|

Lampwork

Lampworking is a type of glasswork in which a torch or lamp is used to melt the glass. Once in a molten state, the glass is formed by blowing and shaping with tools and hand movements. It is also known as flameworking or torchworking, as the modern practice no longer uses oil-fueled lamps. Although lack of a precise definition for lampworking makes it difficult to determine when this technique was first developed, the earliest verifiable lampworked glass is probably a collection of beads thought to date to the fifth century BC. Lampworking became widely practiced in Murano, Italy in the 14th century. As early as the 17th century, itinerant glassworkers demonstrated lampworking to the public. In the mid-19th century lampwork technique was extended to the production of paperweights, primarily in France, where it became a popular art form, still collected today. Lampworking differs from glassblowing in that glassblowing uses a furnace as the primary heat source, although torches are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lampwork Glass Eye Cabochon Tutorial Boro

Lampworking is a type of glasswork in which a torch or lamp is used to melt the glass. Once in a molten state, the glass is formed by blowing and shaping with tools and hand movements. It is also known as flameworking or torchworking, as the modern practice no longer uses oil-fueled lamps. Although lack of a precise definition for lampworking makes it difficult to determine when this technique was first developed, the earliest verifiable lampworked glass is probably a collection of beads thought to date to the fifth century BC. Lampworking became widely practiced in Murano, Italy in the 14th century. As early as the 17th century, itinerant glassworkers demonstrated lampworking to the public. In the mid-19th century lampwork technique was extended to the production of paperweights, primarily in France, where it became a popular art form, still collected today. Lampworking differs from glassblowing in that glassblowing uses a furnace as the primary heat source, although torches are a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lampworking

Lampworking is a type of glasswork in which a torch or lamp is used to melt the glass. Once in a molten state, the glass is formed by blowing and shaping with tools and hand movements. It is also known as flameworking or torchworking, as the modern practice no longer uses oil-fueled lamps. Although lack of a precise definition for lampworking makes it difficult to determine when this technique was first developed, the earliest verifiable lampworked glass is probably a collection of beads thought to date to the fifth century BC. Lampworking became widely practiced in Murano, Italy in the 14th century. As early as the 17th century, itinerant glassworkers demonstrated lampworking to the public. In the mid-19th century lampwork technique was extended to the production of paperweights, primarily in France, where it became a popular art form, still collected today. Lampworking differs from glassblowing in that glassblowing uses a furnace as the primary heat source, although torches are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lampwork2

Lampworking is a type of glasswork in which a torch or lamp is used to melt the glass. Once in a molten state, the glass is formed by blowing and shaping with tools and hand movements. It is also known as flameworking or torchworking, as the modern practice no longer uses oil-fueled lamps. Although lack of a precise definition for lampworking makes it difficult to determine when this technique was first developed, the earliest verifiable lampworked glass is probably a collection of beads thought to date to the fifth century BC. Lampworking became widely practiced in Murano, Italy in the 14th century. As early as the 17th century, itinerant glassworkers demonstrated lampworking to the public. In the mid-19th century lampwork technique was extended to the production of paperweights, primarily in France, where it became a popular art form, still collected today. Lampworking differs from glassblowing in that glassblowing uses a furnace as the primary heat source, although torches are a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Borosilicate

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about . It is commonly used for the construction of reagent bottles and flasks as well as lighting, electronics, and cookware. Borosilicate glass is sold under various trade names, including Borosil, Duran, Pyrex, Glassco, Supertek, Suprax, Simax, Bellco, Marinex (Brazil), BSA 60, BSC 51 (by NIPRO), Heatex, Endural, Schott, Refmex, Kimax, Gemstone Well, and MG (India). Single ended self-starting lamps are insulated with a mica disc and contained in a borosilicate glass gas discharge tube (arc tube) and a metal cap. They include the sodium-vapor lamp that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Borosilicate Glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about . It is commonly used for the construction of reagent bottles and flasks as well as lighting, electronics, and cookware. Borosilicate glass is sold under various trade names, including Borosil, Duran, Pyrex, Glassco, Supertek, Suprax, Simax, Bellco, Marinex (Brazil), BSA 60, BSC 51 (by NIPRO), Heatex, Endural, Schott, Refmex, Kimax, Gemstone Well, and MG (India). Single ended self-starting lamps are insulated with a mica disc and contained in a borosilicate glass gas discharge tube (arc tube) and a metal cap. They include the sodium-vapor lamp tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paperweight

A paperweight is a small solid object heavy enough, when placed on top of papers, to keep them from blowing away in a breeze or from moving under the strokes of a painting brush (as with Chinese calligraphy). While any object, such as a stone, can serve as a paperweight, decorative paperweights of glass are produced, either by individual artisans or factories, usually in limited editions, and are collected as works of fine glass art, some of which are exhibited in museums. First produced in about 1845, particularly in France, such decorative paperweights declined in popularity before undergoing a revival in the mid-twentieth century. Basic features Decorative glass paperweights have a flat or slightly concave base, usually polished but sometimes frosted, cut glass, cut in one of several variations (e.g. star-cut bases have a multi-pointed star, while a diamond cut base has grooves cut in a criss-cross pattern), although a footed weight has a flange in the base. The ground on w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glassblowing

Glassblowing is a glassforming technique that involves inflating molten glass into a bubble (or parison) with the aid of a Blowpipe (tool), blowpipe (or blow tube). A person who blows glass is called a ''glassblower'', ''glassmith'', or ''gaffer''. A ''lampworking, lampworker'' (often also called a glassblower or glassworker) manipulates glass with the use of a torch on a smaller scale, such as in producing precision laboratory glassware out of borosilicate glass. Technology Principles As a novel glass forming technique created in the middle of the 1st century BC, glassblowing exploited a working property of glass that was previously unknown to glassworkers; inflation, which is the expansion of a molten blob of glass by introducing a small amount of air into it. That is based on the liquid structure of glass where the atoms are held together by strong chemical bonds in a disordered and random network,Frank, S 1982. Glass and Archaeology. Academic Press: London. Freestone, I. (1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead Glass

Lead glass, commonly called crystal, is a variety of glass in which lead replaces the calcium content of a typical potash glass. Lead glass contains typically 18–40% (by weight) lead(II) oxide (PbO), while modern lead crystal, historically also known as flint glass due to the original silica source, contains a minimum of 24% PbO. Lead glass is often desirable for a variety of uses due to its clarity. The term ''lead crystal'' is, technically, not an accurate term to describe lead glass, because glass lacks a crystalline structure and is instead an amorphous solid. The use of the term ''lead crystal'' or just "crystal" remains popular for historical and commercial reasons, and because "lead" sounds toxic to consumers. It is retained from the Venetian word ''cristallo'' to describe the rock crystal imitated by Murano glassmakers. This naming convention has been maintained to the present day to describe decorative hollow-ware. Lead crystal glassware was formerly used to store a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annealing (glass)

Annealing is a process of slowly cooling hot glass objects after they have been formed, to relieve residual internal stresses introduced during manufacture. Especially for smaller, simpler objects, annealing may be incidental to the process of manufacture, but in larger or more complex products it commonly demands a special process of annealing in a temperature-controlled kiln known as a lehr (glassmaking), lehr.E. F. Collins (1921) Electrically heated glass annealing lehr. Journal of the American Ceramic Society 4 (5), pp. 335–349 Annealing of glass is critical to its durability. Glass that has not been properly annealed retains thermal stresses caused by quenching, which will indefinitely decrease the strength and reliability of the product. Inadequately annealed glass is likely to crack or shatter when subjected to relatively small temperature changes or to mechanical shock or stress. It even may fail spontaneously. To anneal glass, it is necessary to heat it to its annea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxidizing And Reducing Flames

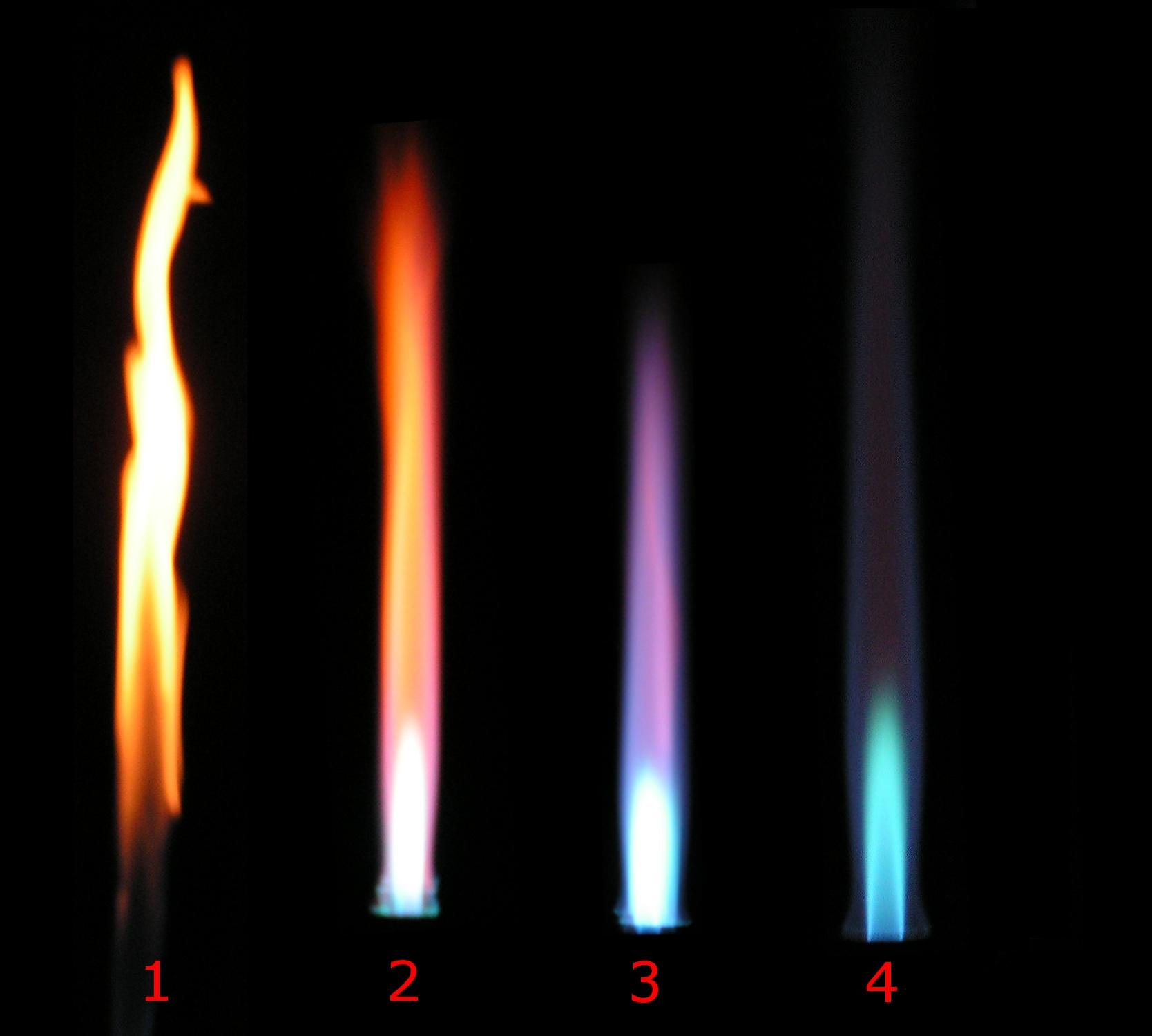

In pyrology, flames are affected by the fuel introduced and the oxygen available. A flame with a good oxygen-fuel ratio is called a neutral flame. The color of the flame is semi-transparent purple or blue. This flame is optimal for all intentions, because it does not oxidize or get soot onto surfaces. Oxidizing flame If the flame has too much oxygen, an oxidizing flame is produced. When the amount of oxygen increases, the flame shortens due to quicker combustion, its color becomes a more transparent blue, and it hisses/roars."The Anatomy of a Flame" in: "Jewelry concepts and technology", by Oppi Untracht, 1983, With some exceptions (e.g., platinum |

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or col ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |