|

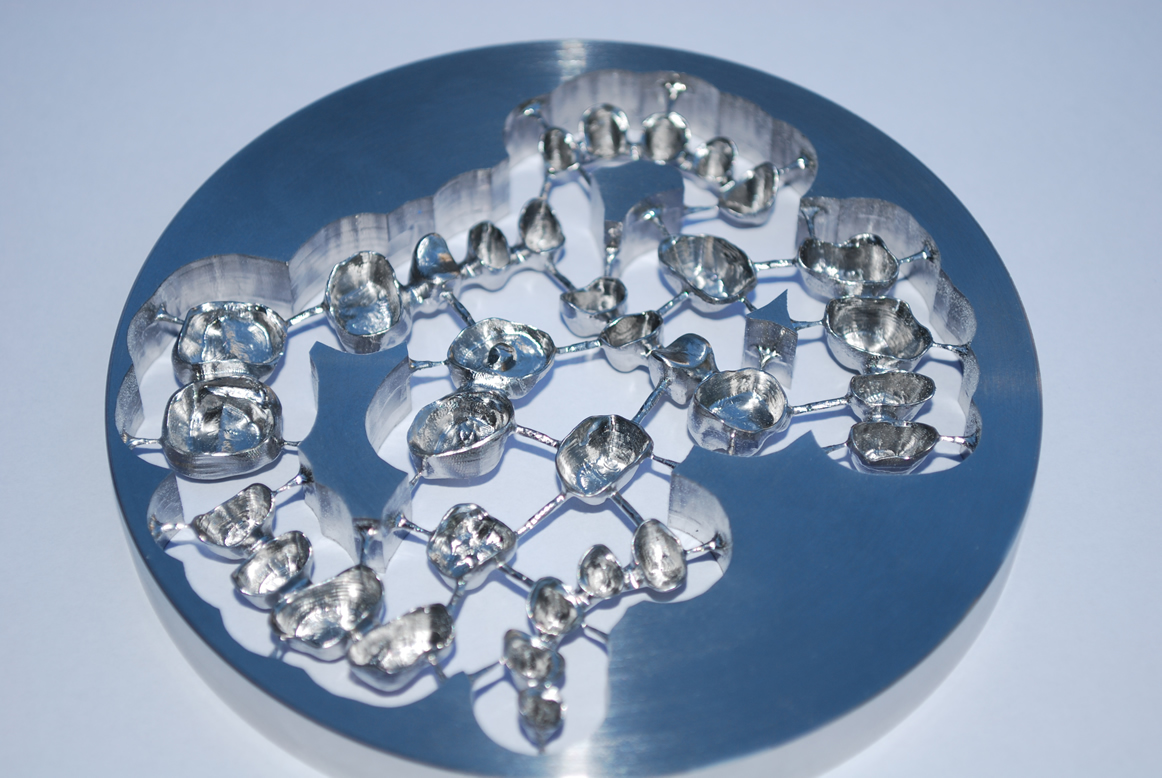

Metal Injection Molding

Metal injection molding (MIM) is a metalworking process in which finely-powdered metal is mixed with binder material to create a "feedstock" that is then shaped and solidified using injection molding. The molding process allows high volume, complex parts to be shaped in a single step. After molding, the part undergoes conditioning operations to remove the binder (debinding) and densify the powders. Finished products are small components used in many industries and applications. The behavior of MIM feedstock is governed by rheology, the study of sludges, suspensions, and other non-Newtonian fluids. Due to current equipment limitations, products must be molded using quantities of 100 grams or less per "shot" into the mold. This shot can be distributed into multiple cavities, making MIM cost-effective for small, intricate, high-volume products, which would otherwise be expensive to produce. MIM feedstock can be composed of a plethora of metals, but most common are stainles ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Passivation (chemistry)

Passivation, in physical chemistry and engineering, refers to coating a material so it becomes "passive", that is, less readily affected or corroded by the environment. Passivation involves creation of an outer layer of shield material that is applied as a microcoating, created by chemical reaction with the base material, or allowed to build by spontaneous oxidation in the air. As a technique, passivation is the use of a light coat of a protective material, such as metal oxide, to create a shield against corrosion. Passivation of silicon is used during fabrication of microelectronic devices. In electrochemical treatment of water, passivation reduces the effectiveness of the treatment by increasing the circuit resistance, and active measures are typically used to overcome this effect, the most common being polarity reversal, which results in limited rejection of the fouling layer. When exposed to air, many metals naturally form a hard, relatively inert surface layer, usually an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

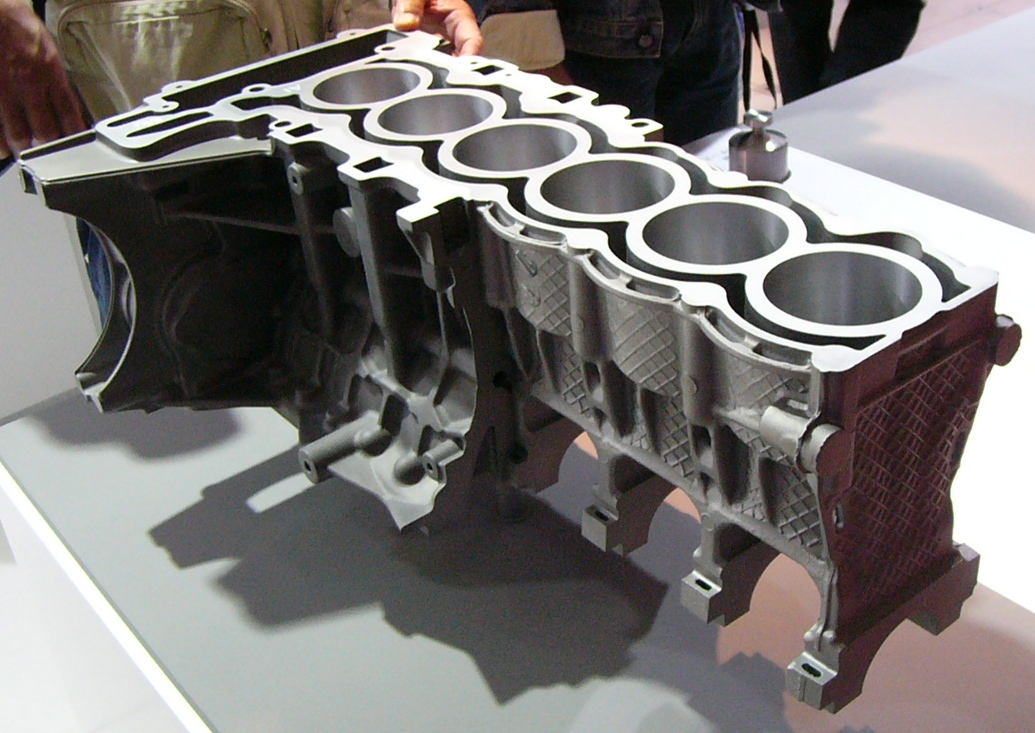

Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting process. Die castings are characterized by a very good surfac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Some 12,575 ASTM voluntary consensus standards operate globally. The organization's headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It is founded in 1902 as the American Section of the International Association for Testing Materials (see also International Organization for Standardization). History A group of scientists and engineers, led by Charles Dudley, formed ASTM in 1898 to address the frequent rail breaks affecting the fast-growing railroad industry. The group developed a standard for the steel used to fabricate rails. Originally called the "American Society for Testing Materials" in 1902, it became the "American Society for Testing And Materials" in 1961. In 2001, ASTM official ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electromagnetic Interference

Electromagnetic interference (EMI), also called radio-frequency interference (RFI) when in the radio frequency spectrum, is a disturbance generated by an external source that affects an electrical circuit by electromagnetic induction, electrostatic coupling, or conduction. The disturbance may degrade the performance of the circuit or even stop it from functioning. In the case of a data path, these effects can range from an increase in error rate to a total loss of the data. Both man-made and natural sources generate changing electrical currents and voltages that can cause EMI: ignition systems, cellular network of mobile phones, lightning, solar flares, and auroras (northern/southern lights). EMI frequently affects AM radios. It can also affect mobile phones, FM radios, and televisions, as well as observations for radio astronomy and atmospheric science. EMI can be used intentionally for radio jamming, as in electronic warfare. History Since the earliest days of ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tungsten Carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, cutting tools, chisels, abrasives, armor-piercing shells and jewelry. Tungsten carbide is approximately twice as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is double the density of steel—nearly midway between that of lead and gold. It is comparable with corundum (α-) in hardness and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond powder, wheels and compounds. Naming Historically referred to as Wolfram, ''Wolf Rahm'', wolframite ore was then later carburized and cemented with a binder creating a composite now called "tungsten carbide". Tungsten is Swedish for "heavy stone". Col ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cobalt-chrome

Cobalt-chrome or cobalt-chromium (CoCr) is a metal alloy of cobalt and chromium. Cobalt-chrome has a very high specific strength and is commonly used in gas turbines, dental implants, and orthopedic implants.ARCAM ASTM F75 CoCr Alloy History Co-Cr alloy was first discovered by in the early 1900s by fusing cobalt and chromium. The alloy was first discovered with many other elements such as and molybdenu ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and astronautics. Aerospace organizations research, design, manufacture, operate, or maintain both aircraft and spacecraft. The beginning of space and the ending of the air is considered as 100 km (62 mi) above the ground according to the physical explanation that the air pressure is too low for a lifting body to generate meaningful lift force without exceeding orbital velocity. Overview In most industrial countries, the aerospace industry is a cooperation of the public and private sectors. For example, several states have a civilian space program funded by the government, such as NASA, National Aeronautics and Space Administration in the United States, European Space Agency in Europe, the Canadian Space Agency in Canada, Indian Space Re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plating

Plating is a surface covering in which a metal is deposited on a conductive surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes. Jewelry typically uses plating to give a silver or gold finish. Thin-film deposition has plated objects as small as an atom, therefore plating finds uses in nanotechnology. There are several plating methods, and many variations. In one method, a solid surface is covered with a metal sheet, and then heat and pressure are applied to fuse them (a version of this is Sheffield plate). Other plating techniques include electroplating, vapor deposition under vacuum and sputter deposition. Recently, plating often refers to using liquids. Metallizing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |