|

Out Of Autoclave

Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material. Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. OOA curing achieves the desired fiber content and elimination of voids by placing the layup within a closed mold and applying vacuum, pressure, and heat by means other than an autoclave. An RTM press is the typical method of applying heat and pressure to the closed mold. There are several out of autoclave technologies in current use including resin transfer molding (RTM), Same Qualified Resin Transfer Molding (SQRTM), vacuum-assisted resin transfer molding (VARTM), and balanced pressure fluid molding. The most advanced of these processes can produce high-tech net shape aircraft components. Processes Resin transfer molding Resin transfer molding (RTM) is a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

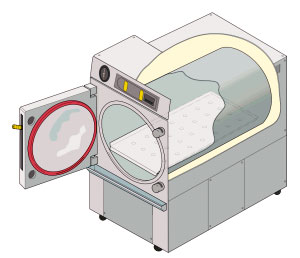

Autoclave (industrial)

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in the manufacturing of composites. Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at for around 30-60 minutes at a pressure of 15 psi (103 kPa or 1.02 atm) depending on the size of the load and the contents. The autoclave was invented by Charles Chamberland in 1879, although a precursor known as the steam digester was created by Denis Papin in 1679. The name comes from Greek ''auto-'', ultimately meaning self, and Latin ''clavis'' meaning key, thus a self-locking device. Uses Sterilization autoclav ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerospace Manufacturer

An aerospace manufacturer is a company or individual involved in the various aspects of designing, building, testing, selling, and maintaining aircraft, aircraft parts, missiles, rockets, or spacecraft. Aerospace is a high technology industry. The aircraft industry is the industry supporting aviation by building aircraft and manufacturing aircraft parts for their maintenance. This includes aircraft and parts used for civil aviation and military aviation. Most production is done pursuant to type certificates and Defense Standards issued by a government body. This term has been largely subsumed by the more encompassing term: "aerospace industry". Market In 2015 the aircraft production was worth US$180.3 Billion: 61% airliners, 14% business and general aviation, 12% Military aircraft, 10% military rotary wing and 3% civil rotary wing; while their MRO was worth $135.1 Bn or $ Bn combined. The global aerospace industry was worth $838 billion in 2017: Aircraft & Engine OEMs rep ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites ( composite ceramic and metal matrices) *Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Assisted Resin Transfer Molding

Vacuum Assisted Resin Transfer Molding (VARTM) or Vacuum Injected Molding (VIM) is a closed mold, out of autoclave (OOA) Autoclave Quality Outside The Autoclave? nline Available: http://www.compositesworld.com/articles/autoclave-quality-outside-the-autoclave. composite manufacturing process. VARTM is a variation of Resin Transfer Molding (RTM) with its distinguishing characteristic being the replacement of the top portion of a mold tool with a vacuum bag and the use of a vacuum to assist in resin flow. The process involves the use of a vacuum to facilitate resin flow into a fiber layup contained within a mold tool covered by a vacuum bag. After the impregnation occurs the composite part is allowed to cure at room temperature with an optional post cure sometimes carried out. Process Typically, this process uses a low viscosity (100 to 1000 cP) polyester or vinyl ester left, 144px, Vinyl acetate is a commercially important monomer that is classified as a vinyl ester (i.e. an e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pre-preg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling; this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure. The main idea behind a pre-preg material is the use of anisotropic mechanical properties along the fibers, while the polymer matrix provides filling properties, keeping the fibers in a single system. Pre-preg allows one to impregnate the fibers on a flat workable surface, or rather in an industrial process, and then later ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mitsubishi Regional Jet

The Mitsubishi SpaceJet (, originally named ''Mitsubishi Regional Jet'') is a regional jet developed by Japanese company Mitsubishi Aircraft Corporation (MAC), a Mitsubishi Heavy Industries (MHI) subsidiary. The airframe is made mainly in aluminium with a carbon fibre composites empennage. The low-wing twinjet is powered by underwing Pratt & Whitney PW1000Gs, and was the first program to select the geared turbofan. The M90 (originally named MRJ90) should seat 86 to 96, while the smaller MRJ70 was to accommodate 70 to 80 passengers. The MRJ70 was replaced by the SpaceJet M100, stretched by 1.1 m (3 ft 7 in) to better meet US scope clauses at 76 seats with premium seating. It is comparable with the Embraer E-Jet E2. MHI first announced the concept in June 2007, then targeting certification for 2012, as the first Japanese airliner since the 1962 NAMC YS-11. After a delayed development, the maiden flight of the MRJ90 took place on 11 November 2015. In June 2019, Mitsubishi rebranded ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aviation Week & Space Technology

''Aviation Week & Space Technology'', often abbreviated ''Aviation Week'' or ''AW&ST'', is the flagship magazine of the Aviation Week Network. The weekly magazine is available in print and online, reporting on the aerospace, defense and aviation industries, with a core focus on aerospace technology. It has a reputation for its contacts inside the United States military and industry organizations. ''Aviation Week'' was a favorite conduit for defense-related companies and labs to leak information to the public as part of their policy by press release efforts. This led to it being informally referred to "Aviation Leak and Space Mythology". History The magazine was first published in August 1916. Early editors Ladislas d'Orsy and Donald W. McIlhiney (1921 to 25) were Quiet Birdmen. Publisher (1927 to 29) Earl D. Osborn was also a Quiet Birdman. With the coming of the Space Age, the current title was adopted in 1960. Other titles the magazine has held include ''Aviation & Aircraft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

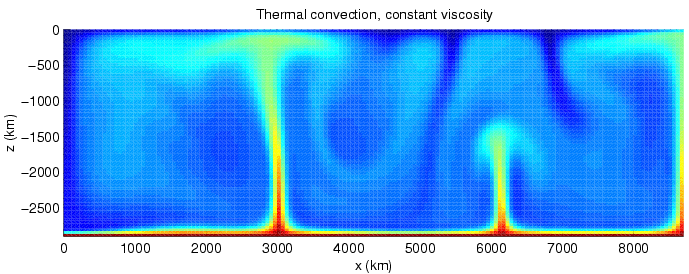

Heat Transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, Convection (heat transfer), thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species (mass transfer in the form of advection), either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system. Heat conduction, also called diffusion, is the direct microscopic exchanges of kinetic energy of particles (such as molecules) or quasiparticles (such as lattice waves) through the boundary between two systems. When an object is at a different temperature from another body or its surroundings, heat flows so that the body and the surroundings reach the same temperature, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosetting Polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent (''catalyst'', ''hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product form b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prepreg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling; this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure. The main idea behind a pre-preg material is the use of anisotropic mechanical properties along the fibers, while the polymer matrix provides filling properties, keeping the fibers in a single system. Pre-preg allows one to impregnate the fibers on a flat workable surface, or rather in an industrial process, and then later ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Autoclave

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in the manufacturing of composites. Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at for around 30-60 minutes at a pressure of 15 psi (103 kPa or 1.02 atm) depending on the size of the load and the contents. The autoclave was invented by Charles Chamberland in 1879, although a precursor known as the steam digester was created by Denis Papin in 1679. The name comes from Greek ''auto-'', ultimately meaning self, and Latin ''clavis'' meaning key, thus a self-locking device. Uses Sterilization autoclav ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Energy Consumption

Energy consumption is the amount of energy used. Biology In the body, energy consumption is part of energy homeostasis. It derived from food energy. Energy consumption in the body is a product of the basal metabolic rate and the physical activity level. The physical activity level are defined for a non-pregnancy, pregnant, non-lactation, lactating adult as that person's total energy expenditure (TEE) in a 24-hour period, divided by his or her basal metabolic rate (BMR): :\text=\frac Demographics Topics related to energy consumption in a demographic sense are: * World energy supply and consumption * Domestic energy consumption * Electric energy consumption Effects of energy consumption * Environmental impact of the energy industry ** Global warming * White's law Reduction of energy consumption * Energy conservation, the practice of decreasing the quantity of energy used * Efficient energy use See also * Efficient energy use, Energy efficiency * Energy efficiency in transpor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)