|

Microreactor

A microreactor or microstructured reactor or microchannel reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels.''Recent advances in synthetic micro reaction technology'' Paul Watts and Charlotte Wiles Chem. Commun., 2007, 443 - 467, Microreactors are studied in the field of micro process engineering, together with other devices (such as micro heat exchangers) in which physical processes occur. The microreactor is usually a continuous flow reactor (contrast with/to a batch reactor). Microreactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control. History Gas-phase microreactors have a long history but those involving liquids started to appear in the late 1990s. On ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuous Flow Reactor

In flow chemistry, a chemical reaction is run in a continuously flowing stream rather than in batch production. In other words, pumps move fluid into a reactor, and where tubes join one another, the fluids contact one another. If these fluids are reactive, a reaction takes place. Flow chemistry is a well-established technique for use at a large scale when manufacturing large quantities of a given material. However, the term has only been coined recently for its application on a laboratory scale by chemists and describes small pilot plants, and lab-scale continuous plants. Often, microreactors are used. Batch vs. flow Comparing parameter definitions in Batch vs Flow *Reaction stoichiometry: In batch production this is defined by the concentration of chemical reagents and their volumetric ratio. In flow this is defined by the concentration of reagents and the ratio of their flow rate. *Residence time: In batch production this is determined by how long a vessel is held at a give ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micro Process Engineering

{{Unreferenced, date=June 2019, bot=noref (GreenC bot) Micro process engineering is the science of conducting chemical or physical processes (unit operations) inside small volumina, typically inside channels with diameters of less than 1 mm (microchannels) or other structures with sub-millimeter dimensions. These processes are usually carried out in continuous flow mode, as opposed to batch production, allowing a throughput high enough to make micro process engineering a tool for chemical production. Micro process engineering is therefore not to be confused with microchemistry, which deals with very small overall quantities of matter. The subfield of micro process engineering that deals with chemical reactions, carried out in microstructured reactors or " microreactors", is also known as microreaction technology. The unique advantages of microstructured reactors or '' microreactors'' are enhanced heat transfer due to the large surface area-to-volume ratio, and enhanced mass ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microreaction Technology

{{Unreferenced, date=June 2019, bot=noref (GreenC bot) Micro process engineering is the science of conducting chemical or physical processes (unit operations) inside small volumina, typically inside channels with diameters of less than 1 mm (microchannels) or other structures with sub-millimeter dimensions. These processes are usually carried out in continuous flow mode, as opposed to batch production, allowing a throughput high enough to make micro process engineering a tool for chemical production. Micro process engineering is therefore not to be confused with microchemistry, which deals with very small overall quantities of matter. The subfield of micro process engineering that deals with chemical reactions, carried out in microstructured reactors or "microreactors", is also known as microreaction technology. The unique advantages of microstructured reactors or ''microreactors'' are enhanced heat transfer due to the large surface area-to-volume ratio, and enhanced mass t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micro Heat Exchanger

Micro heat exchangers, Micro-scale heat exchangers, or microstructured heat exchangers are heat exchangers in which (at least one) fluid flows in lateral confinements with typical dimensions below 1 mm. The most typical such confinement are microchannel (microtechnology), microchannels, which are channels with a hydraulic diameter below 1 mm. Microchannel heat exchangers can be made from metal or ceramic. Microchannel heat exchangers can be used for many applications including: * high-performance aircraft gas turbine engines * heat pumps * Microprocessor and microchip cooling * air conditioning Background Investigation of microscale thermal devices is motivated by the single phase internal flow correlation for convective heat transfer: :h=\mathit_c \frac Where h is the heat transfer coefficient, \mathit_c is the Nusselt number, k is the thermal conductivity of the fluid and d is the hydraulic diameter of the channel or duct. In internal laminar flows, the Nusselt number b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micro Heat Exchanger

Micro heat exchangers, Micro-scale heat exchangers, or microstructured heat exchangers are heat exchangers in which (at least one) fluid flows in lateral confinements with typical dimensions below 1 mm. The most typical such confinement are microchannel (microtechnology), microchannels, which are channels with a hydraulic diameter below 1 mm. Microchannel heat exchangers can be made from metal or ceramic. Microchannel heat exchangers can be used for many applications including: * high-performance aircraft gas turbine engines * heat pumps * Microprocessor and microchip cooling * air conditioning Background Investigation of microscale thermal devices is motivated by the single phase internal flow correlation for convective heat transfer: :h=\mathit_c \frac Where h is the heat transfer coefficient, \mathit_c is the Nusselt number, k is the thermal conductivity of the fluid and d is the hydraulic diameter of the channel or duct. In internal laminar flows, the Nusselt number b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Institute For Micro Process Engineering

The Institute for Micro Process Engineering IMVT (from the German name '' Institut für Mikroverfahrenstechnik'') is an institute within the Karlsruhe Research Center (''Forschungszentrum Karlsruhe'') in Eggenstein-Leopoldshafen, Germany. Its main field of activity is micro process engineering, the science of conducting chemical and/or physical processes in confines with typical dimensions below 1 mm. History and Organization The IMVT was formally established in July 2001 and continued previous activities in micro process engineering carried out by the Central Experimentation Department (''Hauptabteilung Versuchstechnik'', HVT) at the Karlsruhe Research Center. Its first director was Klaus Schubert. Between 1997 and 2001 the first activities, which were focused on developing and testing micro heat exchangers, were expanded by a new group (Head: Maximilian Fichtner) to chemical process engineering in microchannels, with a focus on fuel processing (methanol steam reforming, p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reagent

In chemistry, a reagent ( ) or analytical reagent is a substance or compound added to a system to cause a chemical reaction, or test if one occurs. The terms ''reactant'' and ''reagent'' are often used interchangeably, but reactant specifies a substance ''consumed'' in the course of a chemical reaction. ''Solvents'', though involved in the reaction mechanism, are usually not called reactants. Similarly, ''catalysts'' are not consumed by the reaction, so they are not reactants. In biochemistry, especially in connection with enzyme-catalyzed reactions, the reactants are commonly called substrates. Definitions Organic chemistry In organic chemistry, the term "reagent" denotes a chemical ingredient (a compound or mixture, typically of inorganic or small organic molecules) introduced to cause the desired transformation of an organic substance. Examples include the Collins reagent, Fenton's reagent, and Grignard reagents. Analytical chemistry In analytical chemistry, a reagent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Kinetics

Chemical kinetics, also known as reaction kinetics, is the branch of physical chemistry that is concerned with understanding the rates of chemical reactions. It is to be contrasted with chemical thermodynamics, which deals with the direction in which a reaction occurs but in itself tells nothing about its rate. Chemical kinetics includes investigations of how experimental conditions influence the speed of a chemical reaction and yield information about the reaction's mechanism and transition states, as well as the construction of mathematical models that also can describe the characteristics of a chemical reaction. History In 1864, Peter Waage and Cato Guldberg pioneered the development of chemical kinetics by formulating the law of mass action, which states that the speed of a chemical reaction is proportional to the quantity of the reacting substances.C.M. Guldberg and P. Waage,"Studies Concerning Affinity" ''Forhandlinger i Videnskabs-Selskabet i Christiania'' (1864), 35P. W ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Operating Temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the maximum operating temperature (or peak operating temperature). Outside this range of safe operating temperatures the device may fail. It is one component of reliability engineering. Similarly, biological systems have a viable temperature range, which might be referred to as an "operating temperature". Ranges Most devices are manufactured in several temperature grades. Broadly accepted grades are: *Commercial: 0 ° to 70 °C *Industrial: −40 ° to 85 °C *Military: −55 ° to 125 °C Nevertheless, each manufacturer defines its own temperature grades so designers must pay close attention to actual datasheet spe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work-up (chemistry)

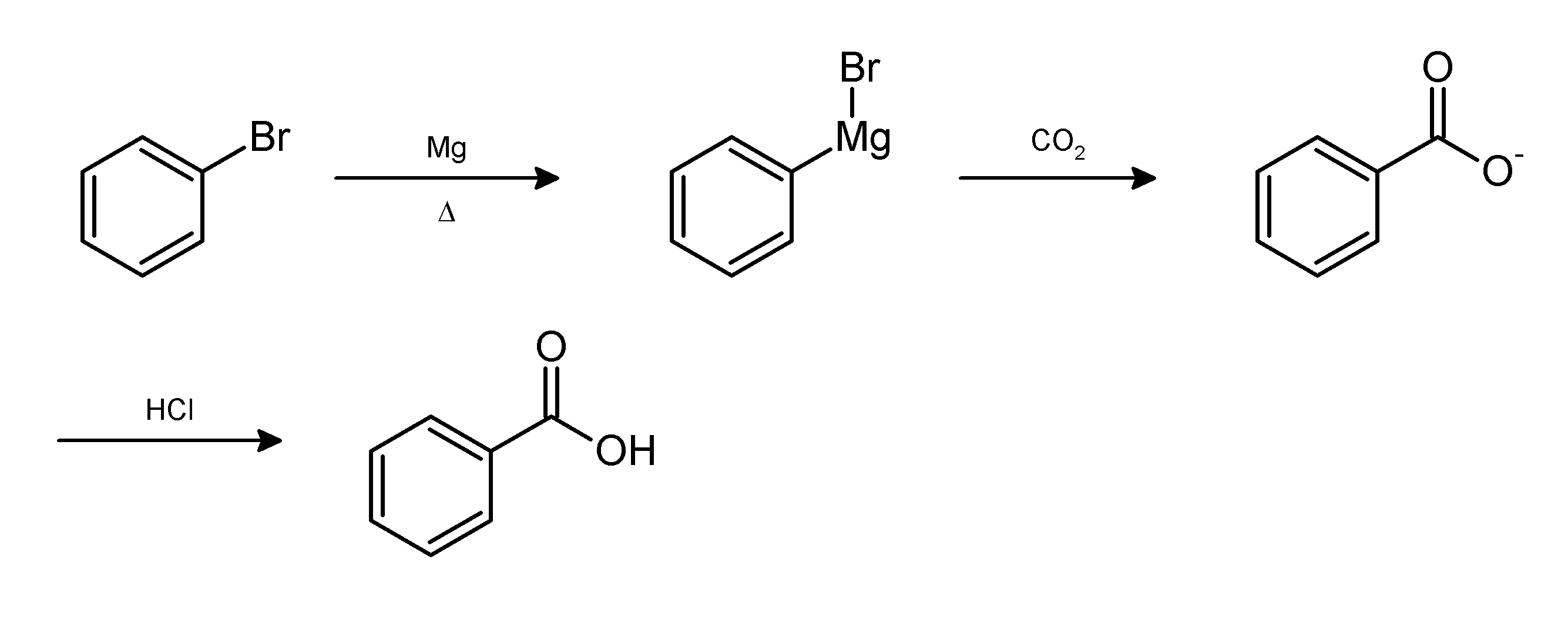

In chemistry, work-up refers to the series of manipulations required to isolate and purify the product(s) of a chemical reaction. Typically, these manipulations may include: * quenching a reaction to deactivate any unreacted reagents. * cooling the reaction mixture or adding an ''antisolvent'' to induce precipitation, and collecting or removing the solids by filtration, decantation, or centrifugation * removal of solvents by evaporation * separating the reaction mixture into organic and aqueous layers by liquid-liquid extraction * purification by chromatography, distillation or recrystallization For example, the Grignard reaction between phenylmagnesium bromide and carbon dioxide in the form of dry ice gives the conjugate base of benzoic acid. The desired product, benzoic acid, is obtained by the following work-up:{{cite book , title = Introduction to Organic Laboratory Techniques: A Small Scale Approach , author = Donald L. Pavia , year = 2004 , publisher = Thomson Brooks ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electroosmotic Flow

Electroosmotic flow (or electro-osmotic flow, often abbreviated EOF; synonymous with electroosmosis or electroendosmosis) is the motion of liquid induced by an applied potential across a porous material, capillary tube, membrane, microchannel, or any other fluid conduit. Because electroosmotic velocities are independent of conduit size, as long as the electrical double layer is much smaller than the characteristic length scale of the channel, electroosmotic flow will have little effect. Electroosmotic flow is most significant when in small channels. Electroosmotic flow is an essential component in chemical separation techniques, notably capillary electrophoresis. Electroosmotic flow can occur in natural unfiltered water, as well as buffered solutions. History Electro-osmotic flow was first reported in 1807 by Ferdinand Friedrich Reuss (18 February 1778 (Tübingen, Germany) – 14 April 1852 (Stuttgart, Germany)) in an unpublished lecture before the Physical-Medical Society of Mos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |