|

Knock-down Fastener

{{sources needed, date=June 2021 Knock-down fasteners are a class of fasteners designed to allow for repeated assembly and disassembly. They are often used in flat pack furniture, which is typified by items such as book cases and wall units that come in a package of pre-cut and pre-drilled components ready to assemble by a novice. Knock-down fasteners can generally be assembled with a single driver, such as a hex key, which may be included in a hardware kit that comes with the product. They self-align when tightened, and allow for a secure connection without requiring drilling or gluing by the consumer. One common type of knock-down fastener is the cam lock, used in butt joint A butt joint is a technique in which two pieces of material are joined by simply placing their ends together without any special shaping. The name "butt joint" comes from the way the material is joined. The butt joint is the simplest joint to ma ...s. After two members are brought together, a cam lock i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fasteners

A fastener (US English) or fastening (UK English) is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Welding is an example of creating permanent joints. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel. Other alternative methods of joining materials include: crimping, welding, soldering, brazing, taping, gluing, cement, or the use of other adhesives. Force may also be used, such as with magnets, vacuum (like suction cups), or even friction (like sticky pads). Some types of woodworking joints make use of separate internal reinforcements, such as dowels or biscuits, which in a sense can be considered fasteners within the scope of the joint system, although on their own they are not general purpose fasteners. Furniture supplied in flat-pack form often uses cam ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Pack Furniture

Ready-to-assemble furniture (RTA), also known as knock-down furniture (KD), flat pack furniture, or kit furniture, is a form of furniture that requires customer assembly. The separate components are packed for sale in cartons which also contain assembly instructions and sometimes hardware. The furniture is generally simple to assemble with basic tools such as screwdrivers, which are also sometimes included. Ready-to-assemble furniture is popular with consumers who wish to save money by assembling the product themselves. Producers and merchants benefit from selling ready-to-assemble furniture because furniture is bulky once assembled, and thus more expensive to store and to deliver. Since the assembly work is done by the consumer instead of by the manufacturer, its price can be lower. A furniture assembly service industry has developed, making it easy for consumers to employ someone knowledgeable to assemble their furniture for them. Produced mainly from chipboard or medium den ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screwdriver

A screwdriver is a tool, manual or powered, used for turning screws. A typical simple screwdriver has a handle and a shaft, ending in a tip the user puts into the screw head before turning the handle. This form of the screwdriver has been replaced in many workplaces and homes with a more modern and versatile tool, a power drill, as they are quicker, easier, and can also drill holes. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handles are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains various t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hex Key

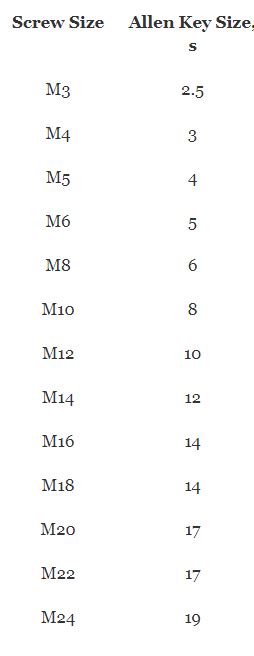

Hex keys of various sizes Socket head screws of various sizes A hex key (also, hex wrench, Allen key and Allen wrench) is a simple driver for bolts or screws that have heads with ''internal'' hexagonal recesses (sockets). Hex keys are formed from a single piece of hard hexagonal steel rod, having blunt ends that fit snugly into similarly-shaped screw sockets. The rods are bent to 90º, forming two arms of unequal length resembling an "L". The tool is usually held and twisted by its long arm, creating a relatively large torque at the tip of the short arm; it can also be held by its short arm to access screws in difficult-to-reach locations and to turn screws faster at the expense of torque. Hex keys are designated with a socket size and are manufactured with tight tolerances. As such, they are commonly sold in kits that include a variety of sizes. Key length typically increases with size, but not necessarily proportionally so. Variants on this design have the short end inse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled. In rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole ( top-hammer drill) or within the hole (down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cross-section; a square cross-section is possible. Process Drilled holes are char ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gluing

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation. The use of adhesives offers certain advantages over other binding techniques such as sewing, mechanical fastenings, or welding. These include the ability to bind different materials together, the more efficient distribution of stress across a joint, the cost-effectiveness of an easily mechanized process, and greater flexibility in design. Disadvantages of adhesive use include decreased stability at high temperatures, relative weakness in bonding large objects with a small bonding surface area, and greater difficulty in separating objects during testing. Adhesives are typically organized by the method of adhesion followed by ''reactive'' or ''non-reactive'', a term which refers to whether the adhesive chemically reacts in order to harden. Alternatively, they can be organized eithe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam Lock (fastener)

A butt joint is a technique in which two pieces of material are joined by simply placing their ends together without any special shaping. The name "butt joint" comes from the way the material is joined. The butt joint is the simplest joint to make since it merely involves cutting the material to the appropriate length and butting them together. It is also the weakest because unless some form of reinforcement is used (see below), it relies upon glue or welding alone to hold it together. Because the orientation of the material usually presents only one end to a long gluing or welding surface, the resulting joint is inherently weak. Nonetheless, it generally provides sufficient strength in most cases, particularly when fasteners are used. The butt joint is widely used in many applications due to its simplicity, notably in rough carpentry and construction. Methods The butt joint is a very simple joint to construct. Members are simply docked (cut off) at the right angle and have a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Butt Joint

A butt joint is a technique in which two pieces of material are joined by simply placing their ends together without any special shaping. The name "butt joint" comes from the way the material is joined. The butt joint is the simplest joint to make since it merely involves cutting the material to the appropriate length and butting them together. It is also the weakest because unless some form of reinforcement is used (see below), it relies upon glue or welding alone to hold it together. Because the orientation of the material usually presents only one end to a long gluing or welding surface, the resulting joint is inherently weak. Nonetheless, it generally provides sufficient strength in most cases, particularly when fasteners are used. The butt joint is widely used in many applications due to its simplicity, notably in rough carpentry and construction. Methods The butt joint is a very simple joint to construct. Members are simply docked (cut off) at the right angle and have a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)