|

Squeeze Casting

Squeeze casting is a casting method that combines die casting and forging. It starts with low-pressure casting, followed by the application of very high pressure as the material cools, producing a high-quality casting. This is often carried out using a hydraulic press as part of the casting apparatus. Squeeze casting was originally created to make stronger metal parts for use in the construction and defense industries. The resulting metal parts created from this process are more resistant to wear and heat and have historically been very expensive to produce. The market for these parts has grown to include the agricultural and automotive industries. History Although several people have been credited with the creation of squeeze casting, the idea of squeeze casting (SC) was first patented in 1819 by Hollinggrak (''27'') and further developed by Chernov in 1878. Together, the team of scientists devised a new way to combine extremely high temperatures and 15,000 pounds per squa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

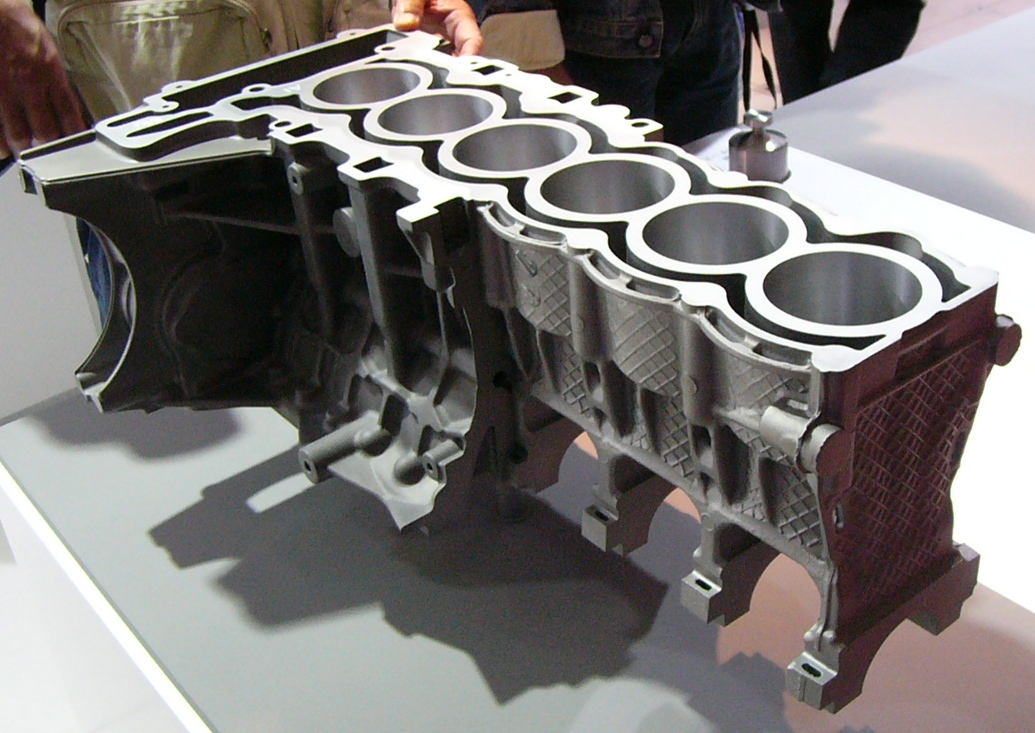

Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process. Die castings are characterized by a very good surfac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by smiths for millennia; the traditional products were kitchenware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanisms and machines wherever a component requires high strength; such forgings usually require further processing (such as machining) to achieve a finished part. Today, forging is a major worldwide industry. History Forging is one of the oldest known me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Press

A hydraulic press is a machine press using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever, and was also known as a Bramah press after the inventor, Joseph Bramah, of England. He invented and was issued a patent on this press in 1795. As Bramah (who is also known for his development of the flush toilet) installed toilets, he studied the existing literature on the motion of fluids and put this knowledge into the development of the press. Main principle The hydraulic press depends on Pascal's principle-the pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with a modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force. Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder. Pascal's law: Pressu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Construction Industry

Construction is a general term meaning the art and science to form objects, systems, or organizations,"Construction" def. 1.a. 1.b. and 1.c. ''Oxford English Dictionary'' Second Edition on CD-ROM (v. 4.0) Oxford University Press 2009 and comes from Latin ''constructio'' (from ''com-'' "together" and ''struere'' "to pile up") and Old French ''construction''. To construct is the verb: the act of building, and the noun is construction: how something is built, the nature of its structure. In its most widely used context, construction covers the processes involved in delivering buildings, infrastructure, industrial facilities and associated activities through to the end of their life. It typically starts with planning, financing, and design, and continues until the asset is built and ready for use; construction also covers repairs and maintenance work, any works to expand, extend and improve the asset, and its eventual demolition, dismantling or decommissioning. The construction i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Defense Industry

The arms industry, also known as the arms trade, is a global industry which manufactures and sells weapons and military technology. It consists of a commercial industry involved in the research and development, engineering, production, and servicing of military material, equipment, and facilities. Arms-producing companies, also referred to as arms dealers, or as the military industry, produce arms for the armed forces of states and for civilians. Departments of government also operate in the arms industry, buying and selling weapons, munitions and other military items. An arsenal is a place where arms and ammunition - whether privately or publicly owned - are made, maintained and repaired, stored, or issued, in any combination. Products of the arms industry include guns, artillery, ammunition, missiles, military aircraft, military vehicles, ships, electronic systems, military communications, night-vision devices, holographic weapon sights, laser rangefinders, laser sights, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Agriculture

Agriculture or farming is the practice of cultivating plants and livestock. Agriculture was the key development in the rise of sedentary human civilization, whereby farming of domesticated species created food surpluses that enabled people to live in cities. The history of agriculture began thousands of years ago. After gathering wild grains beginning at least 105,000 years ago, nascent farmers began to plant them around 11,500 years ago. Sheep, goats, pigs and cattle were domesticated over 10,000 years ago. Plants were independently cultivated in at least 11 regions of the world. Industrial agriculture based on large-scale monoculture in the twentieth century came to dominate agricultural output, though about 2 billion people still depended on subsistence agriculture. The major agricultural products can be broadly grouped into foods, fibers, fuels, and raw materials (such as rubber). Food classes include cereals (grains), vegetables, fruits, cooking oils, meat, milk, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Industry

The automotive industry comprises a wide range of company, companies and organizations involved in the design, Business development, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest industry (economics), industries by revenue (from 16 % such as in France up to 40 % to countries like Slovakia). It is also the industry with the highest spending on research & development per firm. The word ''automotive'' comes from the Greek language, Greek ''autos'' (self), and Latin ''motivus'' (of motion), referring to any form of self-powered vehicle. This term, as proposed by Elmer Ambrose Sperry, Elmer Sperry (1860-1930), first came into use with reference to automobiles in 1898. History The automotive industry began in the 1860s with hundreds of manufacturers that pioneered the Brass Era car, horseless carriage. For many decades, the United States led the world in total automobile production. In 1929, before the Great Depression, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pounds Per Square Inch

The pound per square inch or, more accurately, pound-force per square inch (symbol: lbf/in2; abbreviation: psi) is a unit of pressure or of stress based on avoirdupois units. It is the pressure resulting from a force of one pound-force applied to an area of one square inch. In SI units, 1 psi is approximately equal to 6895 Pa. Pounds per square inch absolute (psia) is used to make it clear that the pressure is relative to a vacuum rather than the ambient atmospheric pressure. Since atmospheric pressure at sea level is around , this will be added to any pressure reading made in air at sea level. The converse is pounds per square inch gauge (psig), indicating that the pressure is relative to atmospheric pressure. For example, a bicycle tire pumped up to 65 psig in a local atmospheric pressure at sea level (14.7 psi) will have a pressure of 79.7 psia (14.7 psi + 65 psi). When gauge pressure is referenced to something other than ambient atmospheric pressure, then the u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Melting Point

The melting point (or, rarely, liquefaction point) of a substance is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depends on pressure and is usually specified at a standard pressure such as 1 atmosphere or 100 kPa. When considered as the temperature of the reverse change from liquid to solid, it is referred to as the freezing point or crystallization point. Because of the ability of substances to supercool, the freezing point can easily appear to be below its actual value. When the "characteristic freezing point" of a substance is determined, in fact, the actual methodology is almost always "the principle of observing the disappearance rather than the formation of ice, that is, the melting point." Examples For most substances, melting and freezing points are approximately equal. For example, the melting point ''and'' freezing point of mercury is . How ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molten Metal

Melting, or fusion, is a physical process that results in the phase transition of a substance from a solid to a liquid. This occurs when the internal energy of the solid increases, typically by the application of heat or pressure, which increases the substance's temperature to the melting point. At the melting point, the ordering of ions or molecules in the solid breaks down to a less ordered state, and the solid "melts" to become a liquid. Substances in the molten state generally have reduced viscosity as the temperature increases. An exception to this principle is the element sulfur, whose viscosity increases in the range of 160 °C to 180 °C due to polymerization. Some organic compounds melt through mesophases, states of partial order between solid and liquid. First order phase transition From a thermodynamics point of view, at the melting point the change in Gibbs free energy ''∆G'' of the substances is zero, but there are non-zero changes in the enthal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Durability

Durability is the ability of a physical product to remain functional, without requiring excessive maintenance or repair, when faced with the challenges of normal operation over its design lifetime. There are several measures of durability in use, including years of life, hours of use, and number of operational cycles. In economics, goods with a long usable life are referred to as durable goods. Requirements for product durability Product durability is predicated by good repairability and regenerability in conjunction with maintenance. Every durable product must be capable of adapting to technical, technological and design developments. This must be accompanied by a willingness on the part of consumers to forgo having the "very latest" version of a product. In the United Kingdom, durability as a characteristic relating to the quality of goods that can be demanded by consumers was not clearly established until an amendment of the Sale of Goods Act 1979 relating to the quality ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |