|

Micro Drive

Micro drive is a type of bicycle drivetrain, mostly BMX and MTB, that uses smaller than standard-sized sprockets. The smallest rear sprocket that fits on a freehub body is an 10-tooth, but with the use of a cassette hub, sometimes called a micro drive rear hub, sprockets as small as 8 teeth may be used. The advantage of micro drive is that it means a smaller front sprocket, or chainring, can be used without affecting the gear ratio, providing better ground clearance. For example, a bike using a 32-tooth chainring with a 16-tooth rear sprocket can switch to using an 18-tooth chainring and a 9-tooth sprocket, and still have a 2:1 ratio. Another advantage is the reduction in weight with the reduction in size of all the parts. The disadvantage is increased stresses on the drive train, leading to increased wear and even premature failure. As the front and rear sprockets become smaller, the tension in the Chain increases, and stretching and breaking can occur more easily. Designers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Drivetrain Systems

Bicycle drivetrain systems are used to transmit power on bicycles, tricycles, quadracycles, unicycles, or other human-powered vehicles from the riders to the drive wheels. Most also include some type of a mechanism to convert speed and torque via gear ratios. History The history of bicycle drivetrain systems is closely linked to the history of the bicycle. Major changes in bicycle form have often been initiated or accompanied by advances in drivetrain systems. Several early drivetrains used straight-cut gears that meshed directly with each other outside of the hub. Some bicycles have used a double-sided rear wheel, with different-sized sprockets on each side. To change gears, the rider would stop and dismount, remove the rear wheel and reinstall it in the reverse direction. Derailleur systems were first developed in the late 19th century, but the modern cable-operated parallelogram derailleur was invented in the 1950s. * Draisine * Penny-farthing * Safety bicycle Power coll ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mountain Bike

A mountain bike (MTB) or mountain bicycle is a bicycle designed for off-road cycling. Mountain bikes share some similarities with other bicycles, but incorporate features designed to enhance durability and performance in rough terrain, which makes them heavier, more complex and less efficient on smooth surfaces. These typically include a suspension fork, large knobby tires, more durable wheels, more powerful brakes, straight, extra wide handlebars to improve balance and comfort over rough terrain, and wide-ratio gearing optimised for topography and application (e.g., steep climbing or fast descending). Rear suspension is ubiquitous in heavier-duty bikes and now common even in lighter bikes. Dropper posts can be installed to allow the rider to quickly adjust the seat height (an elevated seat position is more effective for pedaling, but poses a hazard in aggressive maneuvers). Mountain bikes are generally specialized for use on mountain trails, single track, fire roads, and othe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sprocket

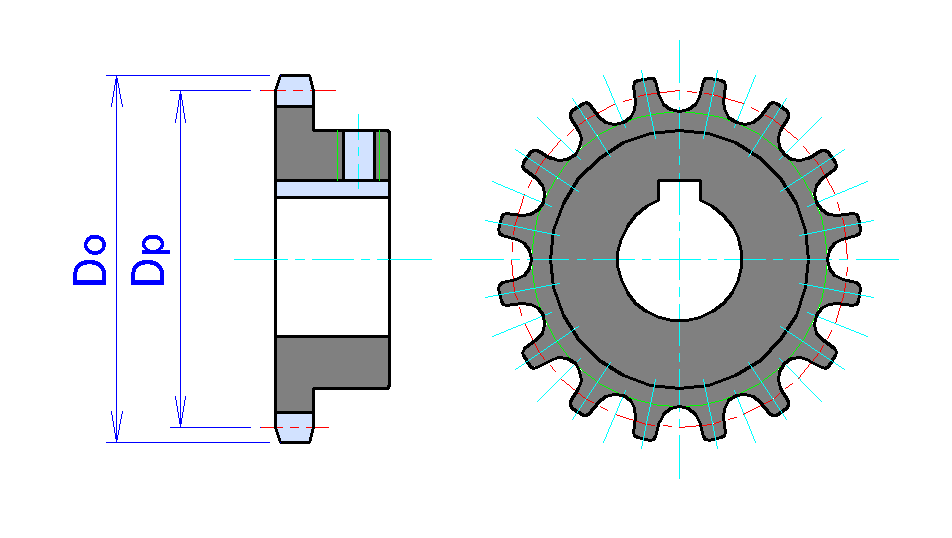

A sprocket, sprocket-wheel or chainwheel is a profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth except for timing pulleys used with toothed belts. Sprockets are used in bicycles, motorcycles, tracked vehicles, and other machinery either to transmit rotary motion between two shafts where gears are unsuitable or to impart linear motion to a track, tape etc. Perhaps the most common form of sprocket may be found in the bicycle, in which the pedal shaft carries a large sprocket-wheel, which drives a chain, which, in turn, drives a small sprocket on the axle of the rear wheel. Early automobiles were also largely driven by sprocket and chain mechanism, a practice la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Freehub

A freehub is a type of bicycle hub that incorporates a ratcheting mechanism. A set of sprockets (called a "cassette") is mounted onto a splined shaft of the freehub to engage the chain. The ratcheting mechanism is a part of the hub, in contrast to a freewheel, an older technology, which contains both the sprockets and a ratcheting mechanism in a single unit separate from the hub. In many high-end and midrange bicycles, freehubs have replaced freewheel systems. A freewheel mechanism allows a rider to stop pedalling whilst the cycle is still in forward motion. On a cycle without a freewheel mechanism, the rider has to keep pedalling whenever the cycle is moving. Comparison to freewheels The freehub concept answers several drawbacks encountered with the freewheel design: * Freewheels are threaded onto an axle hub, using conventional right-hand threads. As the bicycle rider pedals, the freewheel is continuously kept tight, as chain torque is in the right-hand direction. This be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hub Gear

A hub gear, internal-gear hub, internally geared hub or just gear hub is a gear ratio changing system commonly used on bicycles that is implemented with planetary or epicyclic gears. The gears and lubricants are sealed within the shell of the hub gear, in contrast with derailleur gears where the gears and mechanism are exposed to the elements. Changing the gear ratio was traditionally accomplished by a shift lever connected to the hub with a Bowden cable, and twist-grip style shifters have become common. Hub gear systems generally have a long and largely maintenance-free life though some are not suitable for high-stress use in competitions or hilly, off-road conditions. Many commuter or urban cycles such as European city bikes are now commonly fitted with 7-speed gear-hubs and 8-speed systems are becoming increasingly available. Older or less costly utility bicycles often use 3-speed gear-hubs, such as in bicycle sharing systems. Many folding bicycles use 3-speed gear-hubs. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chainring

The crankset (in the US) or chainset (in the UK), is the component of a bicycle drivetrain that converts the reciprocating motion of the rider's legs into rotational motion used to drive the chain or belt, which in turn drives the rear wheel. It consists of one or more sprockets, also called ''chainrings'' or ''chainwheels'' attached to the '' cranks'', ''arms'', or ''crankarms'' to which the pedals attach. It is connected to the rider by the pedals, to the bicycle frame by the bottom bracket, and to the rear sprocket, cassette or freewheel via the chain. Parts Cranks The two ''cranks'', one on each side and usually mounted 180° apart, connect the bottom bracket axle to the pedals. Lengths Bicycle cranks can vary in length to accommodate different sized riders and different types of cycling. Crank length is measured from the center of the pedal spindle to the center of the bottom bracket spindle or axle. The larger bicycle component manufacturers typically offer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Ratio

A gear train is a mechanical system formed by mounting gears on a frame so the teeth of the gears engage. Gear teeth are designed to ensure the pitch circles of engaging gears roll on each other without slipping, providing a smooth transmission of rotation from one gear to the next. Features of gears and gear trains include: * The gear ratio of the pitch circles of mating gears defines the speed ratio and the mechanical advantage of the gear set. * A planetary gear train provides high gear reduction in a compact package. * It is possible to design gear teeth for gears that are non-circular, yet still transmit torque smoothly. * The speed ratios of chain and belt drives are computed in the same way as gear ratios. See bicycle gearing. The transmission of rotation between contacting toothed wheels can be traced back to the Antikythera mechanism of Greece and the south-pointing chariot of China. Illustrations by the Renaissance scientist Georgius Agricola show gear trains with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Chain

A bicycle chain is a roller chain that transfers power from the pedals to the drive-wheel of a bicycle, thus propelling it. Most bicycle chains are made from plain carbon or alloy steel, but some are nickel-plated to prevent rust, or simply for aesthetics. History Obsolete chain designs previously used on bicycles included the block chain, the skip-link chain, and the Simpson lever chain. The first chains were of a simple, bushing-less design. These had inherent reliability problems and a bit more friction (and mechanical efficiency losses) than modern chains. With these limitations in mind, the Nevoigt brothers, of the German Diamant Bicycle Company, designed the roller chain in 1898, which uses bushings. More recently, the "bushingless roller chain" design has superseded the bushed chain. This design incorporates the bearing surface of the bushing into the inner side plate, with each plate creating half of the bushing. This reduces the number of parts needed to assemble ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yield Strength

In materials science and engineering, the yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation. The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically. The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producing permanent deformation. In some materials, such as aluminium, there is a gradual onset of non-linear behavior, making the precise yield point difficult to determine. In such a case, the offset yiel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |