|

Master Cylinder

In automotive engineering, the master cylinder is a control device that converts force (commonly from a driver's foot) into hydraulic pressure. This device controls slave cylinders located at the other end of the hydraulic brake system. As piston(s) move along the bore of the master cylinder, this movement is transferred through the hydraulic fluid, to result in a movement of the slave cylinder(s). The hydraulic pressure created by moving a piston (inside the bore of the master cylinder) toward the slave cylinder(s) compresses the fluid evenly, but by varying the comparative surface area of the master cylinder and each slave cylinder, one can vary the amount of force and displacement applied to each slave cylinder, relative to the amount of force and displacement applied to the master cylinder. Vehicle applications The most common vehicle uses of master cylinders are in brake and clutch systems. In brake systems, the operated devices are cylinders inside brake calip ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

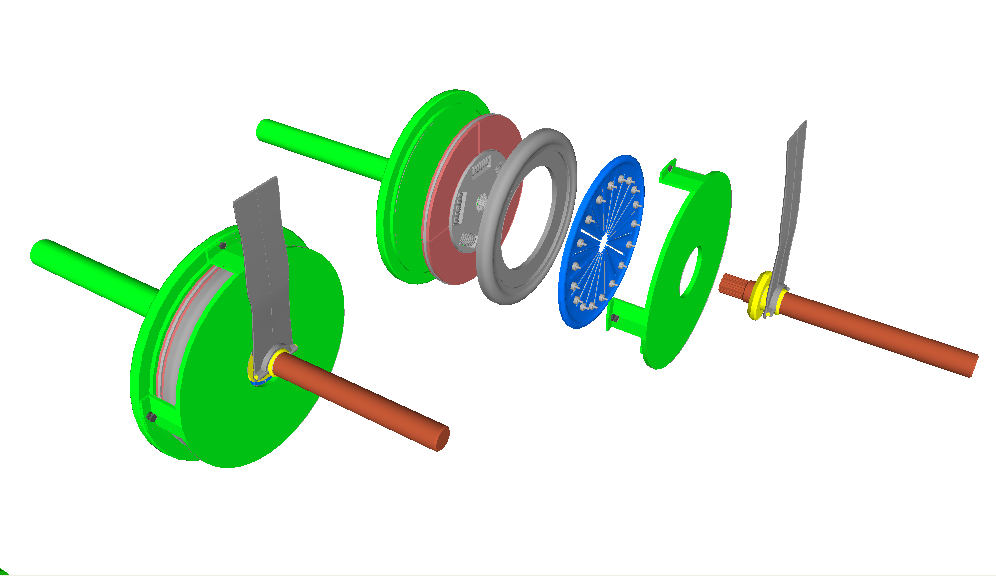

Clutch

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine or other power unit (the driving member), while the other shaft (the driven member) provides output power for work. Typically the motions involved are rotary, but linear clutches also exist. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission, and briefly disconnects, or separates the engine from the transmission system. This disconnects the drive wheels whenever the clutch pedal is depressed, allowing the driver to smoothly change gears. In a torque-controlled drill, for instance, one shaft is driven by a motor, and the other drives a drill chuck. The clutch connects the two shafts so they may be locked together and spin at the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pascal's Law

Pascal's law (also Pascal's principle or the principle of transmission of fluid-pressure) is a principle in fluid mechanics given by Blaise Pascal that states that a pressure change at any point in a confined incompressible fluid is transmitted throughout the fluid such that the same change occurs everywhere. The law was established by French mathematician Blaise Pascal in 1653 and published in 1663. Definition Pascal's principle is defined as This principle is stated mathematically as: : \Delta p =\rho g \cdot\Delta h\, : is the hydrostatic pressure (given in pascals in the SI system), or the difference in pressure at two points within a fluid column, due to the weight of the fluid); :ρ is the fluid density (in kilograms per cubic meter in the SI system); :g is acceleration due to gravity (normally using the sea level acceleration due to Earth's gravity, in meters per second squared); : is the height of fluid above the point of measurement, or the difference in e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake Fluid

Brake fluid is a type of hydraulic fluid used in hydraulic brake and hydraulic clutch applications in automobiles, motorcycles, light trucks, and some bicycles. It is used to transfer force into pressure, and to amplify braking force. It works because liquids are not appreciably compressible. Most brake fluids used today are glycol-ether based, but mineral oil (''Citroën/Rolls-Royce liquide hydraulique minéral'' ( LHM)) and silicone-based (DOT 5) fluids are also available. Standards Most Brake fluids are manufactured to meet standards set by international, national, or local organizations or government agencies. International The International Standards Organisation has published its standard ISO 4925, defining classes 3, 4, and 5, as well as class 5.1, class 6 and class 7 reflecting progressively higher performance for brake fluids. SAE The Society of Automotive Engineers SAE has published standards J1703, J1704, and J1705, reflecting progressively higher performance for b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chassis

A chassis (, ; plural ''chassis'' from French châssis ) is the load-bearing framework of an artificial object, which structurally supports the object in its construction and function. An example of a chassis is a vehicle frame, the underpart of a motor vehicle, on which the body is mounted; if the running gear such as wheels and transmission, and sometimes even the driver's seat, are included, then the assembly is described as a rolling chassis. Examples of use Vehicles In the case of vehicles, the term ''rolling chassis'' means the frame plus the "running gear" like engine, transmission, drive shaft, differential and suspension. An underbody (sometimes referred to as "coachwork"), which is usually not necessary for integrity of the structure, is built on the chassis to complete the vehicle. For commercial vehicles, a rolling chassis consists of an assembly of all the essential parts of a truck without the body to be ready for operation on the road. A car chassis wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device which uses the conservation of angular momentum to store rotational energy; a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical velocity ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thrust Bearing

A thrust bearing is a particular type of rotary bearing. Like other bearings they permanently rotate between parts, but they are designed to support a predominantly axial load. Thrust bearings come in several varieties. *''Thrust ball bearings'', composed of bearing balls supported in a ring, can be used in low thrust applications where there is little axial load. *''Cylindrical thrust roller bearing''s consist of small cylindrical rollers arranged flat with their axes pointing to the axis of the bearing. They give very good carrying capacity and are cheap, but tend to wear due to the differences in radial speed and friction which is higher than with ball bearings. *'' Tapered roller thrust bearings'' consist of small tapered rollers arranged so that their axes all converge at a point on the axis of the bearing. The length of the roller and the diameter of the wide and the narrow ends and the angle of rollers need to be carefully calculated to provide the correct taper so that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake Pad

Brake pads are a component of disc brakes used in automotive and other applications. Brake pads are composed of steel backing plates with friction material bound to the surface that faces the disc brake rotors. Function Brake pads convert the kinetic energy of a vehicle to thermal energy through friction. Two brake pads are contained in the brake with their friction surfaces facing the rotor. When the brakes are hydraulically applied, the caliper clamps or squeezes the two pads together onto the spinning rotor to slow and stop the vehicle. When a brake pad heats up due to contact with the rotor, it transfers small amounts of its friction material onto the disc, leaving a dull grey coating on it. The brake pad and disc (now both having the friction material), then "stick" to each other, providing the friction that stops the vehicle. In disc brakes, there are usually two brake pads per disc rotor, they both function together. These are held in place and actuated by a caliper affixe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wheel Cylinder

A wheel cylinder is a component of a hydraulic drum brake system. It is located in each wheel and is usually positioned at the top of the wheel, above the shoes. Its function is to exert force onto the shoes so as to bring them into contact with the drum and stop the vehicle with friction. The wheel cylinders are usually connected to the shoes with small bird-beak shaped rods. Wheel cylinders were first invented by Bendix in 1958. It is very similar to a slave cylinder In automotive engineering, the master cylinder is a control device that converts force (commonly from a driver's foot) into hydraulic pressure. This device controls slave cylinders located at the other end of the hydraulic brake system. As pi ... and functions in much the same way, internally consisting of only a simple plunger. On older vehicles, these may begin to leak and hinder the performance of the brakes. They are, however, normally inexpensive and relatively easy to replace. The wheel cylinder cons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drum Brakes

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum. The term ''drum brake'' usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a '' clasp brake''. Where the drum is pinched between two shoes, similar to a conventional disc brake, it is sometimes called a ''pinch drum brake'', though such brakes are relatively rare. A related type called a band brake uses a flexible belt or "band" wrapping around the outside of a drum. History The modern automobile drum brake was first used in a car made by Maybach in 1900, although the principle was only later patented in 1902 by Louis Renault. He used woven asbestos lining for the drum brake lining, as no alternative dissipated heat like the asbestos lining, though Maybach had used a less sophisticated drum brake. In the first drum brakes, levers a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake Caliper

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat which must be dispersed. Hydraulically actuated disc brakes are the most commonly used form of brake for motor vehicles, but the principles of a disc brake are applicable to almost any rotating shaft. The components include the disc, master cylinder, and caliper (which contains a cylinder and two brake pads) on both sides of the disc. Design The development of disc-type brakes began in England in the 1890s. In 1902, the Lanchester Motor Company designed brakes that looked and operated in a similar way to a modern disc-brake system even though the disc was thin and a cable activated the brake pad. Other designs were not practical or widely available in cars for another 60 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake

A brake is a mechanical device that inhibits motion by absorbing energy from a moving system. It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction. Background Most brakes commonly use friction between two surfaces pressed together to convert the kinetic energy of the moving object into heat, though other methods of energy conversion may be employed. For example, regenerative braking converts much of the energy to electrical energy, which may be stored for later use. Other methods convert kinetic energy into potential energy in such stored forms as pressurized air or pressurized oil. Eddy current brakes use magnetic fields to convert kinetic energy into electric current in the brake disc, fin, or rail, which is converted into heat. Still other braking methods even transform kinetic energy into different forms, for example by transferring the energy to a rotating flywheel. Brakes are generally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)