|

Photo-oxidation

In polymer chemistry photo-oxidation (sometimes: oxidative photodegradation) is the degradation of a polymer surface due to the combined action of light and oxygen. It is the most significant factor in the weathering of plastics. Photo-oxidation causes the polymer chains to break (chain scission), resulting in the material becoming increasingly brittle. This leads to mechanical failure and, at an advanced stage, the formation of microplastics. In textiles the process is called phototendering. Technologies have been developed to both accelerate and inhibit this process. For example, plastic building components like doors, window frames and gutters are expected to last for decades, requiring the use of advanced UV-polymer stabilizers. Conversely, single-use plastics can be treated with biodegradable additives to accelerate their fragmentation. Many pigments and dyes can similarly have effects due to their ability to absorb UV-energy. Susceptible polymers Susceptibility to pho ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Stabilizers

Polymer stabilizers (British: polymer stabilisers) are chemical additives which may be added to polymeric materials, such as plastics and rubbers, to inhibit or retard their degradation. Common polymer degradation processes include oxidation, UV degradation, UV-damage, Thermal degradation of polymers, thermal degradation, ozonolysis, combinations thereof such as photo-oxidation of polymers, photo-oxidation, as well as reactions with catalyst residues, dyes, or impurities. All of these degrade the polymer at a chemical level, via chain scission, uncontrolled recombination and cross-linking, which adversely affects many key properties such as strength, malleability, appearance and colour. Stabilizers are used at all stages of the polymer life-cycle. They allow plastic items to be produced faster and with fewer defects, extend their useful lifespan, and facilitate their recycling. However they also continue to stabilise waste plastic, causing it to remain in the environment for longer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Degradation

Polymer degradation is the reduction in the physical properties of a polymer, such as strength, caused by changes in its chemical composition. Polymers and particularly plastics are subject to degradation at all stages of their product life cycle, including during their initial processing, use, disposal into the environment and recycling. The rate of this degradation varies significantly; biodegradation can take decades, whereas some industrial processes can completely decompose a polymer in hours. Technologies have been developed to both inhibit or promote degradation. For instance, polymer stabilizers ensure plastic items are produced with the desired properties, extend their useful lifespans, and facilitate their recycling. Conversely, biodegradable additives accelerate the degradation of plastic waste by improving its biodegradability. Some forms of plastic recycling can involve the complete degradation of a polymer back into monomers or other chemicals. In general, the effec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biodegradable Additives

Biodegradable additives are additives that enhance the biodegradation of polymers by allowing microorganisms to utilize the carbon within the polymer chain as a source of energy. Biodegradable additives attract microorganisms to the polymer through quorum sensing after biofilm creation on the plastic product. Additives are generally in masterbatch formation that use carrier resins such as polyethylene (PE), polypropylene (PP), polystyrene (PS) or polyethylene terephthalate (PET). Most common synthetic plastics are not biodegradable, and both chemical and physical properties of plastics play important roles in the process of plastic degradation. The addition of biodegradable additives can influence the mechanism of plastic degradation by changing the chemical and physical properties of plastics to increase the rate of degradation. Biodegradable additives can convert the plastic degradation process to one of biodegradation. Instead of being degraded simply by environmental factors ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

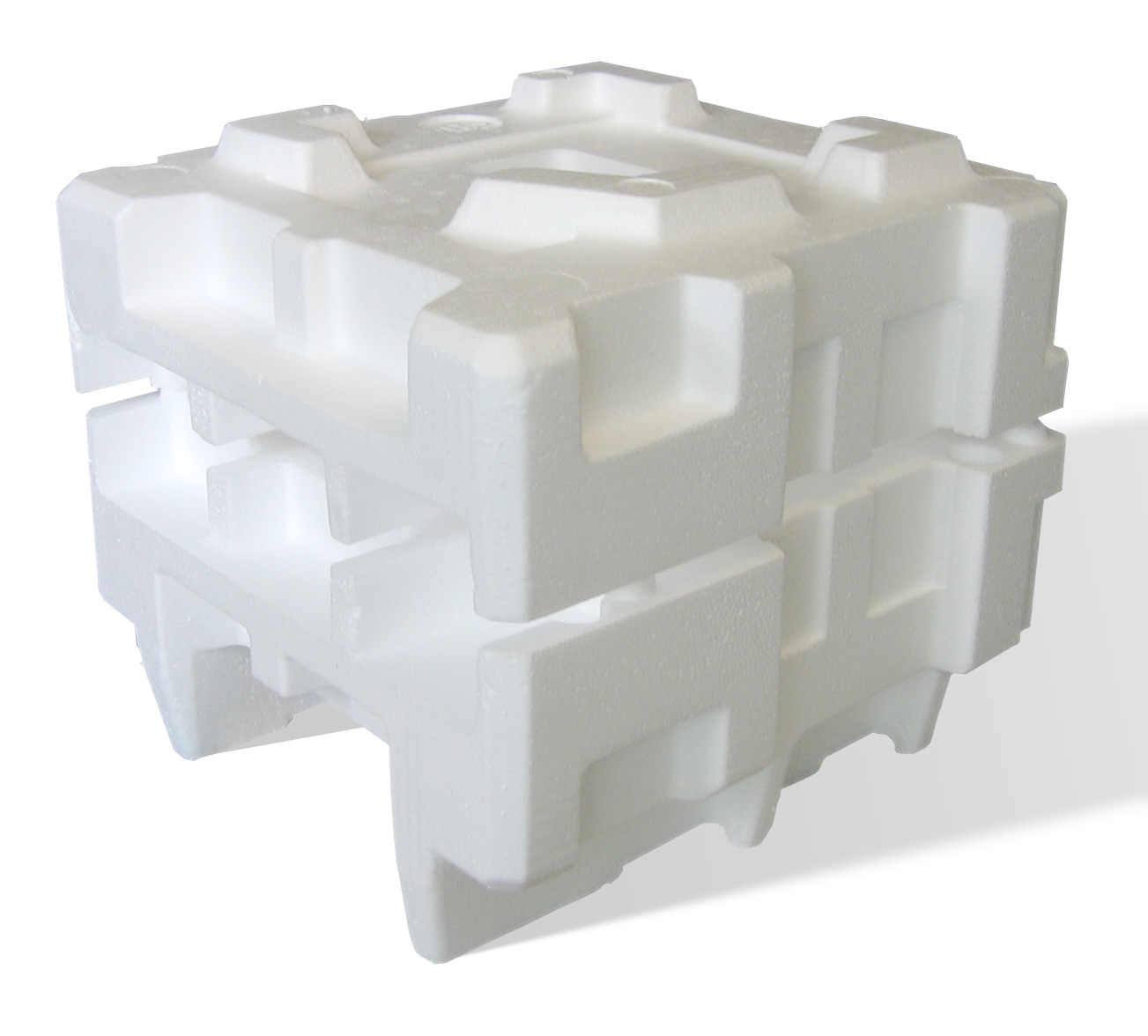

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a poor barrier to oxygen and water vapour and has a relatively low melting point. Polystyrene is one of the most widely used plastics, the scale of its production being several million tonnes per year. Polystyrene can be naturally transparent, but can be colored with colorants. Uses include protective packaging (such as packing peanuts and in the jewel cases used for storage of optical discs such as CDs and occasionally DVDs), containers, lids, bottles, trays, tumblers, disposable cutlery, in the making of models, and as an alternative material for phonograph records. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastics Market Share En

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to its widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives. 9.2 billion tonnes of plastic are estimated to have been made between 1950 and 2017. More than half this plastic has been produced since 2004. In 2020, 400 million tonnes of plastic were produced. If global trends on plastic demand continue, it is estimated that by 2050 annual global plastic production will reach over 1,10 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microplastics

Microplastics are fragments of any type of plastic less than in length, according to the U.S. National Oceanic and Atmospheric Administration (NOAA) and the European Chemicals Agency. They cause pollution by entering natural ecosystems from a variety of sources, including cosmetics, clothing, food packaging, and industrial processes. The term ''macroplastics'' is used to differentiate microplastics from larger plastic waste, such as plastic bottles. Two classifications of microplastics are currently recognized. Primary microplastics include any plastic fragments or particles that are already 5.0 mm in size or less before entering the environment. These include microfibers from clothing, microbeads, and plastic pellets (also known as nurdles). Secondary microplastics arise from the degradation (breakdown) of larger plastic products through natural weathering processes after entering the environment. Such sources of secondary microplastics include water and soda bottles, fis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene Terephthalate

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins. In 2016, annual production of PET was 56 million tons. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym ''PET'' is generally used in relation to packaging. Polyester makes up about 18% of world polymer production and is the fourth-most-produced polymer after polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). PET consists of repeating (C10H8O4) units. PET is commonly recycled, and has the digit 1 (♳) as its resin identification code (RIC). T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyolefins

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More specialized polyolefins include polyisobutylene and polymethylpentene. They are all colorless or white oils or solids. Many copolymers are known, such as polybutene, which derives from a mixture of different butene isomers. The name of each polyolefin indicates the olefin from which it is prepared; for example, polyethylene is derived from ethylene, and polymethylpentene is derived from 4-methyl-1-pentene. Polyolefins are not olefins themselves because the double bond of each olefin monomer is opened in order to form the polymer. Monomers having more than one double bond such as butadiene and isoprene yield polymers that contain double bonds ( polybutadiene and polyisoprene) and are usually not considered polyolefins. Polyolefins are the foundati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Commodity Plastics

Commodity plastics or commodity polymers are plastics produced in high volumes for applications where exceptional material properties are not needed (such as packaging, food containers, and household products). In contrast to engineering plastics, commodity plastics tend to be inexpensive to produce and exhibit relatively weak mechanical properties. Some examples of commodity plastics are polyethylene, polypropylene, polystyrene, polyvinyl chloride, and poly(methyl methacrylate). Globally, the most widely used thermoplastic includes both Polypropylene and Polyethylene. Products made from commodity plastics include disposable plates, disposable cups, photographic and magnetic tape, clothing, reusable bags, medical trays, and seeding trays. Several investigations suggest that the kinetics of thermal degradation of commodity plastics is important to realize the complications it may bring because of the temperature that it goes through which includes production process or manufacturi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |