|

Manufacturing Process Management

Manufacturing process management (MPM) is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing schedules, and compile cost data. A cornerstone of MPM is the central repository for the integration of all these tools and activities aids in the exploration of alternative production line scenarios; making assembly lines more efficient with the aim of reduced lead time to product launch, shorter product times and reduced work in progress (WIP) inventories as well as allowing rapid response to product or product changes. * Production process planning ** Manufacturing concept planning ** Factory layout planning and analysis *** work flow simulation. *** walk-path assembly planning *** plant design optimization ** Mixed model line balancing. ** Workloads on multiple stations. ** Process simulation tools e.g. die press lines, manufacturin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Enterprise Resource Planning

Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of Business management tools, business management software—typically a suite of integrated application software, applications—that an organization can use to collect, store, manage and interpret data from many business sector, business activities. ERP systems can be local based or Cloud computing, cloud-based. Cloud-based applications have grown in recent years due to information being readily available from any location with Internet access. Traditional On-premises software, on-premise ERP systems are now considered Legacy system, legacy technology. ERP provides an integrated and continuously updated view of core business processes using common databases maintained by a database management system. ERP systems track business resources—cash, raw materials, production capacity—and t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Manufacturing Information

Product and manufacturing information, also abbreviated PMI, conveys non-geometric attributes in 3D computer-aided design (CAD) and Collaborative Product Development systems necessary for manufacturing product components and assemblies. PMI may include geometric dimensions and tolerances, 3D annotation (text) and dimensions, surface finish, and material specifications. PMI is used in conjunction with the 3D model within model-based definition to allow for the elimination of 2D drawings for data set utilization. Uses and visualization The PMI annotation is created on the 3D CAD model, associated to edges and faces, and can be exported into neutral formats such as ISO 10303 STEP and 3D PDF. This information can then be used by a number of down-stream processes. PMI can be used to generate annotation on a traditional 2D drawing the data. However, generally, PMI is used to visualized product definition within the 3D model, thus removing the need for drawings. Some 3D model for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifecycle Management

In industry, Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprises. History The inspiration for the burgeoning business process now known as PLM came from American Motors Corporation (AMC). The automaker was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François Castaing, Vice President for Product Engineering and Development. Lacking the "massive budgets of General Motors, Ford, and foreign competitors … AMC placed R&D emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps)." After introducing its compact Jeep Cherokee (XJ), the vehicle th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Taylor & Francis

Taylor & Francis Group is an international company originating in England that publishes books and academic journals. Its parts include Taylor & Francis, Routledge, F1000 (publisher), F1000 Research or Dovepress. It is a division of Informa, Informa plc, a United Kingdom–based publisher and conference company. Overview The company was founded in 1852 when William Francis (chemist), William Francis joined Richard Taylor (editor), Richard Taylor in his publishing business. Taylor had founded his company in 1798. Their subjects covered agriculture, chemistry, education, engineering, geography, law, mathematics, medicine, and social sciences. Francis's son, Richard Taunton Francis (1883–1930), was sole partner in the firm from 1917 to 1930. In 1965, Taylor & Francis launched Wykeham Publications and began book publishing. T&F acquired Hemisphere Publishing in 1988, and the company was renamed Taylor & Francis Group to reflect the growing number of Imprint (trade name), imp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality Management System

A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction (ISO 9001:2015). It is expressed as the organizational goals and aspirations, policies, processes, documented information, and resources needed to implement and maintain it. Early quality management systems emphasized predictable outcomes of an industrial product production line, using simple statistics and random sampling. By the 20th century, labor inputs were typically the most costly inputs in most industrialized societies, so focus shifted to team cooperation and dynamics, especially the early signaling of problems via a continual improvement cycle. In the 21st century, QMS has tended to converge with sustainability and transparency initiatives, as both investor and customer satisfaction and perceived quality are increasingly tied to these factors. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Management (Project Management)

In civil engineering and project management, process management is the management of "systematic series of activities directed towards causing an end result such that one or more inputs will be acted upon to create one or more outputs".PMI (2012), "Process" definition, in: ''A Guide to the Project Management Body of Knowledge'', 5th Ed. Process management offers project organizations a means of applying the same quality improvement and defect reduction techniques used in business and manufacturing processes by taking a process view of project activity; modeling discrete activities and high-level processes.Mitchell (2016). See Chapter 3 Process Management—Evolution and Definition. Overview The term ''process management'' usually refers to the management of engineering processes and project management processes where a ''process'' is a collection of related, structured tasks that produce a specific service or product to address a certain goal for a particular actor or set of act ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Production Topics

The following outline is provided as an overview of and topical guide to production: Production – act of creating 'use' value or 'utility' that can satisfy a want or need. The act may or may not include factors of production other than labor. Any effort directed toward the realization of a desired product or service is a "productive" effort and the performance of such act is production. The following outline is provided as an overview of and topical guide to production: Types * Industry – production of an economic good or service within an economy. Industry is divided into four sectors, or types of production; they are: Primary sector * Primary sector – this involves the extraction of resources directly from the Earth, this includes agricultural and resource extraction industries. In these industries, the product (that is, the focus of production) is a natural resource. ** Agriculture (outline) – cultivation of animals, plants, fungi, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distributed Control System

A distributed control system (DCS) is a computerised control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control. This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoring and supervision. Distributed control systems first emerged in large, high value, safety critical process industries, and were attractive because the DCS manufacturer would supply both the local control level and central supervisory equipment as an integrated package, thus reducing design integration risk. Today the functionality of Supervisory control and data acquisition (SCADA) and DCS systems are very similar, but DCS tends to be u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Human–machine Interface

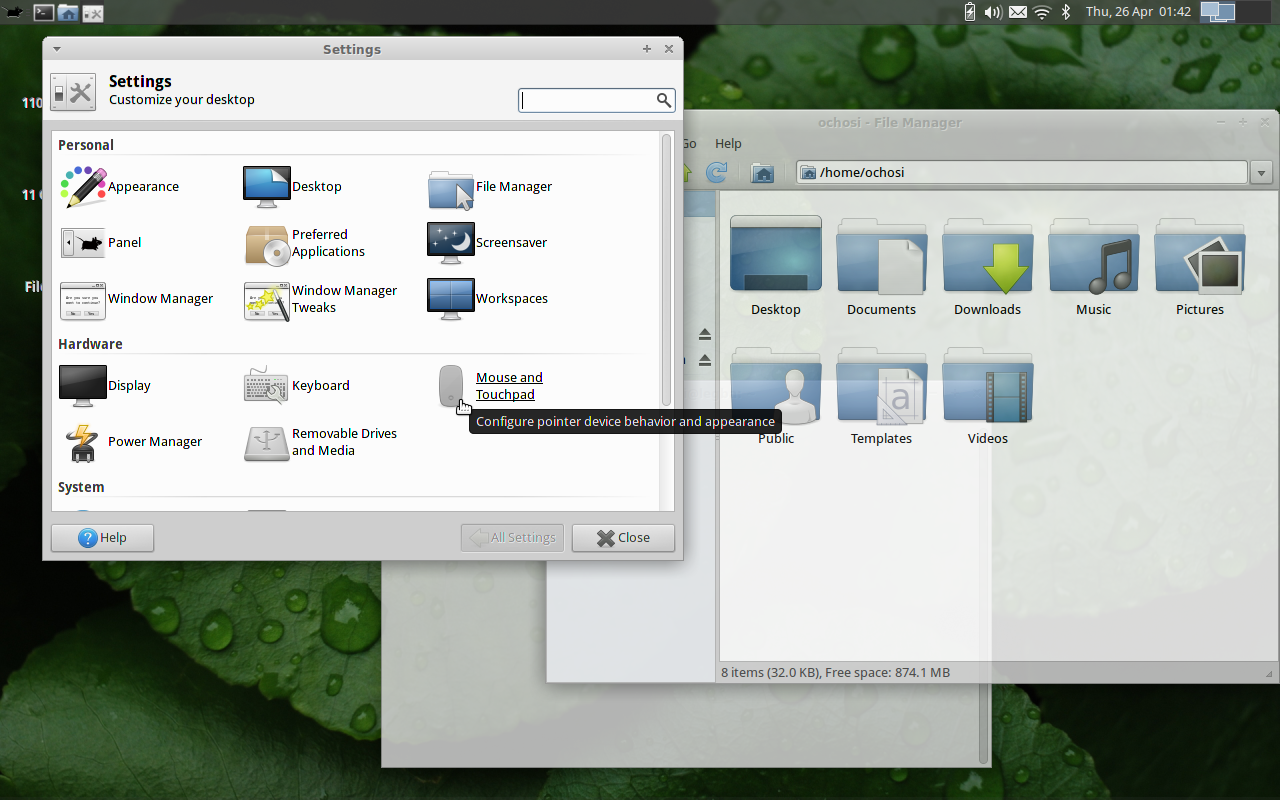

In the industrial design field of human–computer interaction, a user interface (UI) is the space where interactions between humans and machines occur. The goal of this interaction is to allow effective operation and control of the machine from the human end, while the machine simultaneously feeds back information that aids the operators' decision-making process. Examples of this broad concept of user interfaces include the interactive aspects of computer operating systems, hand tools, heavy machinery operator controls and process controls. The design considerations applicable when creating user interfaces are related to, or involve such disciplines as, ergonomics and psychology. Generally, the goal of user interface design is to produce a user interface that makes it easy, efficient, and enjoyable (user-friendly) to operate a machine in the way which produces the desired result (i.e. maximum usability). This generally means that the operator needs to provide minimal input to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SCADA

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery. Explanation The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators. The SCADA concept was developed to be a universal means of remote-access to a variety of local control modules, which could be from different manufacturers and allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Data Management

Product data management (PDM) should not be confused with product information management (PIM). PDM is the name of a business function within product lifecycle management (PLM) that is denotes the management and publication of product data. In software engineering, this is known as version control. The goals of product data management include ensuring all stakeholders share a common understanding, that confusion during the execution of the processes is minimized, and that the highest standards of quality controls are maintained. Introduction Product data management is the use of software or other tools to track and control data related to a particular product. The data tracked usually involves the technical specifications of the product, specifications for manufacture and development, and the types of materials that will be required to produce goods. The use of product data management allows a company to track the various costs associated with the creation and launch of a product. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Operations Management

Manufacturing operations management (MOM) is a collection of systems for managing end-to-end manufacturing processes with a view to optimizing efficiency. There are many types of MOM software, including for production management, performance analysis, quality and compliance, and human machine interface (HMI). Production management software provides real-time information about jobs and orders, labor and materials, machine status, and product shipments. Performance analysis software displays metrics at the machine, line, plant and enterprise level for situational or historical analysis. Quality and compliance software is used to promote compliance with standards and specifications for operational processes and procedures. HMI software is a form of manufacturing operations management (MOM) software that enables operators to manage industrial and process control machinery using a computer-based interface. Emerging Software Trends Advancements in technology and market demands are enabl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)