|

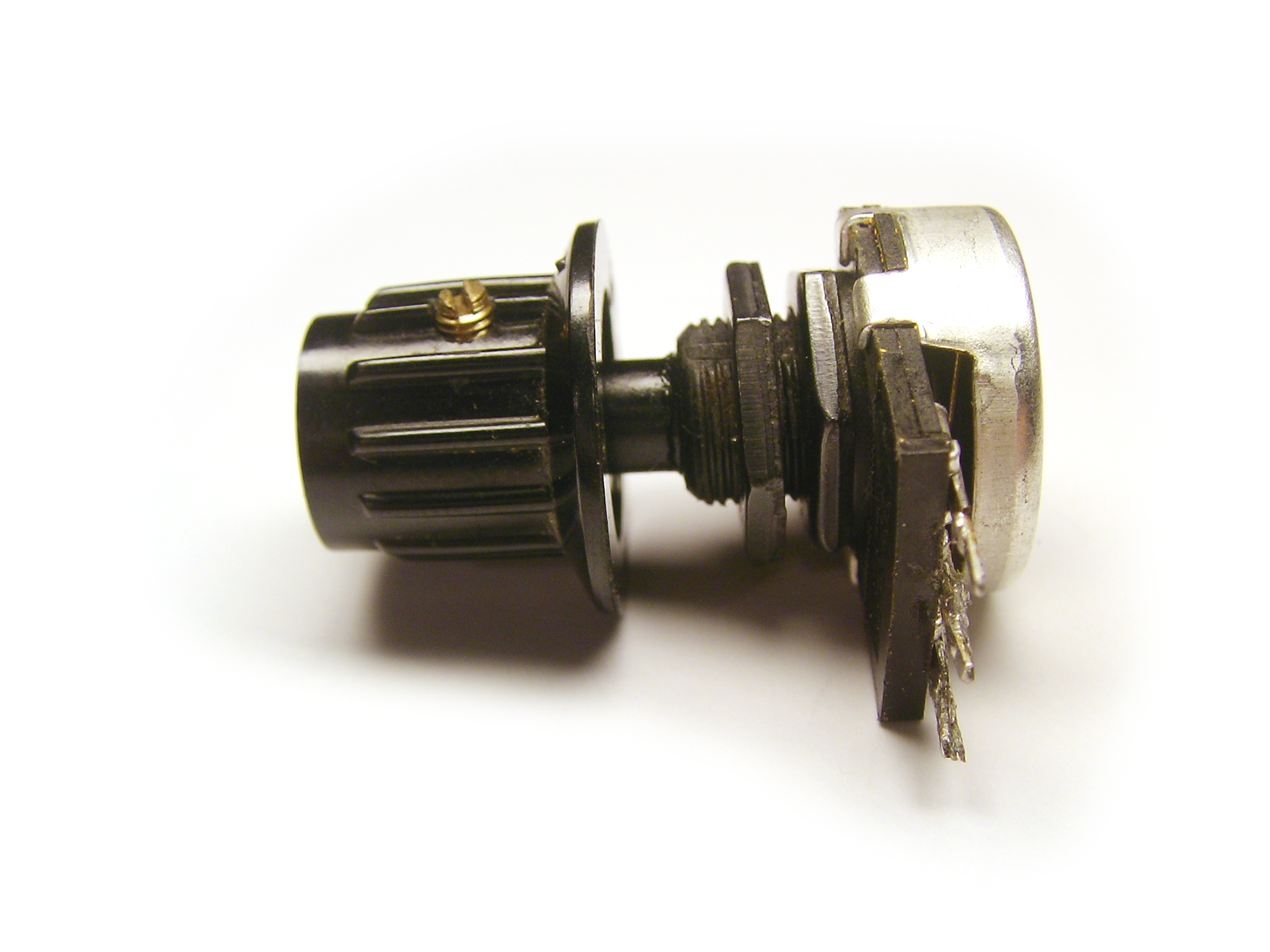

Pillow Block Bearing

A pillow block bearing (or plummer block) is a pedestal used to provide support for a rotating shaft with the help of compatible bearings and various accessories. The assembly consists of a mounting block which houses a bearing. The block is mounted to a foundation and a shaft is inserted allowing the inner part of the bearing / shaft to rotate. The inside of the bearing is typically larger than the shaft to ensure a tight fit. Set screws, locking collars, or set collars are commonly used to secure the shaft. Housing material for a pillow block is typically made of cast iron or cast steel. Selection A pillow block usually refers to a housing with an included anti-friction bearing, wherein the mounted shaft is in a parallel plane to the mounting surface, and perpendicular to the center line of the mounting holes, as contrasted with various types of flange blocks or flange units. A pillow block may contain a bearing with one of several types of rolling elements, including ball, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may ''prevent'' a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the ''plain bearing'', consists of a shaft rotating in a hole. Lubrication is used to reduce friction. In the ''ball bearing'' and ''roller bearing'', to reduce sliding ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Set Screw

In American English, a set screw is a screw that is used to secure an object, by pressure and/or friction, within or against another object, such as fixing a pulley or gear to a shaft. A set screw is normally used without a nut (which distinguishes it from a bolt), being screwed instead in a threaded hole drilled in only one of the two objects to be secured. A set screw is often headless and threaded along its entire length, so that it will sit entirely inside that hole; in which case it may be called a grub screw or blind screw. Once fully and firmly screwed into the first object, the projecting tip of the set screw presses hard against the second object, acting like a clamp. The second object may have a machined detent (recess) to ensure that it cannot slide under the tip of the screw. On a shaft, this may be simply a flattened area. A set screw may have any type of drive, such as hex or square head, slot, or recessed --- cross (Phillips), hex (Allen), star (Torx), or sq ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Steel

Steel casting is a specialized form of casting involving various types of steel cast to either final/net or near-net shape. Steel castings are used when iron castings cannot deliver enough strength or shock resistance.Oberg, p. 1332 Examples of items that are steel castings include: hydroelectric turbine wheels, forging presses, gears, railroad truck frames, valve bodies, pump casings, mining machinery, marine equipment, turbocharger turbines and engine cylinder blocks. Steel castings are categorized into two general groups: carbon steels and alloy steels. Steel castability Steel is more difficult to cast than iron. It has a higher melting point and greater shrinkage rate, which requires consideration during mold design. Risers should be given more capacity to draw from as the metal cools and shrinks. Attention should be paid to the thickness of mold cavities, as thinner areas will cool quicker than thicker areas, which can create internal stress points that can lead t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

International Organization For Standardization

The International Organization for Standardization (ISO ) is an international standard development organization composed of representatives from the national standards organizations of member countries. Membership requirements are given in Article 3 of the ISO Statutes. ISO was founded on 23 February 1947, and (as of November 2022) it has published over 24,500 international standards covering almost all aspects of technology and manufacturing. It has 809 Technical committees and sub committees to take care of standards development. The organization develops and publishes standardization in all technical and nontechnical fields other than electrical and electronic engineering, which is handled by the IEC.Editors of Encyclopedia Britannica. 3 June 2021.International Organization for Standardization" ''Encyclopedia Britannica''. Retrieved 2022-04-26. It is headquartered in Geneva, Switzerland, and works in 167 countries . The three official languages of the ISO are English, Fren ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing Surface

A bearing surface in mechanical engineering is the area of contact between two objects. It usually is used in reference to bolted joints and bearings, but can be applied to a wide variety of engineering applications. On a screw the bearing area loosely refers to the underside of the head. Strictly speaking, the bearing area refers to the area of the screw head that directly bears on the part being fastened. For a cylindrical bearing it is the projected area perpendicular to the applied force. On a spring the bearing area refers to the amount of area on the top or bottom surface of the spring in contact with the constraining part.. The ways of machine tools, such as dovetail slides, box ways, prismatic ways, and other types of machine slides are also bearing surfaces. See also *Babbitt, an alloy that covers a bearing surface *Bridge bearing * Pillow block bearing * Plain bearing A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |