|

Nanoindentation

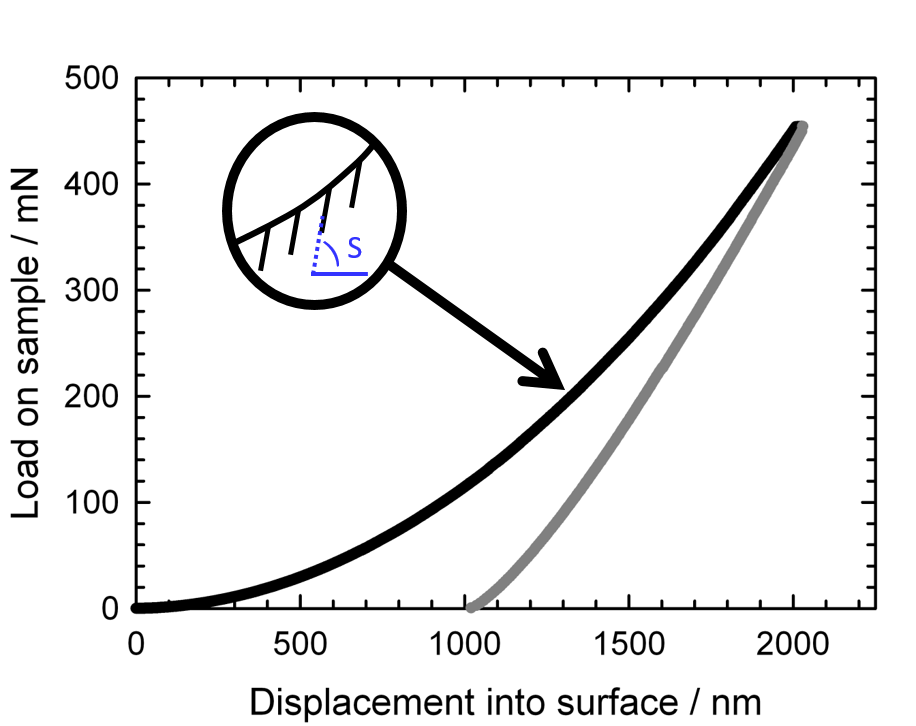

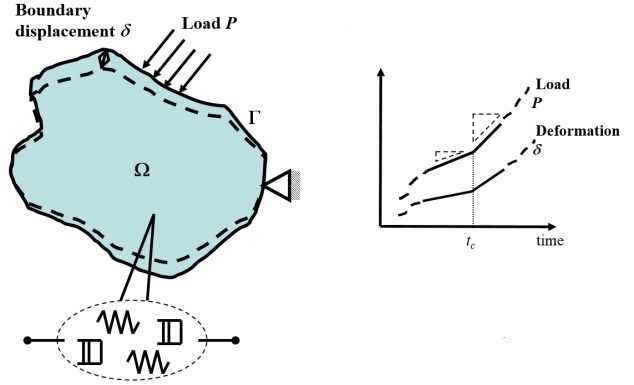

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material. Background In a traditional indentation test (macro or micro indentation), a hard tip whose mechanical properties are known (frequently made of a very hard material like diamond) is pressed into a sample whose properties are unknown. The load placed on the indenter tip is increased as the tip penetrates further into the specimen and soon reaches a user-defined value. At this point, the load may be held constant for a period or removed. The area of the residual indentation in the sample is measured and the hardness, H, is defined as the maximum load, P_, divided by the residual indentation area, A_r: :H=\frac . For most techniques, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoindentation CSM Schematics

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material. Background In a traditional indentation test (macro or micro indentation), a hard tip whose mechanical properties are known (frequently made of a very hard material like diamond) is pressed into a sample whose properties are unknown. The load placed on the indenter tip is increased as the tip penetrates further into the specimen and soon reaches a user-defined value. At this point, the load may be held constant for a period or removed. The area of the residual indentation in the sample is measured and the hardness, H, is defined as the maximum load, P_, divided by the residual indentation area, A_r: :H=\frac . For most techniques, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoindenter

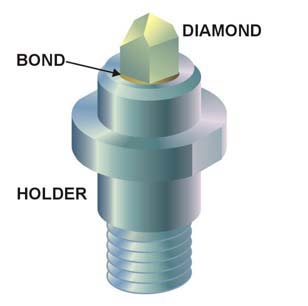

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called ''depth sensing indentation'' or ''instrumented indentation'', gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties. Types There are many types of nanoindenters in current use differing mainly on their tip geometry. Among the numerous available geometries are three and four sided pyramids, wedges, cones, cylinders, filaments, and spheres. Several geometries have become a well established common standard due to their extended use and well known properties; such as Berkovich, cube corner, V ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nano Indenter

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called ''depth sensing indentation'' or ''instrumented indentation'', gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties. Types There are many types of nanoindenters in current use differing mainly on their tip geometry. Among the numerous available geometries are three and four sided pyramids, wedges, cones, cylinders, filaments, and spheres. Several geometries have become a well established common standard due to their extended use and well known properties; such as Berkovich, cube corner, V ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Young's Modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied lengthwise. It quantifies the relationship between tensile/compressive stress \sigma (force per unit area) and axial strain \varepsilon (proportional deformation) in the linear elastic region of a material and is determined using the formula: E = \frac Young's moduli are typically so large that they are expressed not in pascals but in gigapascals (GPa). Example: * Silly Putty (increasing pressure: length increases quickly, meaning tiny E) * Aluminum (increasing pressure: length increases slowly, meaning high E) Higher Young's modulus corresponds to greater (lengthwise) stiffness. Although Young's modulus is named after the 19th-century British scientist Thomas Young, the concept was developed in 1727 by Leonhard Euler. The first ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Berkovich Tip

A Berkovich tip is a type of nanoindenter tip used for testing the indentation hardness of a material. It is a three-sided pyramid which is geometrically self-similar. The popular Berkovich now has a very flat profile, with a total included angle of 142.3 degrees and a half angle of 65.27 degrees, measured from the axis to one of the pyramid flats. This Berkovich tip has the same projected area-to-depth ratio as a Vickers indenter. The original tip shape was invented by Russian scientist E.S. Berkovich in the USSR c. 1950, which has a half angle of 65.03 degrees.M.M. Khrushchov & E.S. Berkovich, "Methods of Determining the Hardness of Very Hard Materials: The Hardness of Diamond," ''Zavodskaya Laboratoria'', 1950 (2), p 193 -196 (in Russian). Translated into English by W.G.C and published in ''Industrial Diamond Review'', Vol. 11, Feb 1951, p 42-49 (in English). As it is three sided, it is easier to grind these tips to a sharp point and so is more readily employed for nanoindenta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Indentation Hardness

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale. When testing metals, indentation hardness correlates roughly linearly with tensile strength, but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers. Material hardness Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoscopic Scale

The nanoscopic scale (or nanoscale) usually refers to structures with a length scale applicable to nanotechnology, usually cited as 1–100 nanometers (nm). A nanometer is a billionth of a meter. The nanoscopic scale is (roughly speaking) a lower bound to the mesoscopic scale for most solids. For technical purposes, the nanoscopic scale is the size at which fluctuations in the averaged properties (due to the motion and behavior of individual particles) begin to have a significant effect (often a few percent) on the behavior of a system, and must be taken into account in its analysis. The nanoscopic scale is sometimes marked as the point where the properties of a material change; above this point, the properties of a material are caused by 'bulk' or 'volume' effects, namely which atoms are present, how they are bonded, and in what ratios. Below this point, the properties of a material change, and while the type of atoms present and their relative orientations are still importa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond

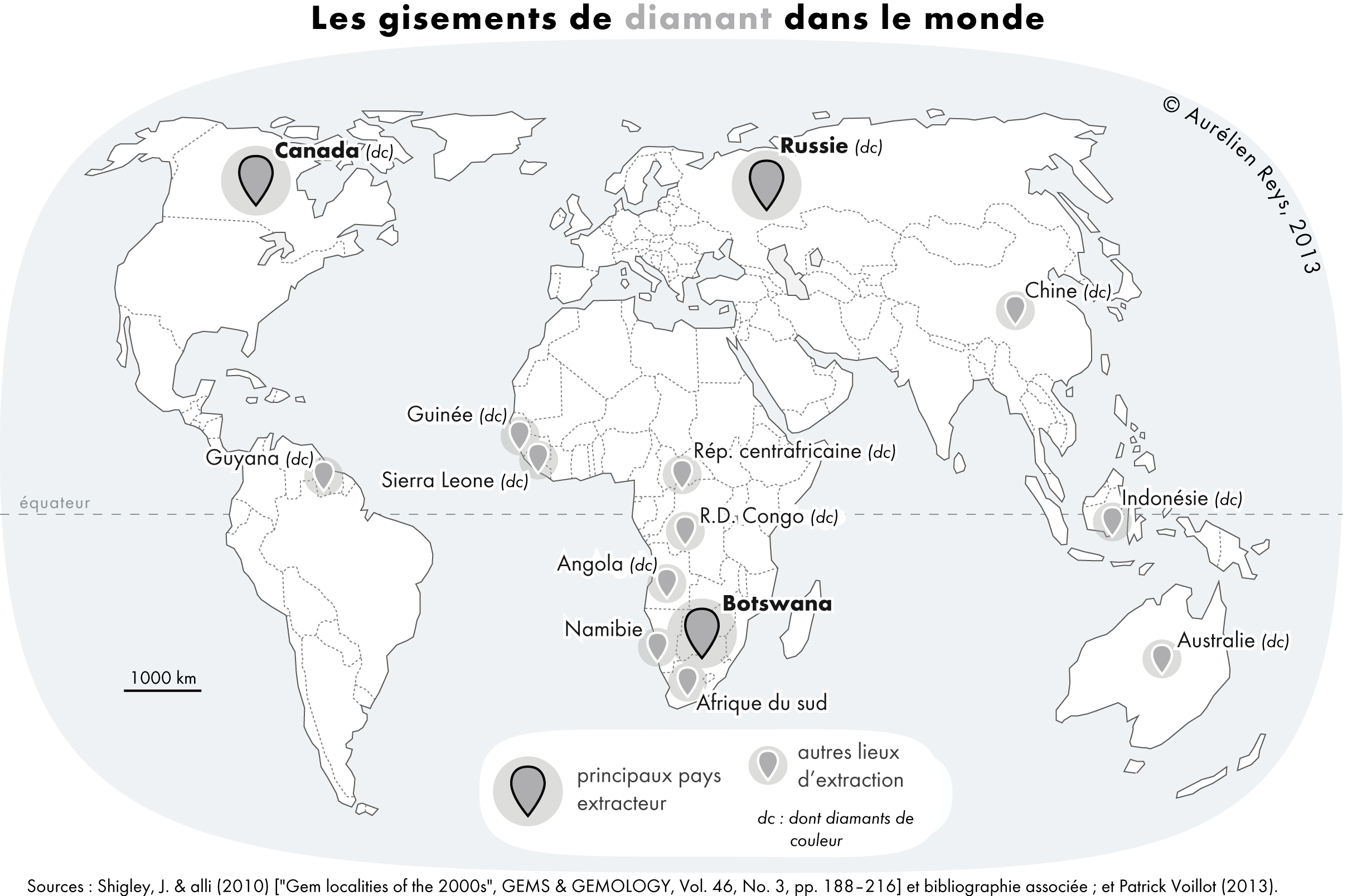

Diamond is a solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Another solid form of carbon known as graphite is the chemically stable form of carbon at room temperature and pressure, but diamond is metastable and converts to it at a negligible rate under those conditions. Diamond has the highest hardness and thermal conductivity of any natural material, properties that are used in major industrial applications such as cutting and polishing tools. They are also the reason that diamond anvil cells can subject materials to pressures found deep in the Earth. Because the arrangement of atoms in diamond is extremely rigid, few types of impurity can contaminate it (two exceptions are boron and nitrogen). Small numbers of defects or impurities (about one per million of lattice atoms) color diamond blue (boron), yellow (nitrogen), brown (defects), green (radiation exposure), purple, pink, orange, or red. Diamond also has a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanometer

330px, Different lengths as in respect to the molecular scale. The nanometre (international spelling as used by the International Bureau of Weights and Measures; SI symbol: nm) or nanometer (American and British English spelling differences#-re, -er, American spelling) is a units of measurement, unit of length in the International System of Units (SI), equal to one billionth ( short scale) of a metre () and to 1000 picometres. One nanometre can be expressed in scientific notation as , and as metres. History The nanometre was formerly known as the millimicrometre – or, more commonly, the millimicron for short – since it is of a micron (micrometre), and was often denoted by the symbol mμ or (more rarely and confusingly, since it logically should refer to a ''millionth'' of a micron) as μμ. Etymology The name combines the SI prefix '' nano-'' (from the Ancient Greek , ', "dwarf") with the parent unit name ''metre'' (from Greek , ', "unit of measuremen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Newton (unit)

The newton (symbol: N) is the unit of force in the International System of Units (SI). It is defined as 1 kg⋅m/s, the force which gives a mass of 1 kilogram an acceleration of 1 metre per second per second. It is named after Isaac Newton in recognition of his work on classical mechanics, specifically Newton's second law of motion. Definition A newton is defined as 1 kg⋅m/s (it is a derived unit which is defined in terms of the SI base units). One newton is therefore the force needed to accelerate one kilogram of mass at the rate of one metre per second squared in the direction of the applied force. The units "metre per second squared" can be understood as measuring a rate of change in velocity per unit of time, i.e. an increase in velocity by 1 metre per second every second. In 1946, Conférence Générale des Poids et Mesures (CGPM) Resolution 2 standardized the unit of force in the MKS system of units to be the amount needed to accelerate 1 kilogram of mass at the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boltzmann's Constant

The Boltzmann constant ( or ) is the proportionality factor that relates the average relative kinetic energy of particles in a gas with the thermodynamic temperature of the gas. It occurs in the definitions of the kelvin and the gas constant, and in Planck's law of black-body radiation and Boltzmann's entropy formula, and is used in calculating thermal noise in resistors. The Boltzmann constant has dimensions of energy divided by temperature, the same as entropy. It is named after the Austrian scientist Ludwig Boltzmann. As part of the 2019 redefinition of SI base units, the Boltzmann constant is one of the seven " defining constants" that have been given exact definitions. They are used in various combinations to define the seven SI base units. The Boltzmann constant is defined to be exactly . Roles of the Boltzmann constant Macroscopically, the ideal gas law states that, for an ideal gas, the product of pressure and volume is proportional to the product of amount of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Activation Volume

Activation, in chemistry and biology, is the process whereby something is prepared or excited for a subsequent reaction. Chemistry In chemistry, "activation" refers to the reversible transition of a molecule into a nearly identical chemical or physical state, with the defining characteristic being that this resultant state exhibits an increased propensity to undergo a specified chemical reaction. Thus, activation is conceptually the opposite of protection, in which the resulting state exhibits a ''decreased'' propensity to undergo a certain reaction. The energy of activation specifies the amount of free energy the reactants must possess (in addition to their rest energy) in order to initiate their conversion into corresponding products—that is, in order to reach the transition state for the reaction. The energy needed for activation can be quite small, and often it is provided by the natural random thermal fluctuations of the molecules themselves (i.e. without any exter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |