|

Hypoid

A spiral bevel gear is a bevel gear with helical teeth. The main application of this is in a vehicle differential, where the direction of drive from the drive shaft must be turned 90 degrees to drive the wheels. The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth. A spiral bevel gear set should always be replaced in pairs i.e. both the left hand and right hand gears should be replaced together since the gears are manufactured and lapped in pairs. Handedness A right hand spiral bevel gear is one in which the outer half of a tooth is inclined in the clockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. A left hand spiral bevel gear is one in which the outer half of a tooth is inclined in the counterclockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. No ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hypoid

A spiral bevel gear is a bevel gear with helical teeth. The main application of this is in a vehicle differential, where the direction of drive from the drive shaft must be turned 90 degrees to drive the wheels. The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth. A spiral bevel gear set should always be replaced in pairs i.e. both the left hand and right hand gears should be replaced together since the gears are manufactured and lapped in pairs. Handedness A right hand spiral bevel gear is one in which the outer half of a tooth is inclined in the clockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. A left hand spiral bevel gear is one in which the outer half of a tooth is inclined in the counterclockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. No ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spiral Angle

A spiral bevel gear is a bevel gear with helical teeth. The main application of this is in a vehicle differential, where the direction of drive from the drive shaft must be turned 90 degrees to drive the wheels. The helical design produces less vibration and noise than conventional straight-cut or spur-cut gear with straight teeth. A spiral bevel gear set should always be replaced in pairs i.e. both the left hand and right hand gears should be replaced together since the gears are manufactured and lapped in pairs. Handedness A right hand spiral bevel gear is one in which the outer half of a tooth is inclined in the clockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. A left hand spiral bevel gear is one in which the outer half of a tooth is inclined in the counterclockwise direction from the axial plane through the midpoint of the tooth as viewed by an observer looking at the face of the gear. No ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Helical Gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a '' transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Worm Gear

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm gear. The terminology is often confused by imprecise use of the term ''worm gear'' to refer to the worm, the worm wheel, or the worm drive as a unit. The worm drive or "endless screw" was invented by either Archytas of Terentum, Apollonius of Perga, or Archimedes, the last one being the most probable author.Witold Rybczynski, '' One good turn : a natural history of the screwdriver and the screw''. London, 2000. Page 139. The worm drive later appeared in the Indian subcontinent, for use in roller cotton gins, during the Delhi Sultanate in the thirteenth or fourteenth centuries.Irfan Habib''Economic History of Medieval India, 1200–1500'', page 53 Pearson Education Explanation A gearbox designed using a worm and worm wheel is considerably smaller than on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Differential (mechanical Device)

A differential is a gear train with three drive shafts that has the property that the rotational speed of one shaft is the average of the speeds of the others, or a fixed multiple of that average. Functional description The following description of a differential applies to a traditional rear-wheel-drive car or truck with an open or limited slip differential combined with a reduction gearset using bevel gears (these are not strictly necessary; see spur-gear differential): Thus, for example, if the car is making a turn to the right, the main ring gear may make 10 full rotations. During that time, the left wheel will make more rotations because it has farther to travel, and the right wheel will make fewer rotations as it has less distance to travel. The sun gears (which drive the axle half-shafts) will rotate at different speeds relative to the ring gear (one faster, one slower) by, say, 2 full turns each (4 full turns relative to each other), resulting in the left wheel mak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Worm Drive

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm gear. The terminology is often confused by imprecise use of the term ''worm gear'' to refer to the worm, the worm wheel, or the worm drive as a unit. The worm drive or "endless screw" was invented by either Archytas of Terentum, Apollonius of Perga, or Archimedes, the last one being the most probable author.Witold Rybczynski, '' One good turn : a natural history of the screwdriver and the screw''. London, 2000. Page 139. The worm drive later appeared in the Indian subcontinent, for use in roller cotton gins, during the Delhi Sultanate in the thirteenth or fourteenth centuries.Irfan Habib''Economic History of Medieval India, 1200–1500'', page 53 Pearson Education Explanation A gearbox designed using a worm and worm wheel is considerably smaller than on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bevel Gear

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone, known as a pitch cone. Bevel gears transfer the energy from linear to vertical power, making it very useful in machines widely used in mechanical settings. Introduction Two important concepts in gearing are pitch surface and pitch angle. The pitch surface of a gear is the imaginary toothless surface that you would have by averaging out the peaks and valleys of the individual teeth. The pitch surface of an ordinary gear is the shape of a cylinder. The pitch angle of a gear is the angle between the face of the pitch surface and the axis. The most familiar kinds of bevel gears have pitch angles of less than 90 degrees and therefore are cone-shaped. This type of bevel gear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bevel Gear

Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. Bevel gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone, known as a pitch cone. Bevel gears transfer the energy from linear to vertical power, making it very useful in machines widely used in mechanical settings. Introduction Two important concepts in gearing are pitch surface and pitch angle. The pitch surface of a gear is the imaginary toothless surface that you would have by averaging out the peaks and valleys of the individual teeth. The pitch surface of an ordinary gear is the shape of a cylinder. The pitch angle of a gear is the angle between the face of the pitch surface and the axis. The most familiar kinds of bevel gears have pitch angles of less than 90 degrees and therefore are cone-shaped. This type of bevel gear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Gear Nomenclature

This page lists the standard US nomenclature used in the description of mechanical gear construction and function, together with definitions of the terms. The terminology was established by the American Gear Manufacturers Association (AGMA), under accreditation from the American National Standards Institute (ANSI). Addendum The addendum is the height by which a tooth of a gear projects beyond (outside for external, or inside for internal) the standard pitch circle or pitch line; also, the radial distance between the pitch diameter and the outside diameter. Addendum angle Addendum angle in a bevel gear, is the angle between face cone and pitch cone. Addendum circle The addendum circle coincides with the tops of the teeth of a gear and is concentric with the standard (reference) pitch circle and radially distant from it by the amount of the addendum. For external gears, the addendum circle lies on the outside cylinder while on internal gears the addendum circle lies on th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

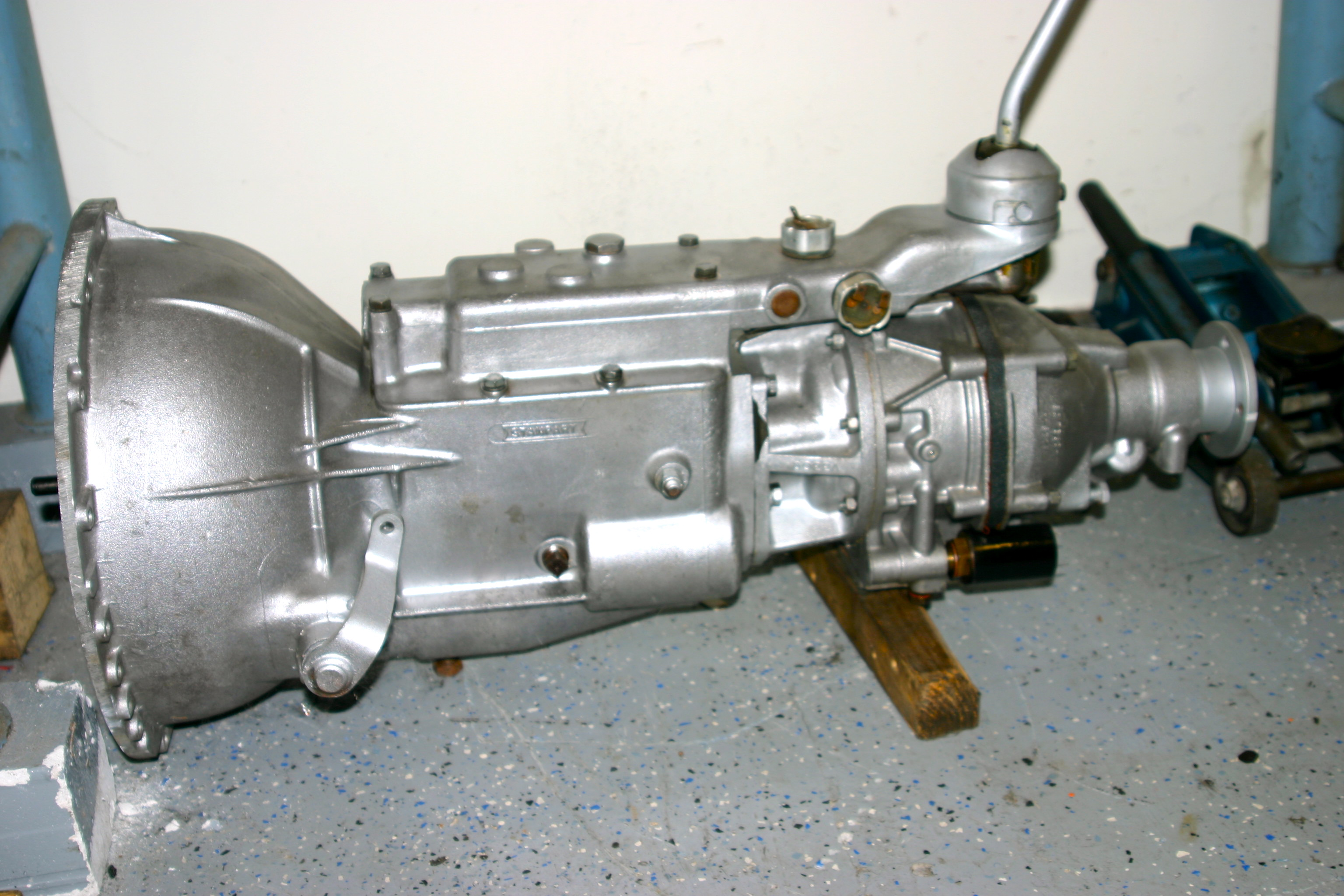

Gear Housing

The gear housing is a mechanical housing that surrounds the mechanical components of a gear box. It provides mechanical support for the moving components, a mechanical protection from the outside world for those internal components, and a fluid-tight container to hold the lubricant that bathes those components. Types of housings A split housing is like a walnut shell, the housing is divided in two parts, and lower part that tie down the Gear Box to the structure, support all the components during the assembly stage and hold the lubrication oil; and the upper part that complete the enclosure and provide mechanical integrity to the Housing. The upper and lower parts of the housing have a mating surface that seals perfectly the housing to avoid oil leaks and fatigue of the housing. A bathtub housing is made on a single piece and have a top opening for servicing the gear box and side opening to accommodate the bearing housing associated to the gear shafts. Have in general a better le ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Economy In Automobiles

The fuel economy of an automobile relates distance traveled by a vehicle and the amount of fuel consumed. Consumption can be expressed in terms of volume of fuel to travel a distance, or the distance traveled per unit volume of fuel consumed. Since fuel consumption of vehicles is a significant factor in air pollution, and since importation of motor fuel can be a large part of a nation's foreign trade, many countries impose requirements for fuel economy. Different methods are used to approximate the actual performance of the vehicle. The energy in fuel is required to overcome various losses (wind resistance, tire drag, and others) encountered while propelling the vehicle, and in providing power to vehicle systems such as ignition or air conditioning. Various strategies can be employed to reduce losses at each of the conversions between the chemical energy in the fuel and the kinetic energy of the vehicle. Driver behavior can affect fuel economy; maneuvers such as sudden accelerat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Powertrain

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components. In contrast, the powertrain is considered to include both the engine and/or motor(s) as well as the drivetrain. Function The function of the drivetrain is to couple the engine that produces the power to the driving wheels that use this mechanical power to rotate the axle. This connection involves physically linking the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |