|

Ready Mixed Concrete

Ready-mix concrete (RMC) is concrete that is manufactured in a batch plant, according to each specific job requirement, then delivered to the job site "ready to use". There are two types with the first being the barrel truck or in–transit mixers. This type of truck delivers concrete in a plastic state to the site. The second is the volumetric concrete mixer. This delivers the ready mix in a dry state and then mixes the concrete on site. However, other sources divide the material into three types: Transit Mix, Central Mix or Shrink Mix concrete. Ready-mix concrete refers to concrete that is specifically manufactured for customers' construction projects, and supplied to the customer on site as a single product. It is a mixture of Portland or other cements, water and aggregates: sand, gravel, or crushed stone. All aggregates should be of a washed type material with limited amounts of fines or dirt and clay. An admixture is often added to improve workability of the concrete ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Self-consolidating Concrete

Self-consolidating concrete or self-compacting concrete (SCC) National Ready Mixed Concrete Association is a mix which has a low , high deformability, good segregation resistance (prevents separation of particles in the mix), and moderate (necessary to ensure uniform suspension of solid particles during transportation, placement (without external co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

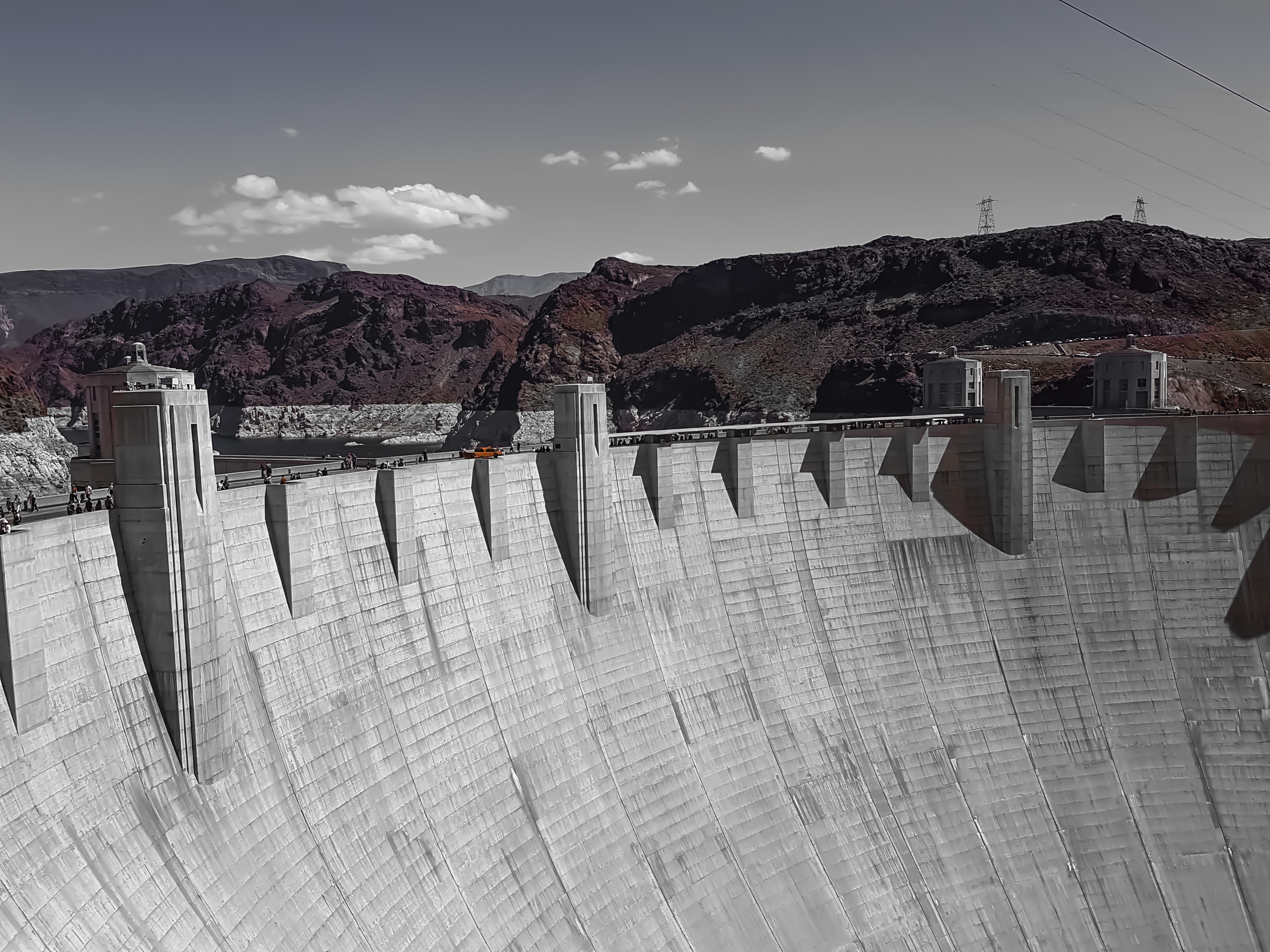

Concrete

Concrete is a composite material composed of fine and coarse aggregate bonded together with a fluid cement (cement paste) that hardens (cures) over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminum combined. Globally, the ready-mix concrete industry, the largest segment of the concrete market, is projected to exceed $600 billion in revenue by 2025. This widespread use results in a number of environmental impacts. Most notably, the production process for cement produces large volumes of greenhouse gas emissions, leading to net 8% of global emissions. Other environmental concerns include widespread illegal sand mining, impacts on the surrounding environment such as increased surface runoff or urban heat island effect, and potential public health implications from toxic ingredients. Significant research and development is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reinforced Concrete

Reinforced concrete (RC), also called reinforced cement concrete (RCC) and ferroconcrete, is a composite material in which concrete's relatively low tensile strength and ductility are compensated for by the inclusion of reinforcement having higher tensile strength or ductility. The reinforcement is usually, though not necessarily, steel bars ( rebar) and is usually embedded passively in the concrete before the concrete sets. However, post-tensioning is also employed as a technique to reinforce the concrete. In terms of volume used annually, it is one of the most common engineering materials. In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion. Description Reinforcing schemes are generally designed to resist tensile stresses in particular regions of the concrete that might cause unacceptable cracking and/or structural failure. Modern reinforced concrete can contain varied reinforcing materials made of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Types Of Concrete

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs. Mix design Modern concrete mix designs can be complex. The choice of a concrete mix depends on the need of the project both in terms of strength and appearance and in relation to local legislation and building codes. The design begins by determining the requirements of the concrete. These requirements take into consideration the weather conditions that the concrete will be exposed to in service, and the required design strength. The compressive strength of a concrete is determined by taking standard molded, standard-cured cylinder samples. Many factors need to be taken into account, from the cost of the various additives and aggregates, to the trade offs between the "slump" for easy mixing and placement and ultimate performance. A mix is then designed using cement (Portland or other cementitious material), coarse and fine aggregates, water and chemical a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inner City

The term ''inner city'' has been used, especially in the United States, as a euphemism for majority-minority lower-income residential districts that often refer to rundown neighborhoods, in a downtown or city centre area. Sociologists sometimes turn the euphemism into a formal designation by applying the term ''inner city'' to such residential areas, rather than to more geographically central commercial districts. The word " downtown" is also used to describe the inner city or city centre – primarily in North America – by English-speakers to refer to a city's commercial, cultural and often the historical, political and geographic heart, and is often contiguous with its central business district. In British English, the term " city centre" is most often used, "''centre-ville''" in French, ''centro storico'' in Italian, ''Stadtzentrum'' in German or ''shìzhōngxīn'' (市中心) in Chinese. The two terms are used interchangeably in Canada. A few US cities, such as Phi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

On-site Concrete Mixer

A concrete mixer (often colloquially called a cement mixer) is a device that homogeneously combines cement, aggregate such as sand or gravel, and water to form concrete. A typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to use the concrete before it hardens. An alternative to a machine is mixing concrete by hand. This is usually done in a wheelbarrow; however, several companies have recently begun to sell modified tarps for this purpose. The concrete mixer was invented by Columbus, Ohio industrialist Gebhardt Jaeger. History One of the first concrete mixers ever was developed in 1900 by T.L. Smith in Milwaukee. The mixer already exhibited the still common basic construction with a tiltable conical drum (as double cone at that time) with blades. 1925, at least two mixers, built 25 years ago, were still ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ground Granulated Blast-furnace Slag

Ground-granulated blast-furnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder. Ground-granulated blast furnace slag is a latent hydraulic binder forming calcium silicate hydrates (C-S-H) after contact with water. It is a strength-enhancing compound improving the durability of concrete. It is a component of metallurgic cement ( in the European norm ). Its main advantage is its slow release of hydration heat allowing to limit the temperature increase in massive concrete components and structures during cement setting and concrete curing, or to cast concrete during hot summer. Production and composition The chemical composition of a slag varies considerably depending on the composition of the raw materials in the iron production process. Silicate and aluminate impurities from the ore and coke are comb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fly Ash

Fly ash, flue ash, coal ash, or pulverised fuel ash (in the UK) plurale tantum: coal combustion residuals (CCRs)is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coal-fired boilers together with the flue gases. Ash that falls to the bottom of the boiler's combustion chamber (commonly called a firebox) is called bottom ash. In modern coal-fired power plants, fly ash is generally captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneys. Together with bottom ash removed from the bottom of the boiler, it is known as coal ash. Depending upon the source and composition of the coal being burned, the components of fly ash vary considerably, but all fly ash includes substantial amounts of silicon dioxide (SiO2) (both amorphous and crystalline), aluminium oxide (Al2O3) and calcium oxide (CaO), the main mineral compounds in coal-bearing rock strata. The u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource. Cements used in construction are usually inorganic, often lime or calcium silicate based, which can be characterized as hydraulic or the less common non-hydraulic, depending on the ability of the cement to set in the presence of water (see hydraulic and non-hydraulic lime plaster). Hydraulic cements (e.g., Portland cement) set and become adhesive through a chemical reaction between the dry ingredients and water. The chemical reaction results in mineral hydrates that are not very water-soluble and so are quite durable in wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concrete Pump

A concrete pump is a machine used for transferring liquid concrete by pumping. There are different types of concrete pumps. A common type of concrete pump for large scale construction projects is known as a boom concrete pump, because it uses a remote-controlled articulating robotic arm (called a ''boom'') to place concrete accurately. It is attached to a truck or a semi-trailer. Boom pumps are capable of pumping at very high volumes and are less labor intensive to operate when compared to line or other types of concrete pumps. The second main type of concrete pump, commonly referred to as a "line pump" or trailer-mounted concrete pump, is either mounted on a truck or placed on a trailer. This pump requires steel or flexible concrete placing hoses to be manually attached to the outlet of the machine and feed the concrete to the place of application. The length of the hoses varies, typical are 10’, 12.5’, 25’ and 50’ long hoses, depending on the diameter. Due to their lo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

EN 206+A1

EN 206+A2 Concrete – Part 1: Specification, performance, production and conformity (formerly EN 206 and EN 206-1 and EN 206+A1) is a European standard elaborated by the CEN/TC 104 "Concrete and related products" technical committee. See also *List of EN standards *European Committee for Standardization * EN 197-1: Cement – Part 1 : Composition, specifications and conformity criteria for common cements * EN 197-2: Cement – Part 2 : Conformity evaluation *EN 1992 In the Eurocode series of European standards (EN) related to construction, '' Eurocode 2: Design of concrete structures'' (abbreviated EN 1992 or, informally, EC 2) specifies technical rules for the design of concrete, reinforced concrete and pre ... Eurocode 2: Design of concrete structures References External links European Committee for Standardization Cement Concrete Construction standards #00206+A1 {{material-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |