|

Knitting Machine

A knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion. There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles, push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers. Process Early flat bed stocking frames had low carbon steel bearded needles where the tips were reflexed and could be depressed onto a hollow closing the loop. The needles were supported on a ''needle bar'' (''bed)'' that passed back and forth, to and from the operator. The beards were simultaneously depressed by a ''presser bar''. #The needle bar goes forward- the open needles clear the web #The weft thread is laid on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knitting Machine

A knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion. There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles, push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers. Process Early flat bed stocking frames had low carbon steel bearded needles where the tips were reflexed and could be depressed onto a hollow closing the loop. The needles were supported on a ''needle bar'' (''bed)'' that passed back and forth, to and from the operator. The beards were simultaneously depressed by a ''presser bar''. #The needle bar goes forward- the open needles clear the web #The weft thread is laid on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Susanna Lewis

Susanna E. Lewis (1938 – July 15, 2021) was an American fiber artist, teacher and author known for her contributions to the Art to Wear movement. Biography and Work The daughter of an Army Air Forces officer, Lewis received a BA from University of Michigan and an MA from the Teachers College of Columbia University. She later attended the Pratt Institute. Lewis was active in Art to Wear movement in the 1970s and 1980s. Inspired by Mary Walker Phillips she bought a knitting machine (the Passap Duomatic 5) in 1971 and taught herself, beginning to create hangings and garments in the late 1970s. She is known for her highly decorated textile wearable pieces, a direction she was encouraged to take by Julie Schafler Dale, her gallerist. For instance, the ''Moth Cape'' represented a nightmare, "''wherein a feeling of death enveloped her like the wings of a giant moth''". The weight and shape of the piece meant the wearer could share that experience. Lewis was also an author ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

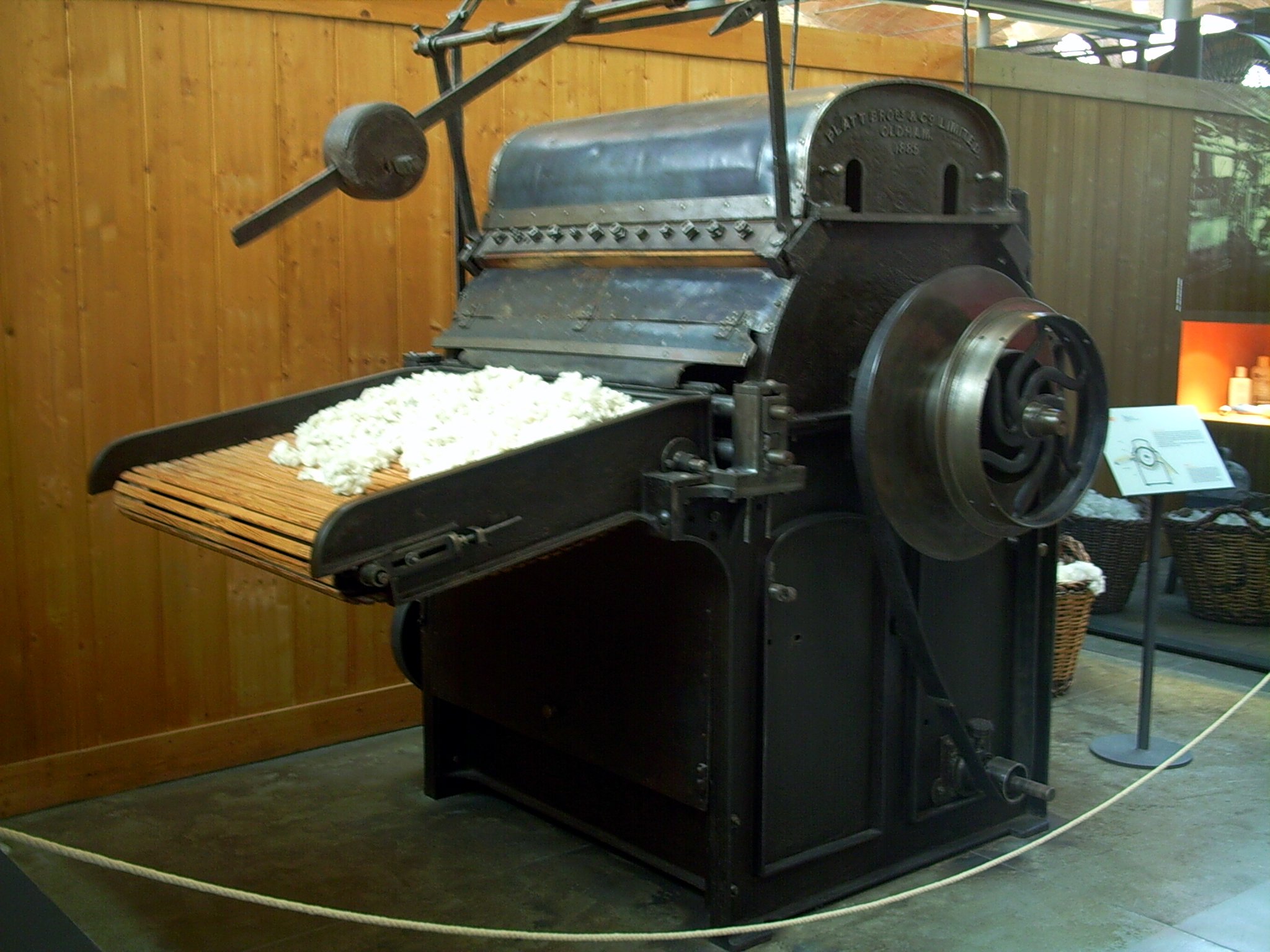

Textile Manufacturing

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household work. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Luddites

The Luddites were a secret oath-based organisation of English textile workers in the 19th century who formed a radical faction which destroyed textile machinery. The group is believed to have taken its name from Ned Ludd, a legendary weaver supposedly from Anstey, near Leicester. They protested against manufacturers who used machines in what they called "a fraudulent and deceitful manner" to get around standard labour practices. Luddites feared that the time spent learning the skills of their craft would go to waste, as machines would replace their role in the industry. Many Luddites were owners of workshops that had closed because factories could sell the same products for less. But when workshop owners set out to find a job at a factory, it was very hard to find one because producing things in factories required fewer workers than producing those same things in a workshop. This left many people unemployed and angry. The Luddite movement began in Nottingham in England and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stocking Frame

A stocking frame was a mechanical knitting machine used in the textiles industry. It was invented by William Lee of Calverton near Nottingham in 1589. Its use, known traditionally as framework knitting, was the first major stage in the mechanisation of the textile industry, and played an important part in the early history of the Industrial Revolution. It was adapted to knit cotton and to do ribbing, and by 1800 had been adapted as a lace making machine. Description Lee's machine consisted of a stout wooden frame. It did straight knitting, not tubular knitting. It had a separate needle for each loop - these were low carbon steel bearded needles where the tips were reflexed and could be depressed onto a hollow, closing the loop. The needles were supported on a needle bar that passed back and forth, to and from the operator. The beards were simultaneously depressed by a presser bar. The first machine had eight needles per inch and was suitable for worsted. The next version had 1 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

History Of Knitting

Knitting is the process of using two or more needles to pull and loop yarn into a series of interconnected loops in order to create a finished garment or some other type of fabric. The word is derived from ''knot'', thought to originate from the Dutch verb ''knutten'', which is similar to the Old English ''cnyttan'', “to knot”. Its origins lie in the basic human need for clothing for protection against the elements. More recently, hand knitting has become less a necessary skill and more of a hobby. Origins of knitting Knitting is a technique of producing fabric from a strand of yarn or wool. Unlike weaving, knitting does not require a loom or other large equipment, making it a valuable technique for nomadic and non-agrarian peoples. The oldest knitted artifacts are socks from Egypt, dating from the 11th century. They are a very fine gauge, done with complex colourwork and some have a short row heel, which necessitates the purl stitch. These complexities suggest that kni ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stockinette

Basic knitted fabrics include stocking stitch, reverse stocking stitch, garter stitch, seed stitch, faggoting, and tricot. In some cases, these fabrics appear differently on the right side (as seen when making the stitch) than on the wrong side (as seen from the other side, when the work is turned). Stockinette/stocking stitch and reverse stockinette stitch Stocking stitch (in US, stockinette stitch) is the most basic knitted fabric; every stitch (as seen from the right side) is a knit stitch. In the round, stocking stitch is produced by knitting every stitch; by contrast, in the flat, stocking stitch is produced by knitting and purling alternate rows. Stocking-stitch fabric is very smooth and each column ("wale") resembles a stacked set of "V"'s. It has a strong tendency to curl horizontally and vertically because of the asymmetry of its faces. Reverse stocking stitch is produced in the same way as stocking, except that the purl stitches are done on the right side and the kn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Knitting

Flat knitting is a method for producing knitted fabrics in which the work is turned periodically; that is, the fabric is worked with alternating sides facing the knitter. Another method of achieving the same result is to knit alternately from right to left and left to right without turning; this back-and-forth technique requires either innate or learned ambidextrous motor skills. The two sides (or "faces") of the fabric are usually designated as the right side (the side that faces outwards, towards the viewer and away from the wearer's body) and the wrong side (the side that faces inwards, away from the viewer and towards the wearer's body). Flat knitting is usually contrasted with circular knitting, in which the fabric is always knitted from the same side. Flat knitting can complicate knitting somewhat compared with circular knitting, since the same stitch (as seen from the right side) is produced by two different movements when knitted from the right and wrong sides. Thus, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knitting Needle

A knitting needle or knitting pin is a tool in hand-knitting to produce knitted fabrics. They generally have a long shaft and taper at their end, but they are not nearly as sharp as sewing needles. Their purpose is two-fold. The long shaft ''holds'' the active (unsecured) stitches of the fabric, to prevent them from unravelling, whereas the tapered ends are used to ''form new stitches''. Most commonly, a new stitch is formed by inserting the tapered end through an active stitch, catching a loop (also called a bight) of fresh yarn and drawing it through the stitch; this secures the initial stitch and forms a new active stitch in its place. In specialized forms of knitting the needle may be passed between active stitches being held on another needle, or indeed between/through inactive stitches that have been knit previously. The size of a needle is described first by its diameter and secondly by its length. The size of the new stitch is determined in large part by the diamete ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Knitting

Hand knitting is a form of knitting, in which the knitted fabric is produced by hand using needles. Types Flat knitting Flat knitting uses two straight needles to make generally two-dimensional (flat) pieces. Flat knitting is usually used to knit flat pieces like scarves, blankets, afghans, and the backs, fronts and arms of sweaters (pullovers). In flat knitting, generally stockinette stitch, the hand-knitter knits from right-to-left on one side of the fabric, turns the work (over), and then purls right-to-left back to the starting position. Usually, the smooth side of the fabric is considered the ''right side'', the one facing outwards for viewing; and the side that faces inwards, towards the body, the ridged side, is known as the ''wrong side''. Thus, flat knitting involves knitting each row on the right side, then purling each row on the wrong side, etc. If each row is knit (no purls) this creates garter stitch, which has the same appearance on both sides and creates ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fair Isle (technique)

Fair Isle (/fɛəraɪ̯l/) is a traditional knitting technique used to create patterns with multiple colours. It is named after Fair Isle, one of the Shetland Islands. Fair Isle knitting gained considerable popularity when the Prince of Wales (later Edward VIII) wore Fair Isle jumpers in public in 1921. Traditional Fair Isle patterns have a limited palette of five or so colours, use only two colours per row, are worked in the round, and limit the length of a run of any particular colour. Some people use the term "Fair Isle" to refer to any colourwork knitting where stitches are knitted alternately in various colours, with the unused colours stranded across the back of the work, but this is inaccurate. The term "stranded colourwork" is applicable for the generic technique, and the term "Fair Isle" is reserved for the characteristic patterns of Shetland. Other techniques for knitting in colour include intarsia, slip-stitch colour (also known as mosaic knitting A mosaic is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |