|

Logistics Engineering

Logistics engineering is a field of engineering dedicated to the scientific organization of the purchase, transport, storage, distribution, and warehousing of materials and finished goods. Logistics engineering is a complex science that considers trade-offs in component/system design, repair capability, training, spares inventory, demand history, storage and distribution points, transportation methods, etc., to ensure the "thing" is where it's needed, when it's needed, and operating the way it's needed all at an acceptable cost. Overview Logistics is generally concerned with cost centre service activities, but provides value via improved efficiency and customer satisfaction. It can quickly lose that value if the customer becomes dissatisfied. The end customer can include another process or work center inside of the manufacturing facility, a warehouse where items are stocked or the final customer who will use the product. Another approach which has appeared in recent years is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Purchase

Purchasing is the process a business or organization uses to acquire goods or services to accomplish its goals. Although there are several organizations that attempt to set standards in the purchasing process, processes can vary greatly between organizations. Purchasing is part of the wider procurement process, which typically also includes expediting, supplier quality, transportation, and logistics. Details Purchasing managers/directors, and procurement managers/directors guide the organization’s acquisition procedures and standards. Most organizations use a three-way check as the foundation of their purchasing programs. This involves three departments in the organization completing separate parts of the acquisition process. The three departments do not all report to the same senior manager, to prevent unethical practices and lend credibility to the process. These departments can be purchasing, receiving and accounts payable; or engineering, purchasing and accounts payab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reliability Engineering

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time. The reliability function is theoretically defined as the probability of success at time t, which is denoted R(t). This probability is estimated from detailed (physics of failure) analysis, previous data sets or through reliability testing and reliability modelling. Availability, testability, maintainability and maintenance, repair and operations, maintenance are often defined as a part of "reliability engineering" in reliability programs. Reliability often plays the key role in the cost-effectiveness of systems. Reliability engineering deals with the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Demand Forecasting

Demand forecasting is known as the process of making future estimations in relation to customer demand over a specific period. Generally, demand forecasting will consider historical data and other analytical information to produce the most accurate predictions. More specifically, the methods of demand forecasting entails using predictive analytics of historical data to understand and predict customer demand in order to understand key economic conditions and assist in making crucial supply decisions to optimise business profitability. Demand forecasting methods are divided into two major categories, qualitative and quantitative methods. Qualitative methods are based on expert opinion and information gathered from the field. It is mostly used in situations when there is minimal data available to analyse. For example, when a business or product is newly being introduced to the market. Quantitative methods however, use data, and analytical tools in order to create predictions. Demand f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Outsourcing

Outsourcing is an agreement in which one company hires another company to be responsible for a planned or existing activity which otherwise is or could be carried out internally, i.e. in-house, and sometimes involves transferring employees and assets from one firm to another. The term ''outsourcing'', which came from the phrase ''outside resourcing'', originated no later than 1981. The concept, which ''The Economist'' says has "made its presence felt since the time of the Second World War", often involves the contracting of a business process (e.g., payroll processing, claims processing), operational, and/or non-core functions, such as manufacturing, facility management, call center/call center support. The practice of handing over control of public services to private enterprises (privatization), even if conducted on a limited, short-term basis, may also be described as outsourcing. Outsourcing includes both foreign and domestic contracting, and sometimes includes offshoring ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Purchasing

Purchasing is the process a business or organization uses to acquire goods or services to accomplish its goals. Although there are several organizations that attempt to set standards in the purchasing process, processes can vary greatly between organizations. Purchasing is part of the wider procurement process, which typically also includes expediting, supplier quality, transportation, and logistics. Details Purchasing managers/directors, and procurement managers/directors guide the organization’s acquisition procedures and standards. Most organizations use a three-way check as the foundation of their purchasing programs. This involves three departments in the organization completing separate parts of the acquisition process. The three departments do not all report to the same senior manager, to prevent unethical practices and lend credibility to the process. These departments can be purchasing, receiving and accounts payable; or engineering, purchasing and accounts paya ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Customer Service

Customer service is the assistance and advice provided by a company to those people who buy or use its products or services. Each industry requires different levels of customer service, but in the end, the idea of a well-performed service is that of increasing revenues. The perception of success of the customer service interactions is dependent on employees "who can adjust themselves to the personality of the customer". Customer service is often practiced in a way that reflects the strategies and values of a firm. Good quality customer service is usually measured through customer retention. Customer service for some firms is part of the firm’s intangible assets and can differentiate it from others in the industry. One good customer service experience can change the entire perception a customer holds towards the organization. Customer service does not only focus on the external aspect of the organization, but also the internal relations that facilitate the business activity. For ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Business Logistics

Logistics is generally the detailed organization and implementation of a complex operation. In a general business sense, logistics manages the flow of goods between the point of origin and the point of consumption to meet the requirements of customers or corporations. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items. In military science, logistics is concerned with maintaining army supply lines while disrupting those of the enemy, since an armed force without resources and transportation is defenseless. Military logistics was already practiced in the ancient world and as the modern military has a significant need for logistics solutions, advanced implementations have been developed. In military logistics, logistics officers manage how and when to move resources to the places they are needed. Logistics management is the part of supply chain management and supply chain engine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Queueing Theory

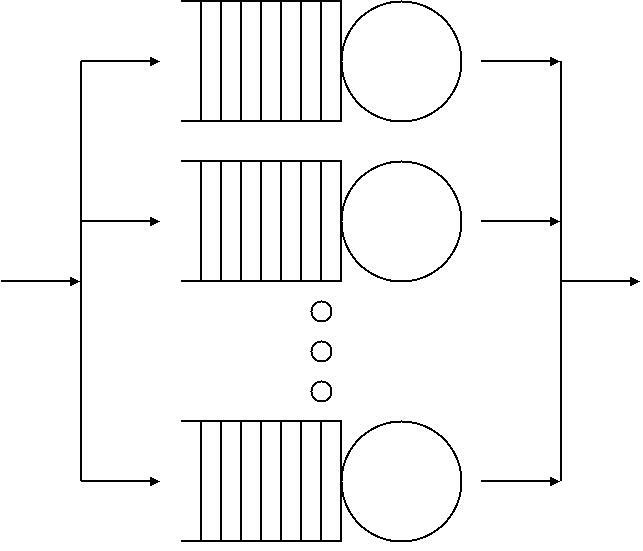

Queueing theory is the mathematical study of waiting lines, or queues. A queueing model is constructed so that queue lengths and waiting time can be predicted. Queueing theory is generally considered a branch of operations research because the results are often used when making business decisions about the resources needed to provide a service. Queueing theory has its origins in research by Agner Krarup Erlang when he created models to describe the system of Copenhagen Telephone Exchange company, a Danish company. The ideas have since seen applications including telecommunication, traffic engineering, computing and, particularly in industrial engineering, in the design of factories, shops, offices and hospitals, as well as in project management. Spelling The spelling "queueing" over "queuing" is typically encountered in the academic research field. In fact, one of the flagship journals of the field is ''Queueing Systems''. Single queueing nodes A queue, or queueing node ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Statistical Distribution

In statistics, an empirical distribution function (commonly also called an empirical Cumulative Distribution Function, eCDF) is the distribution function associated with the empirical measure of a sample. This cumulative distribution function is a step function that jumps up by at each of the data points. Its value at any specified value of the measured variable is the fraction of observations of the measured variable that are less than or equal to the specified value. The empirical distribution function is an estimate of the cumulative distribution function that generated the points in the sample. It converges with probability 1 to that underlying distribution, according to the Glivenko–Cantelli theorem. A number of results exist to quantify the rate of convergence of the empirical distribution function to the underlying cumulative distribution function. Definition Let be independent, identically distributed real random variables with the common cumulative distribu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study. A few different types of FMEA analyses exist, such as: * Functional * Design * Process Sometime ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mean Time To Repair

Mean time to repair (MTTR) is a basic measure of the maintainability of repairable items. It represents the average time required to repair a failed component or device. Expressed mathematically, it is the total corrective maintenance time for failures divided by the total number of corrective maintenance actions for failures during a given period of time. It generally does not include lead time for parts not readily available or other Administrative or Logistic Downtime (ALDT). In fault-tolerant design, MTTR is usually considered to also include the time the fault is latent (the time from when the failure occurs until it is detected). If a latent fault goes undetected until an independent failure occurs, the system may not be able to recover. MTTR is often part of a maintenance contract, where a system whose MTTR is 24 hours is generally more valuable than for one of 7 days if mean time between failures is equal, because its Operational Availability is higher. However, in th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mean Time Between Failures

Mean time between failures (MTBF) is the predicted elapsed time between inherent failures of a mechanical or electronic system during normal system operation. MTBF can be calculated as the arithmetic mean (average) time between failures of a system. The term is used for repairable systems while mean time to failure (MTTF) denotes the expected time to failure for a non-repairable system. The definition of MTBF depends on the definition of what is considered a failure. For complex, repairable systems, failures are considered to be those out of design conditions which place the system out of service and into a state for repair. Failures which occur that can be left or maintained in an unrepaired condition, and do not place the system out of service, are not considered failures under this definition. In addition, units that are taken down for routine scheduled maintenance or inventory control are not considered within the definition of failure. The higher the MTBF, the longer a system ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)