|

Process Corners

In semiconductor manufacturing, a process corner is an example of a design-of-experiments (DoE) technique that refers to a variation of fabrication parameters used in applying an integrated circuit design to a semiconductor wafer. Process corners represent the extremes of these parameter variations within which a circuit that has been etched onto the wafer must function correctly. A circuit running on devices fabricated at these process corners may run slower or faster than specified and at lower or higher temperatures and voltages, but if the circuit does not function at all at any of these process extremes the design is considered to have inadequate design margin. To verify the robustness of an integrated circuit design, semiconductor manufacturers will fabricate corner lots, which are groups of wafers that have had process parameters adjusted according to these extremes, and will then test the devices made from these special wafers at varying increments of environmental condi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor

A semiconductor is a material which has an electrical resistivity and conductivity, electrical conductivity value falling between that of a electrical conductor, conductor, such as copper, and an insulator (electricity), insulator, such as glass. Its electrical resistivity and conductivity, resistivity falls as its temperature rises; metals behave in the opposite way. Its conducting properties may be altered in useful ways by introducing impurities ("doping (semiconductor), doping") into the crystal structure. When two differently doped regions exist in the same crystal, a semiconductor junction is created. The behavior of charge carriers, which include electrons, ions, and electron holes, at these junctions is the basis of diodes, transistors, and most modern electronics. Some examples of semiconductors are silicon, germanium, gallium arsenide, and elements near the so-called "metalloid staircase" on the periodic table. After silicon, gallium arsenide is the second-most common s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (integrated Circuit)

A die, in the context of integrated circuits, is a small block of semiconducting material on which a given functional circuit is fabricated. Typically, integrated circuits are produced in large batches on a single wafer of electronic-grade silicon (EGS) or other semiconductor (such as GaAs) through processes such as photolithography. The wafer is cut (diced) into many pieces, each containing one copy of the circuit. Each of these pieces is called a die. There are three commonly used plural forms: ''dice'', ''dies'' and ''die''. To simplify handling and integration onto a printed circuit board, most dies are packaged in various forms. Manufacturing process Most dies are composed of silicon and used for integrated circuits. The process begins with the production of monocrystalline silicon ingots. These ingots are then sliced into disks with a diameter of up to 300 mm. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Simulation

A simulation is the imitation of the operation of a real-world process or system over time. Simulations require the use of Conceptual model, models; the model represents the key characteristics or behaviors of the selected system or process, whereas the simulation represents the evolution of the model over time. Often, computers are used to execute the computer simulation, simulation. Simulation is used in many contexts, such as simulation of technology for performance tuning or optimizing, safety engineering, testing, training, education, and video games. Simulation is also used with scientific modelling of natural systems or human systems to gain insight into their functioning, as in economics. Simulation can be used to show the eventual real effects of alternative conditions and courses of action. Simulation is also used when the real system cannot be engaged, because it may not be accessible, or it may be dangerous or unacceptable to engage, or it is being designed bu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BSIM

BSIM (Berkeley Short-channel IGFET Model) refers to a family of MOSFET transistor models for integrated circuit design. It also refers to the BSIM group located in the Department of Electrical Engineering and Computer Sciences (EECS) at the University of California, Berkeley, that develops these models. Accurate transistor models are needed for electronic circuit simulation, which in turn is needed for integrated circuit design. As the devices become smaller each process generation (see Moore's law), new models are needed to accurately reflect the transistor's behavior. Commercial and industrial analog simulators (such as SPICE) have added many other device models as technology advanced and earlier models became inaccurate. To attempt standardization of these models so that a set of model parameters may be used in different simulators, an industry working group was formed, the Compact Model Coalition, to choose, maintain, and promote the use of standard models. BSIM models, develop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

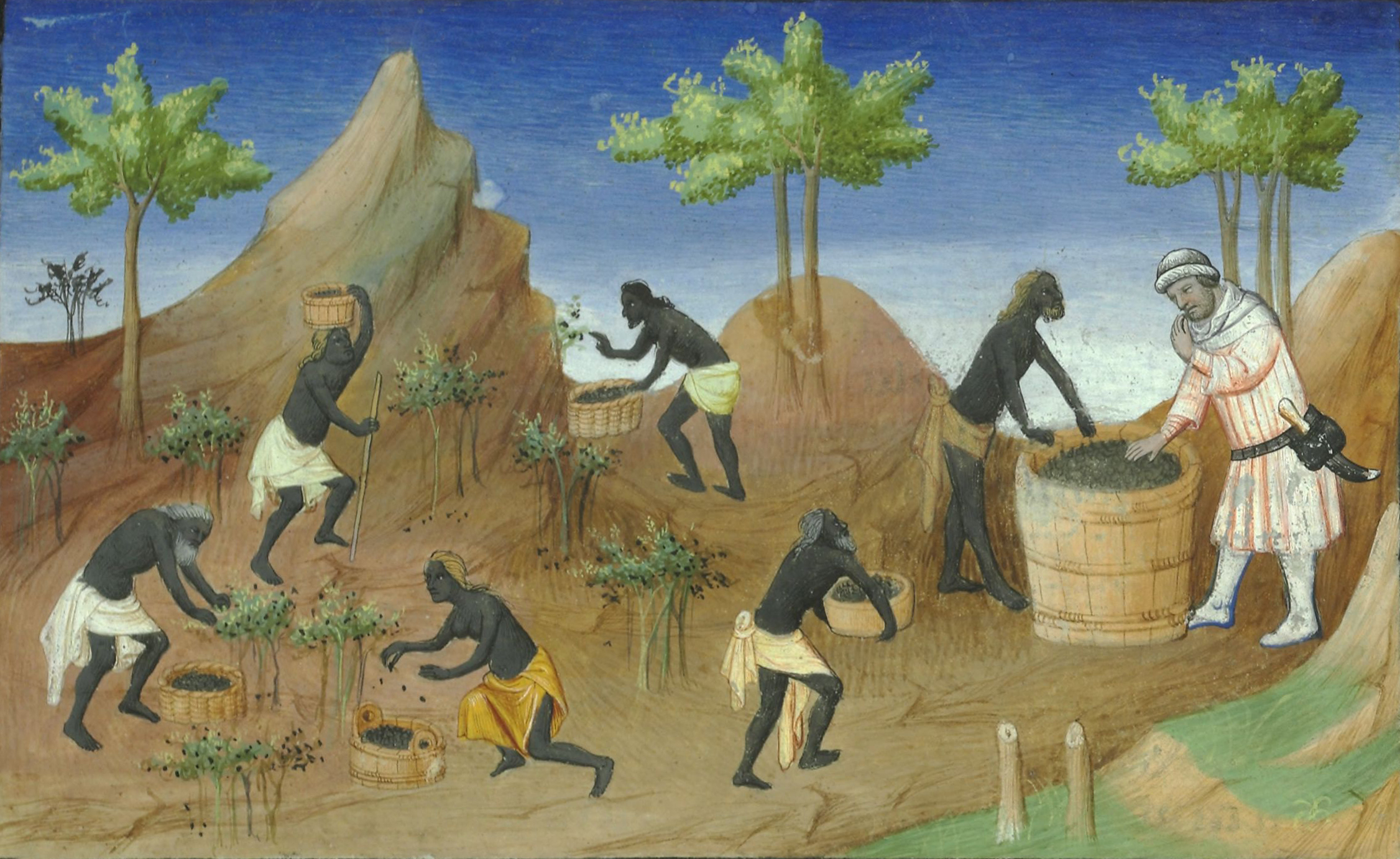

SPICE

A spice is a seed, fruit, root, bark, or other plant substance primarily used for flavoring or coloring food. Spices are distinguished from herbs, which are the leaves, flowers, or stems of plants used for flavoring or as a garnish. Spices are sometimes used in medicine, religious rituals, cosmetics or perfume production. For example, vanilla is commonly used as an ingredient in fragrance manufacturing. A spice may be available in several forms: fresh, whole dried, or pre-ground dried. Generally, spices are dried. Spices may be ground into a powder for convenience. A whole dried spice has the longest shelf life, so it can be purchased and stored in larger amounts, making it cheaper on a per-serving basis. A fresh spice, such as ginger, is usually more flavorful than its dried form, but fresh spices are more expensive and have a much shorter shelf life. Some spices are not always available either fresh or whole, for example turmeric, and often must be purchased in ground form. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

90nm

The 90 nm process refers to the level of MOSFET (CMOS) fabrication process technology that was commercialized by the 2003–2005 timeframe, by leading semiconductor companies like Toshiba, Sony, Samsung, IBM, Intel, Fujitsu, TSMC, Elpida, AMD, Infineon, Texas Instruments and Micron Technology. The origin of the 90 nm value is historical, it reflects a trend of 70% scaling every 2–3 years. The naming is formally determined by the International Technology Roadmap for Semiconductors (ITRS). The 193 nm wavelength was introduced by many (but not all) companies for lithography of critical layers mainly during the 90 nm node. Yield issues associated with this transition (due to the use of new photoresists) were reflected in the high costs associated with this transition. Even more significantly, the 300 mm wafer size became mainstream at the 90 nm node. The previous wafer size was 200 mm diameter. History A 90nm silicon MOSFET was fabricated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die Shrink

The term die shrink (sometimes optical shrink or process shrink) refers to the scaling of metal-oxide-semiconductor (MOS) devices. The act of shrinking a die is to create a somewhat identical circuit using a more advanced fabrication process, usually involving an advance of lithographic nodes. This reduces overall costs for a chip company, as the absence of major architectural changes to the processor lowers research and development costs while at the same time allowing more processor dies to be manufactured on the same piece of silicon wafer, resulting in less cost per product sold. Details Die shrinks are the key to improving price/performance at semiconductor companies such as Samsung, Intel, TSMC, and SK Hynix, and fabless manufacturers such as AMD (including the former ATI), NVIDIA and MediaTek. Examples in the 2000s include the downscaling of the PlayStation 2's Emotion Engine processor from Sony and Toshiba (from 180 nm CMOS in 2000 to 90 nm CMOS in 2003), t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Latch (electronics)

In electronics, a flip-flop or latch is a electronic circuit, circuit that has two stable states and can be used to store state information – a bistable multivibrator. The circuit can be made to change state by signals applied to one or more control inputs and will have one or two outputs. It is the basic storage element in sequential logic. Flip-flops and latches are fundamental building blocks of digital electronics systems used in computers, communications, and many other types of systems. Flip-flops and latches are used as data storage elements. A flip-flop is a device which stores a single ''bit'' (binary digit) of data; one of its two states represents a "one" and the other represents a "zero". Such data storage can be used for storage of ''state (computer science), state'', and such a circuit is described as sequential logic in electronics. When used in a finite-state machine, the output and next state depend not only on its current input, but also on its current state ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Binning

Product binning is the categorizing of finished products based on their characteristics. Any mining, harvesting, or manufacturing process will yield products spanning a range of quality and desirability in the marketplace. Binning allows differing quality products to be priced appropriately for various uses and markets. Economic and legal theory Product binning and grading allows a degree of price discrimination which may be easier to defend legally, since it can be based on real or perceived differences in product quality. In order to undergo binning, manufactured products require testing, usually performed by machines in bulk. Binning allows large variances in performance to be condensed into a smaller number of marketed designations. This ensures coherency in the marketplace, with tiers of performance clearly delineated. The immediate result of this practice is that, for legal and reputational reasons, products sold under a certain designation must meet that designation at a ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carrier Mobility

In solid-state physics, the electron mobility characterises how quickly an electron can move through a metal or semiconductor when pulled by an electric field. There is an analogous quantity for holes, called hole mobility. The term carrier mobility refers in general to both electron and hole mobility. Electron and hole mobility are special cases of electrical mobility of charged particles in a fluid under an applied electric field. When an electric field ''E'' is applied across a piece of material, the electrons respond by moving with an average velocity called the drift velocity, v_d. Then the electron mobility ''μ'' is defined as v_d = \mu E. Electron mobility is almost always specified in units of cm2/( V⋅ s). This is different from the SI unit of mobility, m2/( V⋅ s). They are related by 1 m2/(V⋅s) = 104 cm2/(V⋅s). Conductivity is proportional to the product of mobility and carrier concentration. For example, the same conductivity could come from a small nu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PMOS Logic

PMOS or pMOS logic (from p-channel metal–oxide–semiconductor) is a family of digital circuits based on p-channel, enhancement mode metal–oxide–semiconductor field-effect transistors (MOSFETs). In the late 1960s and early 1970s, PMOS logic was the dominant semiconductor technology for large-scale integrated circuits before being superseded by NMOS and CMOS devices. History and application Mohamed Atalla and Dawon Kahng manufactured the first working MOSFET at Bell Labs in 1959. They fabricated both PMOS and NMOS devices but only the PMOS devices were working. It would be more than a decade before contaminants in the manufacturing process (particularly sodium) could be managed well enough to manufacture practical NMOS devices. Compared to the bipolar junction transistor, the only other device available at the time for use in an integrated circuit, the MOSFET offers a number of advantages: *Given semiconductor device fabrication processes of similar precision, a MO ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

NMOS Logic

N-type metal-oxide-semiconductor logic uses n-type (-) MOSFETs (metal-oxide-semiconductor field-effect transistors) to implement logic gates and other digital circuits. These nMOS transistors operate by creating an inversion layer in a p-type transistor body. This inversion layer, called the n-channel, can conduct electrons between n-type "source" and "drain" terminals. The n-channel is created by applying voltage to the third terminal, called the gate. Like other MOSFETs, nMOS transistors have four modes of operation: cut-off (or subthreshold), triode, saturation (sometimes called active), and velocity saturation. For many years, NMOS circuits were much faster than comparable PMOS and CMOS circuits, which had to use much slower p-channel transistors. It was also easier to manufacture NMOS than CMOS, as the latter has to implement p-channel transistors in special n-wells on the p-substrate. The major drawback with NMOS (and most other logic families) is that a DC current mus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |