|

Pipe Threader

Taps and dies are tools used to create screw threads, which is called threading. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called ''chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use chasers on spark plug th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool And Die Maker

Tool and die makers are highly skilled crafters working in the manufacturing, manufacturing industries. Variations on the name include tool maker, toolmaker, die maker, diemaker, Moldmaker, mold maker, moldmaker or tool jig and die-maker depending on which area of concentration or industry an individual works in. Tool and die makers work primarily in toolroom environments—sometimes literally in one room but more often in an environment with flexible, semipermeable boundaries from production work. They are skilled artisans (craft production, craftspeople) who typically learn their trade through a combination of academic coursework and with substantial period of on-the-job training that is functionally an apprenticeship. They make Jig (tool), jigs, Fixture (tool), fixtures, die (manufacturing), dies, molding (process), molds, machine tools, cutting tool (machining), cutting tools, gauge (instrument), gauges, and other tools used in manufacturing processes. Divisions The main divis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

File (tool)

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.. A rasp is a form of file with distinct, individually cut teeth used for coarsely removing large amounts of material. Files have also been developed with abrasive surfaces, such as natural or synthetic diamond grains or silicon carbide, allowing removal of material that would dull or resist steel files, such as ceramic. History Early filing or rasping has prehistoric roots and grew naturally out of the blending of the twin inspirations of cutting with stone cutting tools (such as hand axes) and abrading using natural abrasives, such as well-suited types of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machinist

A machinist is a tradesperson or trained professional who not only operates machine tools, but also has the knowledge of tooling and materials required to create set ups on machine tools such as milling machines, grinders, lathes, and drilling machines. A competent machinist should have a well-developed mechanical aptitude, the ability to correctly use precision measuring instruments, and a working knowledge of the proper speeds and feeds required for successfully utilizing the various work and tool materials commonly used in most machining operations. Nature of work Mass-produced parts of machines are more common today, but still require machinists and millwrights to calibrate and install machine parts to manufacture other parts. In many parts of the economy, however, custom-made parts are required for various uses. A machinist may work on manufacturing something simple like a motorcycle frame part, a piece of an internal combustion motor, or something extraordinarily complex, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kennametal

Kennametal is an American supplier of tooling and industrial materials founded in 1938 by Philip M. McKenna in the Latrobe, Pennsylvania area. Production Kennametal products: *Blades, disks, skins, fuel control systems, and landing gear for the aerospace industry *Synthetic fertilizers for agriculture *Camshafts, crankshafts, cylinder heads, rotors, calipers and differentials for automobiles *Roofing and abrasives for home construction *Asphalt, stabilization tools, and tunneling equipment for road construction *Woodworking tools * Machining industries: ** Machine tools: Machining centers, turning centers (CNC lathes), automatic lathes (screw machines) ** Tooling for machine tools: *** Indexable toolholders, collets *** fixtures *** cutting tools (via Products Group, a consolidation of various brands in this industry): inserts, tool bits, milling cutters, taps and dies, metal sawing cutters and tooling *Mining equipment *Abrasives and flow control for the oil industr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

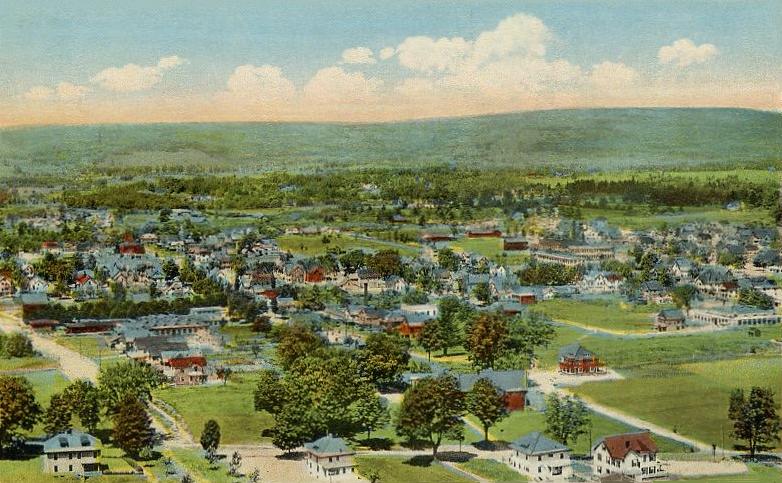

Greenfield, Massachusetts

Greenfield is a city in and the county seat of Franklin County, Massachusetts, United States. Greenfield was first settled in 1686. The population was 17,768 at the 2020 census. Greenfield is home to Greenfield Community College, the Pioneer Valley Symphony Orchestra, and the Franklin County Fair. The city has a Main Street Historic District containing fine examples of Federal, Greek Revival, and Victorian architecture. Greenfield is part of the Springfield, Massachusetts, Metropolitan Statistical Area. History Pocumtuck Indians first settled and originally inhabited the Greenfield area. Native American artifacts found in the area have been dated between 7,000 and 9,000 years BCE. The Pocumtucks planted field crops and fished local rivers. Some sources claim that they were wiped out by the Mohawks in 1664 and that the land was left unoccupied. Other sources show that the Pocumtucks joined the Wampanoag chief Metacom in August 1675 in the fight against English encroachment, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ''straight'' thread and the latter called a ''tapered'' thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its ''lead'', which is the linear distance the screw travels in one revolution. In most applications, the lead of a screw thread is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied, as long as no external rotational force is present. This characteristic is essential to the vast majority of its uses. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast thro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Threading (manufacturing)

In manufacturing, threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element. There are many methods of generating threads, including subtractive methods (many kinds of thread cutting and grinding, as detailed below); deformative or transformative methods (rolling and forming; molding and casting); additive methods (such as 3D printing); or combinations thereof. Overview of methods (comparison, selection, etc.) There are various methods for generating screw threads. The method for any one application is chosen based on constraints—time, money, degree of precision needed (or not needed), what equipment is already available, what equipment purchases could be justified based on resulting unit price of the threaded part (which depends on how many parts are planned), etc. In general, certain thread-generating processes tend to fall along certain portions of the spectrum from toolroom-made parts to mass-produced parts ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |