|

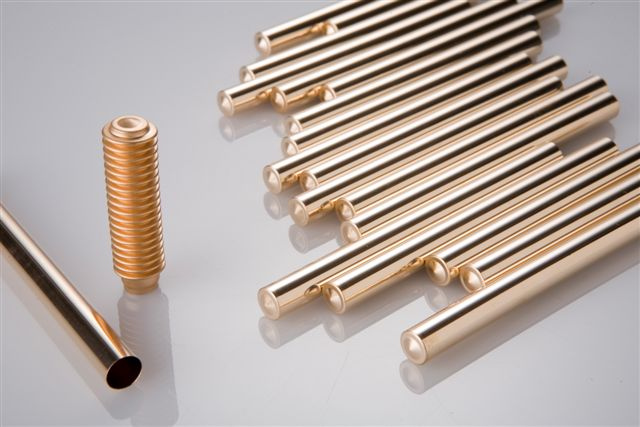

Hydroform

Hydroforming is a cost-effective way of shaping ductile metals such as aluminium, brass, low alloy steel, and stainless steel into lightweight, structurally stiff and strong pieces. One of the largest applications of hydroforming is the automotive industry, which makes use of the complex shapes made possible by hydroforming to produce stronger, lighter, and more rigid unibody structures for vehicles. This technique is particularly popular with the high-end sports car industry and is also frequently employed in the shaping of aluminium tubes for bicycle frames. Hydroforming is a specialized type of die forming that uses a high pressure hydraulic fluid to press room temperature working material into a die. To hydroform aluminium into a vehicle's frame rail, a hollow tube of aluminium is placed inside a negative mold that has the shape of the desired result. High pressure hydraulic pumps then inject fluid at very high pressure inside the aluminium tube which causes it to expand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rubber Pad Forming

Rubber pad forming (RPF) is a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane. Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part. The rubber pads can have a general purpose shape, like a membrane. Alternatively, they can be machined in the shape of die or punch. Rubber pad forming is a deep drawing technique that is ideally suited for the production of small and medium-sized series. Deep drawing makes it possible to deform sheet metal in two directions, which offers great benefits in terms of function integration, weight reduction, cleanability and such. The disadvantage of regular deep drawing is that expensive tools consisting of an upper and lower mold are needed. Once these tools have been made, the variable costs are low, which makes regular deep drawing very suitable for large and very large numbers of products. Technique In the rubber pad forming process on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a press. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrohydraulic Forming

Electrohydraulic forming is a type of :Metal forming, metal forming in which an electric arc discharge in liquid is used to convert electrical energy to mechanical energy and change the shape of the workpiece. A capacitor bank delivers a pulse of high current across two electrodes, which are positioned a short distance apart while submerged in a fluid (water or oil). The electric arc discharge rapidly vaporizes the surrounding fluid, creating a shock wave. The workpiece, which is kept in contact with the fluid, is deformed into an evacuated die (manufacturing), die. The potential forming capabilities of submerged arc discharge processes were recognized as early as the mid-1940s (Yutkin L.A.). During the 1950s and early 1960s, the basic process was developed into production systems. This work principally was by and for the aerospace industries. By 1970, forming machines based on submerged arc discharge were available from machine tool builders. A few of the larger aerospace fabricat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Allen Telescope Array

The Allen Telescope Array (ATA), formerly known as the One Hectare Telescope (1hT), is a radio telescope array dedicated to astronomical observations and a simultaneous search for extraterrestrial intelligence (SETI). The array is situated at the Hat Creek Radio Observatory in Shasta County, northeast of San Francisco, California. The project was originally developed as a joint effort between the SETI Institute and the Radio Astronomy Laboratory (RAL) at the University of California, Berkeley (UC Berkeley), with funds obtained from an initial 12.5 million donation by the Paul G. Allen Family Foundation and Nathan Myhrvold. The first phase of construction was completed and the ATA finally became operational on 11 October 2007 with 42 antennas (ATA-42), after Paul Allen (co-founder of Microsoft) had pledged an additional $13.5 million to support the construction of the first and second phases. Although overall Allen has contributed more than $30 million to the project, it has no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deep Drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius. Deep drawing presses, especially in the Aerospace and Medical industries, require unparalleled accuracy and precision. Sheet hydroforming presses do complex draw work. Bed size, tonnage, stroke, speed, and more ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

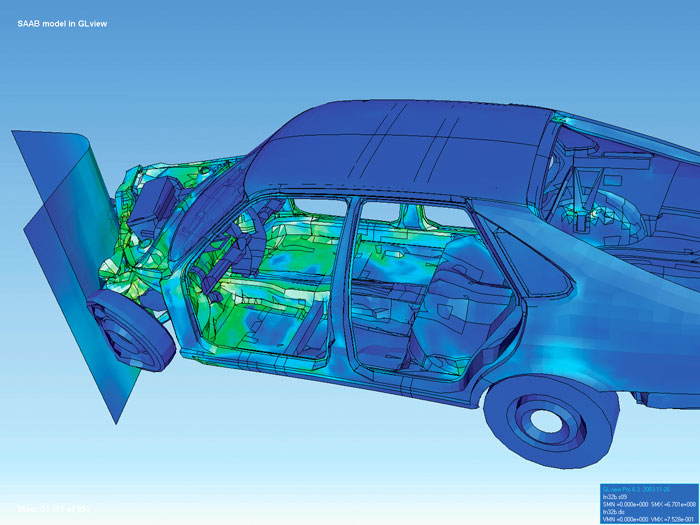

Finite Elements

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The sim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Explosive Forming

Explosive forming is a metalworking technique in which an explosive charge is used instead of a punch or press. It can be used on materials for which a press setup would be prohibitively large or require an unreasonably high pressure, and is generally much cheaper than building a large enough and sufficiently high-pressure press; on the other hand, it is unavoidably an individual job production process, producing one product at a time and with a long setup time. There are various approaches; one is to place metal plate over a die, with the intervening space evacuated by a vacuum pump, place the whole assembly underwater, and detonate a charge at an appropriate distance from the plate. For complicated shapes, a segmented die can be used to produce in a single operation a shape that would require many manufacturing steps, or to be manufactured in parts and welded together with an accompanying loss of strength at the welds. There is often some degree of work hardening from the explos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inertia

Inertia is the idea that an object will continue its current motion until some force causes its speed or direction to change. The term is properly understood as shorthand for "the principle of inertia" as described by Newton in his first law of motion. After some other definitions, Newton states in his first law of motion: The word "perseveres" is a direct translation from Newton's Latin. Other, less forceful terms such as "to continue" or "to remain" are commonly found in modern textbooks. The modern use follows from some changes in Newton's original mechanics (as stated in the ''Principia'') made by Euler, d'Alembert, and other Cartesians. The term inertia comes from the Latin word ''iners'', meaning idle, sluggish. The term inertia may also refer to the resistance of any physical object to a change in its velocity. This includes changes to the object's speed or direction of motion. An aspect of this property is the tendency of objects to keep moving in a straight li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Early THF Application

{{disambiguation, geo ...

Early may refer to: History * The beginning or oldest part of a defined historical period, as opposed to middle or late periods, e.g.: ** Early Christianity ** Early modern Europe Places in the United States * Early, Iowa * Early, Texas * Early Branch, a stream in Missouri * Early County, Georgia Other uses * ''Early'' (Scritti Politti album), 2005 * ''Early'' (A Certain Ratio album), 2002 * Early (name) * Early effect, an effect in transistor physics * Early Records, a record label * the early part of the morning See also * Earley (other) Earley is a town in England. Earley may also refer to: * Earley (surname), a list of people with the surname Earley * Earley (given name), a variant of the given name Earlene * Earley Lake, a lake in Minnesota *Earley parser, an algorithm *Earley ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tube Hydroforming Process Sequence

Tube or tubes may refer to: * ''Tube'' (2003 film), a 2003 Korean film * ''The Tube'' (TV series), a music related TV series by Channel 4 in the United Kingdom * "Tubes" (Peter Dale), performer on the Soccer AM television show * Tube (band), a Japanese rock band * Tube & Berger, the alias of dance/electronica producers Arndt Rörig and Marco Vidovic from Germany * The Tube Music Network, a music video network that operated between 2006 and 2007 * The Tubes, a San Francisco-based band, popular in the 1970s and 1980s Other media * Tube, a freeware game for MS-DOS computers from Bullfrog Productions * ''TUBE.'', an online magazine about visual and performing arts, founded in 2012 in Sacramento, California * Series of tubes, an analogy for the Internet used by United States Senator Ted Stevens * Picture tube, term in Paint Shop Pro software for a small digital image with no background * YouTube, a video sharing website Science, technology, and mathematics Construction and mechanic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Punch (metalworking)

A punch is a tool used to indent or create a hole through a hard surface. They usually consist of a hard metal rod with a narrow tip at one end and a broad flat "butt" at the other. When used, the narrower end is pointed against a target surface and the broad end is then struck with a hammer or mallet, causing the blunt force of the blow to be transmitted down the rod body and focused more sharply onto a small area. Typically, woodworkers use a ball-peen hammer to strike a punch. Use Punches are used to drive fasteners such as nails and dowels, making a hole, or forming an indentation/impression of the tip on a workpiece. Decorative punches may also be used to create a pattern or even form an image. Pin Metal pins and similar connectors are driven in or out of holes using a pin punch. For removal, first use a starter punch to loosen the pin, then use a pin punch to finish. Center A ''center punch'' is used to mark the center of a point. It is usually used to mark ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |