|

Machinist Square

A machinist square or engineer's square is the metalworkers' equivalent of a try square. It consists of a steel blade inserted and either welded or pinned into a heavier body at an angle of 90°. Usually a small notch is present at the inside corner of the square. This prevents small particles from accumulating at the juncture and affecting the square's reading. Use In use, the body is aligned against the one edge of the object and the blade is presented to the end or body of the object. If the end is being checked, then a strong light source behind the square will show any mismatch between the blade of the square and the end of the object. The purpose of this action is to check for squareness or to mark out the body of the workpiece. Accuracy Machinist squares can have a linear error of no greater than 0.0002 in/in.. Squares must be occasionally checked for accuracy. The four disk method is one way to verify overall squareness. However, it cannot detect bent blades. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Try Square

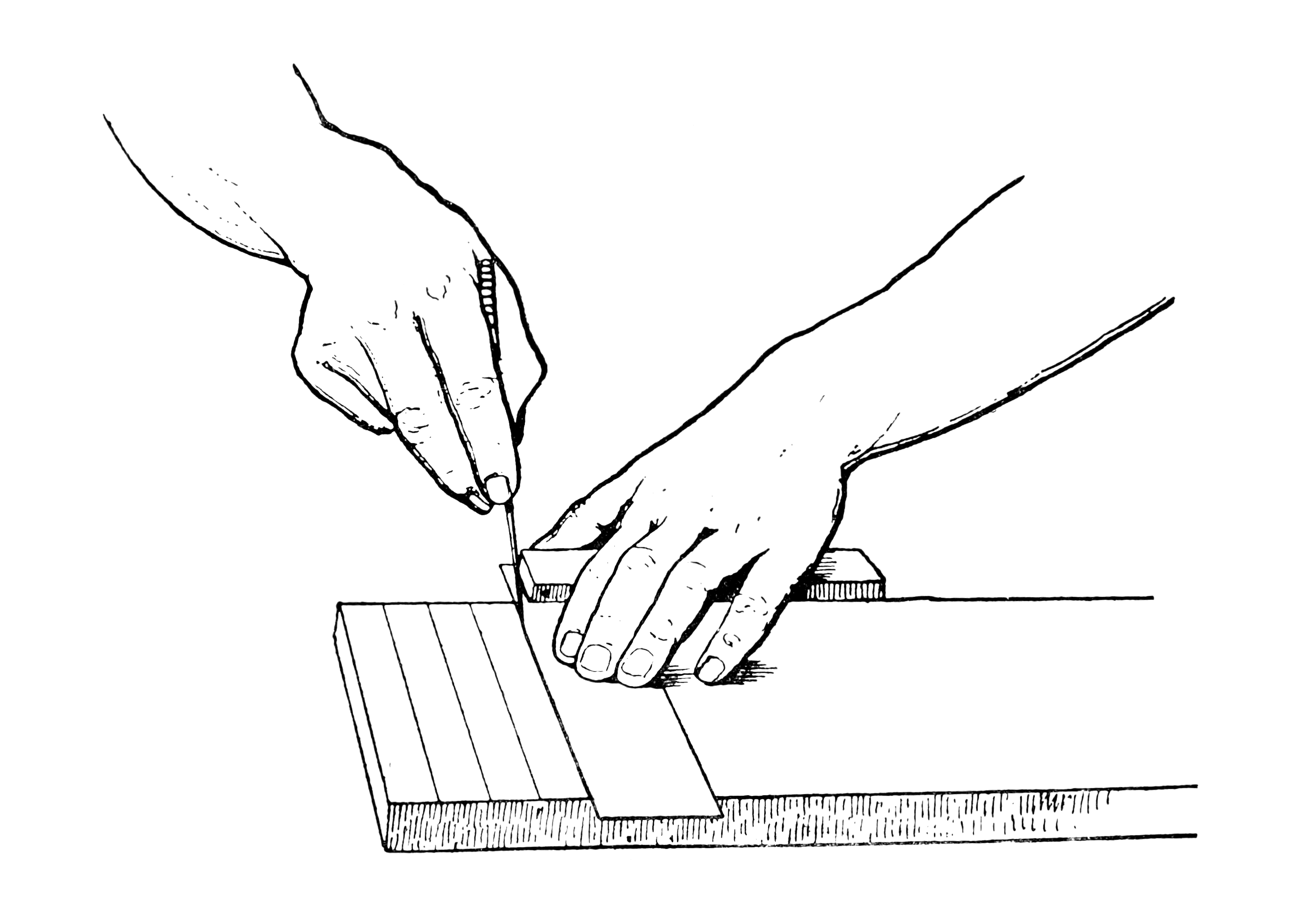

A try square or try-square is a woodworking tool used for marking and checking 90° angles on pieces of wood. Though woodworkers use many different Square (tool), types of square, the try square is considered one of the essential tools for woodworking. The ''square'' in the name refers to the Right angle, 90° angle. To ''try'' a piece of wood is to check if the edges and faces are straight, flat, and square to one another. A ''try square'' is so called because it is used to ''try'' how ''square'' the workpiece is. Description A try square is made of two key parts, the ''blade'' (also known as a ''beam'' or ''tongue'') and the ''stock'', which are fixed together at 90° to form an 'L' shape. The blade is usually made of wood or steel and is fixed into the stock, which is usually thicker than the blade and made of wood, metal or plastic. Both the stock and the tongue are usually made with parallel edges. Typically the blade and the stock will be rectangular in profile, though on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welded

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often an indust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rivet

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched or drilled hole, and the tail is ''upset'', or ''bucked'' (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the ''factory head'' and the deformed end is called the ''shop head'' or buck-tail. Because there is effectively a head on each end of an installed rivet, it can support tension loads. However, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft). Fastenings used in traditional w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angle

In Euclidean geometry, an angle is the figure formed by two Ray (geometry), rays, called the ''Side (plane geometry), sides'' of the angle, sharing a common endpoint, called the ''vertex (geometry), vertex'' of the angle. Angles formed by two rays lie in the plane (geometry), plane that contains the rays. Angles are also formed by the intersection of two planes. These are called dihedral angles. Two intersecting curves may also define an angle, which is the angle of the rays lying tangent to the respective curves at their point of intersection. ''Angle'' is also used to designate the measurement, measure of an angle or of a Rotation (mathematics), rotation. This measure is the ratio of the length of a arc (geometry), circular arc to its radius. In the case of a geometric angle, the arc is centered at the vertex and delimited by the sides. In the case of a rotation, the arc is centered at the center of the rotation and delimited by any other point and its image by the rotation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Marking Out

Marking out or layout means the process of transferring a design or pattern to a workpiece, as the first step in the manufacturing process. It is performed in many industries or hobbies although in the repetition industries the machine's initial setup is designed to remove the need to mark out every individual piece. Manufacturing Marking out consists of transferring the dimensions from the plan to the workpiece in preparation for the next step, machining or manufacture. Typical tools include: * Surface plate or ''marking out table'' — provides a true surface from which to work * Angle plates — assist in holding the workpiece perpendicular to the table * Scriber — is the equivalent of a pen or pencil. It literally scratches the metal surface leaving behind a fine, bright line * Height gauge or ''scribing block'' — allows lines to be scribed at a preset distance, from the tables surface * Surface gauge — an ungraduated comparison measuring tool that pe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Square Check

In Euclidean geometry, a square is a regular quadrilateral, which means that it has four equal sides and four equal angles (90-degree angles, π/2 radian angles, or right angles). It can also be defined as a rectangle with two equal-length adjacent sides. It is the only regular polygon whose internal angle, central angle, and external angle are all equal (90°), and whose diagonals are all equal in length. A square with vertices ''ABCD'' would be denoted . Characterizations A convex quadrilateral is a square if and only if it is any one of the following: * A rectangle with two adjacent equal sides * A rhombus with a right vertex angle * A rhombus with all angles equal * A parallelogram with one right vertex angle and two adjacent equal sides * A quadrilateral with four equal sides and four right angles * A quadrilateral where the diagonals are equal, and are the perpendicular bisectors of each other (i.e., a rhombus with equal diagonals) * A convex quadrilateral with successiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Square (tool)

A square is a tool used for marking and referencing a Right angle, 90° angle, though Miter square, mitre squares are used for 45° angles. Squares see common use in woodworking, metalworking, construction and technical drawing. Some squares incorporate a scale for measuring distances (a ruler) or for calculating angles. Terminology Many squares are made of two parts, a ''stock'' and a straight ''blade'' or ''tongue''. The stock is usually thicker than the blade, with the blade being fixed into or onto the stock. The blade typically has parallel edges. The stock is usually held against the edge of a workpiece or drawing board and the tongue is then used as a straight edge for making a mark, or as a reference to check the accuracy of an angle. History Wooden Try square, try squares have survived from Ancient Egyptian technology, Ancient Egypt and Roman technology, Ancient Rome and can be seen in art from the time. From the 18th century squares began to be manufactured in Fact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Testing A Try Square For Accuracy

An examination (exam or evaluation) or test is an educational assessment intended to measure a test-taker's knowledge Knowledge can be defined as awareness of facts or as practical skills, and may also refer to familiarity with objects or situations. Knowledge of facts, also called propositional knowledge, is often defined as true belief that is distinc ..., skill, aptitude, physical fitness, or classification in many other topics (e.g., beliefs). A test may be administered verbally, on paper, on a computer-adaptive testing, computer, or in a predetermined area that requires a test taker to demonstrate or perform a set of skills. Tests vary in style, rigor and requirements. There is no general consensus or invariable standard for test formats and difficulty. Often, the format and difficulty of the test is dependent upon the educational philosophy of the instructor, subject matter, class size, policy of the educational institution, and requirements of accreditation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |