|

Heatsink

A heat sink (also commonly spelled heatsink) is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature. In computers, heat sinks are used to cool CPUs, GPUs, and some chipsets and RAM modules. Heat sinks are used with high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light-emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature. A heat sink is designed to maximize its surface area in contact with the cooling medium surrounding it, such as the air. Air velocity, choice of material, protrusion design and surface treatment are factors that affect the performance of a heat sink. Heat sink attachment methods and thermal interface materials also affect the die temperature of t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer Cooling

Computer cooling is required to remove the waste heat produced by computer components, to keep components within permissible operating temperature limits. Components that are susceptible to temporary malfunction or permanent failure if overheated include integrated circuits such as central processing units (CPUs), chipsets, Video card, graphics cards, and hard disk drives. Components are often designed to generate as little heat as possible, and computers and operating systems may be designed to reduce power consumption and consequent heating according to workload, but more heat may still be produced than can be removed without attention to cooling. Use of Heat sink#Microprocessor cooling, heatsinks cooled by airflow reduces the temperature rise produced by a given amount of heat. Attention to patterns of airflow can prevent the development of hotspots. Computer fans are widely used along with heatsink fans to reduce temperature by actively exhausting hot air. There are also mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Management (electronics)

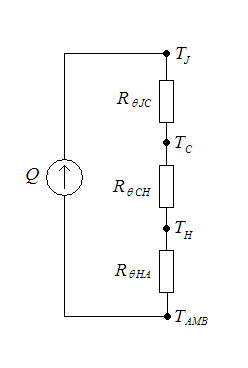

All electronic devices and circuitry generate excess heat and thus require thermal management to improve reliability and prevent premature failure. The amount of heat output is equal to the power input, if there are no other energy interactions. There are several techniques for cooling including various styles of heat sinks, thermoelectric coolers, forced air systems and fans, heat pipes, and others. In cases of extreme low environmental temperatures, it may actually be necessary to heat the electronic components to achieve satisfactory operation. Overview Thermal resistance of devices This is usually quoted as the thermal resistance from junction to case of the semiconductor device. The units are °C/W. For example, a heatsink rated at 10 °C/W will get 10 °C hotter than the surrounding air when it dissipates 1 Watt of heat. Thus, a heatsink with a low °C/W value is more efficient than a heatsink with a high °C/W value. Given two semiconductor device ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

2N3055

The 2N3055 is a silicon NPN power transistor intended for general purpose applications. It was introduced in the early 1960s by RCA using a hometaxial power transistor process, transitioned to an epitaxial base in the mid-1970s. Its numbering follows the JEDEC standard. It is a transistor type of enduring popularity. Specifications The exact performance characteristics depend on the manufacturer and date; before the move to the epitaxial base version in the mid-1970s the fT could be as low as 0.8 MHz, for example. Packaged in a TO-3 case style, it is a 15 amp, 60 volt (or more, see below), 115 watt power transistor with a β (forward current gain) of 20 to 70 at a collector current of 4 A (this may be over 100 when testing at lower currents). It often has a transition frequency of around 3.0 MHz and 6 MHz is typical for the 2N3055A; at this frequency the calculated current gain (beta) drops to 1, indicating the transistor can no longer provide useful ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Resistance

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow. Thermal resistance is the reciprocal of thermal conductance. * (Absolute) thermal resistance ''R'' in kelvins per watt (K/W) is a property of a particular component. For example, a characteristic of a heat sink. * Specific thermal resistance or thermal resistivity ''Rλ'' in kelvin–metres per watt (K⋅m/W), is a material constant. * Thermal insulance has the units square metre kelvin per watt (m2⋅K/W) in SI units or square foot degree Fahrenheit– hours per British thermal unit (ft2⋅°F⋅h/Btu) in imperial units. It is the thermal resistance of unit area of a material. In terms of insulation, it is measured by the R-value. Absolute thermal resistance Absolute thermal resistance is the temperature difference across a structure when a unit of heat energy flows through it in unit time. It is the reciprocal of thermal conductance. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

AMD Heatsink And Fan

Advanced Micro Devices, Inc. (AMD) is an American multinational company, multinational semiconductor industry, semiconductor company based in Santa Clara, California, that develops computer processors and related technologies for business and consumer markets. While it initially manufactured its own processors, the company later outsourced its manufacturing, a practice known as going Fabless manufacturing, fabless, after GlobalFoundries was spun off in 2009. AMD's main products include microprocessors, motherboard chipsets, embedded processors, Graphics processing unit, graphics processors, and FPGAs for server (computing), servers, workstations, personal computers, and embedded system applications. History First twelve years Advanced Micro Devices was formally incorporated by Jerry Sanders (businessman), Jerry Sanders, along with seven of his colleagues from Fairchild Semiconductor, on May 1, 1969. Sanders, an electrical engineer who was the director of marketing at Fai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Transistor Heat Sinks

Power most often refers to: * Power (physics), meaning "rate of doing work" ** Engine power, the power put out by an engine ** Electric power * Power (social and political), the ability to influence people or events ** Abusive power Power may also refer to: Mathematics, science and technology Computing * IBM POWER (software), an IBM operating system enhancement package * IBM POWER architecture, a RISC instruction set architecture * Power ISA, a RISC instruction set architecture derived from PowerPC * IBM Power microprocessors, made by IBM, which implement those RISC architectures * Power.org, a predecessor to the OpenPOWER Foundation * SGI POWER Challenge, a line of SGI supercomputers Mathematics * Exponentiation, "''x'' to the power of ''y''" * Power function * Power of a point * Statistical power Physics * Magnification, the factor by which an optical system enlarges an image * Optical power, the degree to which a lens converges or diverges light Social sciences and politi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Skiving (metalworking)

Skiving or scarfing is the process of cutting material off in slices, usually metal, but also leather or laminates. Skiving is used instead of rolling the material to shape when the material must not be work hardened, or must not shed minute slivers of metal later which is common in cold rolling processes. In metalworking, skiving can be used to remove a thin dimension of material or to create thin slices in an existing material, such as heat sinks where a large amount of surface area is required relative to the volume of the piece of metal. The process involves moving the strip past precision-profiled slotted tools made to an exact shape, or past plain cutting tools. The tools are usually made of tungsten carbide-based compounds. In early machines, it was necessary to precisely position the strip relative to the cutting tools, but newer machines use a floating suspension technology which enables tools to locate by material contact. This allows mutual initial positioning differe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various ''time setting'' materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods. Heavy equipment like machine tool beds, ships' propellers, etc. can be cast easily in the required size, rather than fabricating by joining several small pieces. Casting is a 7,000-year-old process. The oldest surviving casting is a copper frog from 3200 BC. History Throughout history, metal casting has been used to make tools, weapons, and religious objects. Metal casting history and de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal bars and tubes are also often drawn. Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). It can be done with hot or cold material. Commonly extruded materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempering (metallurgy)

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the brittleness of the metal. Tempering is usually performed after quench ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

6063 Aluminium Alloy

AA 6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. The standard controlling its composition is maintained by The Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminium alloy HE9. 6063 is the most common alloy used for aluminium extrusion. It allows complex shapes to be formed with very smooth surfaces fit for anodizing and so is popular for visible architectural applications such as window frames, door frames, roofs, and sign frames. Applications requiring higher strength typically use 6061 or 6082 instead. Chemical composition The alloy composition of 6063 is: Mechanical properties The mechanical properties of 6063 depend greatly on the temper, or heat treatment, of the material. 6063-O Un-heat-treated 6063 has maximum tensile strength no more than , and no specified maximum yield strength. The material has elongation (stretch before ultimate failure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

6061 Aluminium Alloy

6061 ( Unified Numbering System (UNS) designation A96061) is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063). It is one of the most common alloys of aluminium for general-purpose use. It is commonly available in pre-tempered grades such as 6061-O (annealed), tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651 (solutionized, stress-relieved stretched and artificially aged). Chemical composition 6061 Aluminium alloy composition by mass: Properties The mechanical properties of 6061 depend greatly on the temper, or heat treatment, of the material. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |