|

Ignition Timing

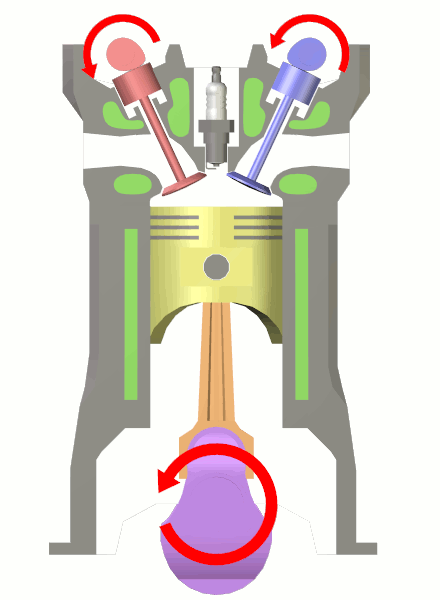

In a spark ignition internal combustion engine, ignition timing is the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke. The need for advancing (or retarding) the timing of the spark is because fuel does not completely burn the instant the spark fires. The combustion gases take a period of time to expand and the angular or rotational speed of the engine can lengthen or shorten the time frame in which the burning and expansion should occur. In a vast majority of cases, the angle will be described as a certain angle advanced ''before top dead center'' (BTDC). Advancing the spark BTDC means that the spark is energized prior to the point where the combustion chamber reaches its minimum size, since the purpose of the power stroke in the engine is to force the combustion chamber to expand. Sparks occurring after top dead center (ATDC) are usually counter-productive (prod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Patern In Dependence On Ignition Timing

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and even by industry. Further, both spellings are often used ''within'' a particular industry or country. Industries in British English-speaking countries typically use the "gauge" spelling. is the pressure relative to the ambient pressure. Various units are used to express pressure. Some of these derive from a unit of force divided by a unit of area; the SI unit of pressure, the pascal (Pa), for example, is one newton per square metre (N/m2); similarly, the pound-force per square inch ( psi) is the traditional unit of pressure in the imperial and U.S. customary systems. Pressure may also be expressed in terms of standard atmospheric pressure; the atmosphere (atm) is equal to this pressure, and the torr is defined as of this. Manometric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distributor

A distributor is an enclosed rotating switch used in spark-ignition internal combustion engines that have mechanically timed ignition. The distributor's main function is to route high voltage current from the ignition coil to the spark plugs in the correct firing order, and for the correct amount of time. Except in magneto systems and many modern computer controlled engines that use crank angle/position sensors, the distributor also houses a mechanical or inductive breaker switch to open and close the ignition coil's primary circuit. The first reliable battery operated ignition was the Delco ignition system developed by Dayton Engineering Laboratories Co. (Delco) and introduced in the 1910 Cadillac Model 30. This ignition was developed by Charles Kettering and was considered a wonder in its day. Atwater Kent invented his Unisparker ignition system about this time in competition with the Delco system. By the end of the 20th century mechanical ignitions were disappea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Top Dead Centre

In a reciprocating engine, the dead centre is the position of a piston in which it is either farthest from, or nearest to, the crankshaft. The former is known as Top Dead Centre (TDC) while the latter is known as Bottom Dead Centre (BDC). More generally, the dead centre is any position of a crank where the applied force is straight along its axis, meaning no turning force can be applied. Many sorts of machines are crank driven, including unicycles, bicycles, tricycles, various types of machine presses, gasoline engines, diesel engines, steam locomotives, and other steam engines. Crank-driven machines rely on the energy stored in a flywheel to overcome the dead centre, or are designed, in the case of multi-cylinder engines, so that dead centres can never exist on all cranks at the same time. A steam locomotive is an example of the latter, the connecting rods being arranged such that the dead centre for each cylinder occurs out of phase with the other one (or more) cylind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process. Design The crankshaft located within the engine block, held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormous stresses, in some cases more than per cylinder. Crankshafts for single- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Timing Mark

A timing mark is an indicator used for setting the timing of the ignition system of an engine, typically found on the crankshaft pulley (as pictured) or the flywheel, being the largest radius rotating at crankshaft speed and therefore the place where marks at one degree intervals will be farthest apart. On older engines it is common to set the ignition timing using a timing light, which flashes in time with the ignition system (and hence engine rotation), so when shone on the timing marks makes them appear stationary due to the stroboscopic effect. The ignition timing can then be adjusted to fire at the correct point in the engine's rotation, typically a few degrees before top dead centre and advancing with increasing engine speed. The timing can be adjusted by loosening and slightly rotating the distributor A distributor is an enclosed rotating switch used in spark-ignition internal combustion engines that have mechanically timed ignition. The distributor's main fun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger,[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and even by industry. Further, both spellings are often used ''within'' a particular industry or country. Industries in British English-speaking countries typically use the "gauge" spelling. is the pressure relative to the ambient pressure. Various units are used to express pressure. Some of these derive from a unit of force divided by a unit of area; the SI unit of pressure, the pascal (Pa), for example, is one newton per square metre (N/m2); similarly, the pound-force per square inch ( psi) is the traditional unit of pressure in the imperial and U.S. customary systems. Pressure may also be expressed in terms of standard atmospheric pressure; the atmosphere (atm) is equal to this pressure, and the torr is defined as of this. Manome ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Temperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measured with a thermometer. Thermometers are calibrated in various temperature scales that historically have relied on various reference points and thermometric substances for definition. The most common scales are the Celsius scale with the unit symbol °C (formerly called ''centigrade''), the Fahrenheit scale (°F), and the Kelvin scale (K), the latter being used predominantly for scientific purposes. The kelvin is one of the seven base units in the International System of Units (SI). Absolute zero, i.e., zero kelvin or −273.15 °C, is the lowest point in the thermodynamic temperature scale. Experimentally, it can be approached very closely but not actually reached, as recognized in the third law of thermodynamics. It would be impossible to extract energy as heat from a body at that temperature. Temperature is important in all fields of na ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air mixture by an electric spark, while containing combustion pressure within the engine. A spark plug has a metal threaded shell, electrically isolated from a central electrode by a ceramic insulator. The central electrode, which may contain a resistor, is connected by a heavily insulated wire to the output terminal of an ignition coil or magneto. The spark plug's metal shell is screwed into the engine's cylinder head and thus electrically grounded. The central electrode protrudes through the porcelain insulator into the combustion chamber, forming one or more spark gaps between the inner end of the central electrode and usually one or more protuberances or structures attached to the inner end of the threaded shell and designated the ''s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injector

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburettors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburettor relies on suction created by intak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intake Valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine. It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usually a disk shape on the end of a shaft known as a valve stem. The working end of this plug, the valve face, is typically ground at a 45° bevel to seal against a corresponding valve seat ground into the rim of the chamber being sealed. The shaft travels through a valve guide to maintain its alignment. A pressure differential on either side of the valve can assist or impair its performance. In exhaust applications higher pressure against the valve helps to seal it, and in intake applications lower pressure helps open it. The poppet valve was invented in 1833 by American E.A.G. Young of the New Castle and Frenchtown Turnpike and Railroad Company, Newcastle and Frenchtown Railroad. Young had patented his idea, but the 1836 U.S. Patent Offic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Timing

In a piston engine, the valve timing is the precise timing of the opening and closing of the valves. In an internal combustion engine those are usually poppet valves and in a steam engine they are usually slide valves or piston valves. Internal combustion engines Camshaft In four-stroke cycle engines and some two-stroke cycle engines, the valve timing is controlled by the camshaft. It can be varied by modifying the camshaft, or it can be varied during engine operation by variable valve timing. It is also affected by the adjustment of the valve mechanism, and particularly by the tappet clearance. However, this variation is normally unwanted. Valve overlap With traditional fixed valve timing, an engine will have a period of "valve overlap" at the end of the exhaust stroke, when both the intake and exhaust valves are open. The intake valve is opened before the exhaust gases have completely left the cylinder, and their considerable velocity assists in drawing in the fresh ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |