|

Plastic Bending

Plastic bending is a nonlinear behavior particular to members made of ductile materials that frequently achieve much greater ultimate bending strength than indicated by a linear elastic bending analysis. In both the plastic and elastic bending analyses of a straight beam, it is assumed that the strain distribution is linear about the neutral axis (plane sections remain plane). In an elastic analysis this assumption leads to a linear stress distribution but in a plastic analysis the resulting stress distribution is nonlinear and is dependent on the beam’s material. The limiting plastic bending strength M_r (see Plastic moment) can generally be thought of as an upper limit to a beam’s load–carrying capability as it only represents the strength at a particular cross–section and not the load–carrying capability of the overall beam. A beam may fail due to global or local instability before M_r is reached at any point on its length. Therefore, beams should also be checked f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Bending Stress Distribution Of A Beam

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to its widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives. 9.2 billion tonnes of plastic are estimated to have been made between 1950 and 2017. More than half this plastic has been produced since 2004. In 2020, 400 million tonnes of plastic were produced. If global trends on plastic demand continue, it is estimated that by 2050 annual global plastic production will reach over 1,10 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Moment

In structural engineering, the plastic moment (Mp) is a property of a structural section. It is defined as the moment at which the entire cross section has reached its yield stress. This is theoretically the maximum bending moment that the section can resist – when this point is reached a plastic hinge is formed and any load beyond this point will result in theoretically infinite plastic deformation.{{Cite book, title=STRUCTURAL AND STRESS ANALYSIS, author=MEGSON, T. H. G., date=2019, publisher=BUTTERWORTH-HEINEMANN LTD, isbn=0081025866, pages=236, oclc=1048935955 In practice most materials are work-hardened resulting in increased stiffness and moment resistance until the material fails. This is of little significance in structural mechanics as the deflection prior to this occurring is considered to be an earlier failure point in the member. In general, the method to calculate M_p first requires calculation of the plastic section modulus Z_P and then to substitute this into the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress (physics)

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like Tension (physics), tension or Compression (physics), compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while deformation (mechanics)#Strain, strain is the measure of the deformation of the material. For example, when a solid vertic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Neutral Axis

The neutral axis is an axis in the cross section of a beam (a member resisting bending) or shaft along which there are no longitudinal stresses or strains. If the section is symmetric, isotropic and is not curved before a bend occurs, then the neutral axis is at the geometric centroid. All fibers on one side of the neutral axis are in a state of tension, while those on the opposite side are in compression. Since the beam is undergoing uniform bending, a plane on the beam remains plane. That is: \gamma_=\gamma_=\tau_=\tau_=0 Where \gamma is the shear strain and \tau is the shear stress There is a compressive (negative) strain at the top of the beam, and a tensile (positive) strain at the bottom of the beam. Therefore by the Intermediate Value Theorem, there must be some point in between the top and the bottom that has no strain, since the strain in a beam is a continuous function. Let L be the original length of the beam (span) ε(y) is the strain as a function of coordinate on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Hinge

In the structural engineering beam theory, the term "plastic hinge" is used to describe the deformation of a section of a beam where plastic bending occurs. In earthquake engineering plastic hinge is also a type of energy damping device allowing plastic rotation eformationof an otherwise rigid column connection. Plastic behaviour In plastic limit analysis of structural members subjected to bending, it is assumed that an abrupt transition from elastic to ideally plastic behaviour occurs at a certain value of moment, known as plastic moment (Mp). Member behaviour between Myp and Mp is considered to be elastic. When Mp is reached, a plastic hinge is formed in the member. In contrast to a friction Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. There are several types of friction: *Dry friction is a force that opposes the relative lateral motion of t ...less hinge permitting free rotation, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

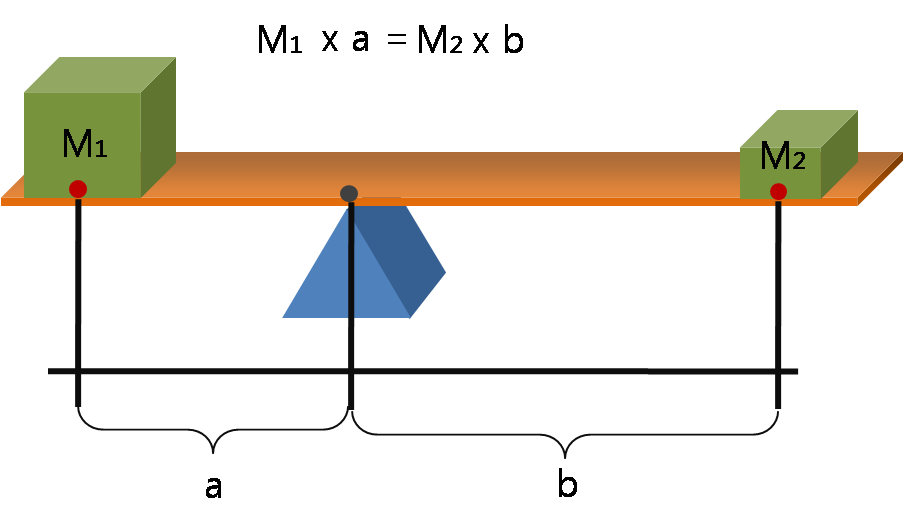

Moment (physics)

In physics, a moment is a mathematical expression involving the product of a distance and physical quantity. Moments are usually defined with respect to a fixed reference point and refer to physical quantities located some distance from the reference point. In this way, the moment accounts for the quantity's location or arrangement. For example, the moment of force, often called torque, is the product of a force on an object and the distance from the reference point to the object. In principle, any physical quantity can be multiplied by a distance to produce a moment. Commonly used quantities include forces, masses, and electric charge distributions. Elaboration In its most basic form, a moment is the product of the distance to a point, raised to a power, and a physical quantity (such as force or electrical charge) at that point: : \mu_n = r^n\,Q, where Q is the physical quantity such as a force applied at a point, or a point charge, or a point mass, etc. If the quantity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Area Integral

In mathematics (specifically multivariable calculus), a multiple integral is a definite integral of a function of several real variables, for instance, or . Integrals of a function of two variables over a region in \mathbb^2 (the real-number plane) are called double integrals, and integrals of a function of three variables over a region in \mathbb^3 (real-number 3D space) are called triple integrals. For multiple integrals of a single-variable function, see the Cauchy formula for repeated integration. Introduction Just as the definite integral of a positive function of one variable represents the area of the region between the graph of the function and the -axis, the double integral of a positive function of two variables represents the volume of the region between the surface defined by the function (on the three-dimensional Cartesian plane where ) and the plane which contains its domain. If there are more variables, a multiple integral will yield hypervolumes of multidim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strength Of Materials

The field of strength of materials, also called mechanics of materials, typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's modulus, and Poisson's ratio. In addition, the mechanical element's macroscopic properties (geometric properties) such as its length, width, thickness, boundary constraints and abrupt changes in geometry such as holes are considered. The theory began with the consideration of the behavior of one and two dimensional members of structures, whose states of stress can be approximated as two dimensional, and was then generalized to three dimensions to develop a more complete theory of the elastic and plastic behavior of materials. An important founding pion ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strength Of Materials

The field of strength of materials, also called mechanics of materials, typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's modulus, and Poisson's ratio. In addition, the mechanical element's macroscopic properties (geometric properties) such as its length, width, thickness, boundary constraints and abrupt changes in geometry such as holes are considered. The theory began with the consideration of the behavior of one and two dimensional members of structures, whose states of stress can be approximated as two dimensional, and was then generalized to three dimensions to develop a more complete theory of the elastic and plastic behavior of materials. An important founding pion ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

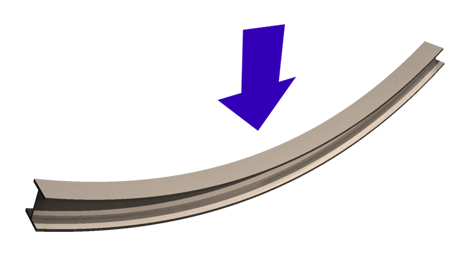

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends and loa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stephen Timoshenko

Stepan Prokofyevich Timoshenko (russian: Степан Прокофьевич Тимошенко, p=sʲtʲɪˈpan prɐˈkofʲjɪvʲɪtɕ tʲɪmɐˈʂɛnkə; uk, Степан Прокопович Тимошенко, Stepan Prokopovych Tymoshenko; – May 29, 1972), later known as Stephen Timoshenko, was a Russian Imperial and later, an AmericanStephen Timoshenko on NNDB and academician of descent. He is considered to be the father of modern |