|

Necking (engineering)

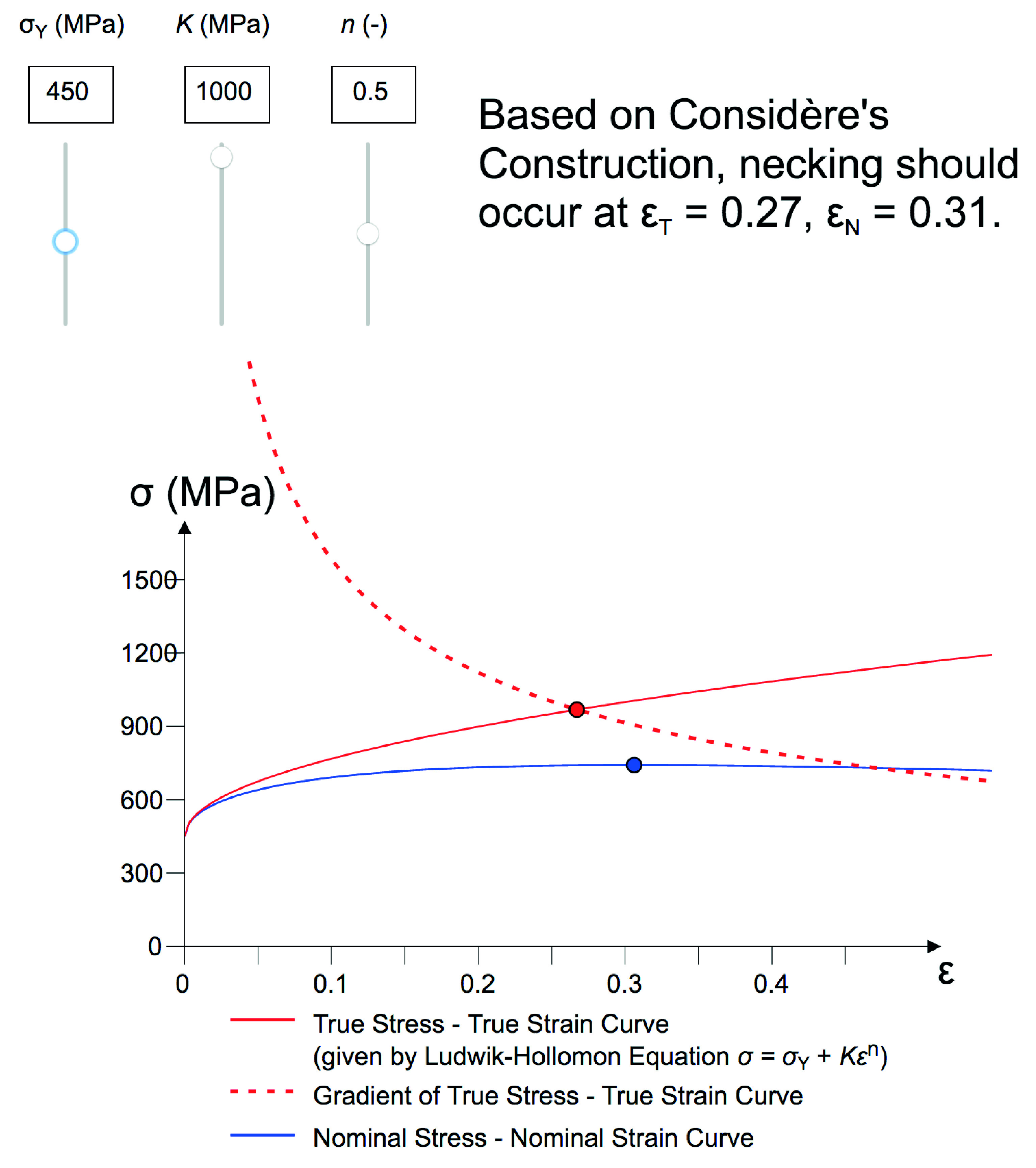

Necking, in engineering or materials science, is a mode of tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck". Because the local strains in the neck are large, necking is often closely associated with yielding, a form of plastic deformation associated with ductile materials, often metals or polymers. Once necking has begun, the neck becomes the exclusive location of yielding in the material, as the reduced area gives the neck the largest local stress. Formation Necking results from an instability during tensile deformation when the cross-sectional area of the sample decreases by a greater proportion than the material strain hardens.Armand Considèrepublished the basic criterion for necking in 1885, in the context of the stability of large scale structures such as bridges. Three concepts provide the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering

Engineering is the use of scientific method, scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad range of more specialized List of engineering branches, fields of engineering, each with a more specific emphasis on particular areas of applied mathematics, applied science, and types of application. See glossary of engineering. The term ''engineering'' is derived from the Latin ''ingenium'', meaning "cleverness" and ''ingeniare'', meaning "to contrive, devise". Definition The American Engineers' Council for Professional Development (ECPD, the predecessor of Accreditation Board for Engineering and Technology, ABET) has defined "engineering" as: The creative application of scientific principles to design or develop structures, machines, apparatus, or manufacturing processes, or works utilizing them singly or in combination; or to construct o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Trace Necking

In printed circuit boards, teardrops are typically drop-shaped features at the junction of vias (''teardrop vias'') or contact pads (''teardrop pads'') and traces (''teardrop traces''). The main purpose of teardrops is to enhance structural integrity in presence of thermal or mechanical stresses, for example due to vibration or flexing. Structural integrity may be compromised, e.g., by misalignment during drilling, so that too much copper may be removed by the drill hole in the area where a trace connects to the pad or via. An extra advantage is the enlarging of manufacturing tolerances, making manufacturing easier and cheaper. While a typical shape of a teardrop is straight-line tapering, they may be concave. This type of teardrop is also called ''filleting'' or ''straight''. To produce a ''snowman''-shaped teardrop, a secondary pad of smaller size is added at the junction overlapping with the primary pad (hence the nickname). Necking For similar reasons, a technique ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress–strain Curve

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress (mechanics), stress and Deformation (physics)#Strain, strain. It is obtained by gradually applying Structural load, load to a test coupon and measuring the Deformation (engineering), deformation, from which the stress and strain can be determined (see tensile testing). These curves reveal many of the List of materials properties, properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength. Definition Generally speaking, curves representing the relationship between stress and strain in any form of deformation can be regarded as stress–strain curves. The stress and strain can be normal, shear, or mixture, also can be uniaxial, biaxial, or multiaxial, even change with time. The form of deformation can be compression, stretching, torsion, rotation, and so on. If not mentioned otherwise, stress–strain curve refers to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they wer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultimate Tensile Stress

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DoITPoMS

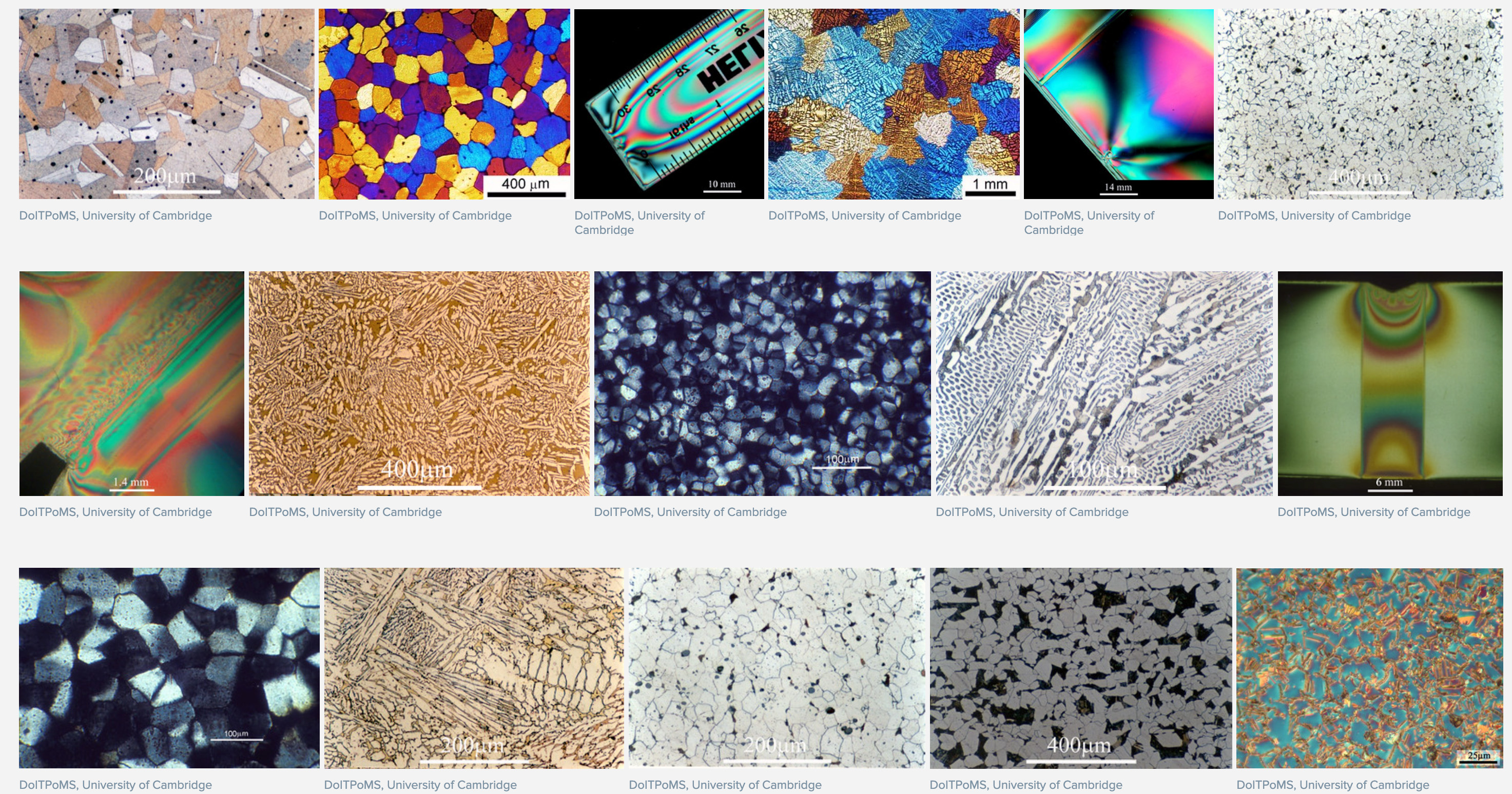

Dissemination of IT for the Promotion of Materials Science (DoITPoMS) is a web-based educational software resource designed to facilitate the teaching and learning of Materials science, at the tertiary level for free. History The DoITPoMS project originated in the early 1990s, incorporating customized online sources into the curriculum of the Materials Science courses in the Natural Sciences Tripos of the University Cambridge. The initiative became formalized in 2000, with the start of a project supported by the UK national Fund for the Development of Teaching and Learning (FDTL). This was led by the Department of Materials Science and Metallurgy in Cambridge, with five partner institutions, including the University of Leeds, London Metropolitan University, the University of Manchester, Oxford Brookes University and the University of Sheffield. This period of cooperation lasted for about 10 years. The FDTL project was aimed at building on expertise concerning the use of Infor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polymer Chains

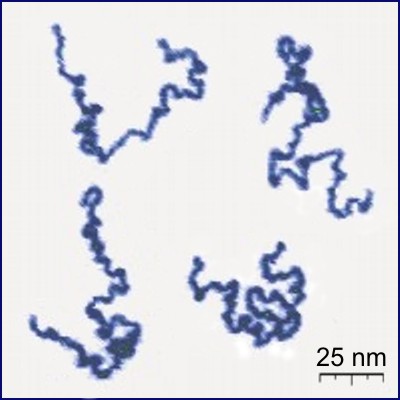

A polymer (; Greek ''poly-'', "many" + ''-mer'', "part") is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. The term "polymer" derives from the Greek word πολύς (''polus'', meaning "many, much") and μέρος (''meros'', meaning "part ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |