressors. The screw compressor is identical to the screw pump except that the pockets of trapped material get progressively smaller along the screw, thus compressing the material held within the pockets. Thus the screw of a screw compressor is asymmetrical along its length, while a screw pump is symmetrical all the way. The gas compression process of a rotary ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)