|

Gear Pump

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic machinery, hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler. Gear pumps are also widely used in chemical installations to pump high viscosity fluids. There are two main variations: ''external gear pumps'' which use two external spur gears, and ''internal gear pumps'' which use an external and an internal spur gear (internal spur gear teeth face inwards, see below). Gear pumps are positive displacement pump, ''positive displacement'' (or ''fixed displacement''), meaning they pump a constant amount of fluid for each revolution. Some gear pumps are designed to function as either a Hydraulic motor, motor or a pump. Theory of operation As the gears rotate they separate on the intake side of the pump, creating a void and suction which is filled by fluid. The fluid is carried by the gears to the discharge sid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Pump Exploded

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a ''transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Motor

A hydraulic motor is a mechanical actuator that converts hydraulics, hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower (namely, water engine, water engines and water motors) but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery. Conceptually, a hydraulic motor should be interchangeable parts, interchangeable with a hydraulic pump because it performs the opposite function - similar to the way a DC electric motor is theoretically interchangeable with a DC electrical generator. However, many hydraulic pumps cannot be used as hydraulic motors because they cannot be backdriven. Also, a hydraulic motor is usually designed for working pre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Pump

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy ( hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. Hydrostatic pumps are positive displacement pumps while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or variable displacement pumps, which have a more complicated construction that allows the displacement to be adjusted. Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons ( piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle ( jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gerotor

A gerotor is a positive displacement pump. The name ''gerotor'' is derived from "generated rotor". A gerotor unit consists of an inner and outer rotor. The inner rotor has ''n'' teeth, while the outer rotor has ''n''+1 teeth; with ''n'' defined as a natural number greater than or equal to 2. The axis of the inner rotor is offset from the axis of the outer rotor and both rotors rotate on their respective axes. The geometry of the two rotors partitions the volume between them into ''n'' different dynamically-changing volumes. During the assembly's rotation cycle, each of these volumes changes continuously, so any given volume first increases, and then decreases. An increase creates a vacuum. This vacuum creates suction, and hence, this part of the cycle is where the inlet is located. As a volume decreases compression occurs. During this compression period, fluids can be pumped, or, if they are gaseous fluids, compressed. Gerotor pumps are generally designed using a trochoidal inner ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superchargers

In an internal combustion engine, a supercharger compresses the intake gas, forcing more air into the engine in order to produce more power for a given displacement. The current categorisation is that a supercharger is a form of forced induction that is mechanically powered (usually by a belt from the engine's crankshaft), as opposed to a turbocharger, which is powered by the kinetic energy of the exhaust gasses. However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. The first supercharged engine was built in 1878, with usage in aircraft engines beginning in the 1910s and usage in car engines beginning in the 1920s. In piston engines used by aircraft, supercharging was often used to compensate for the lower air density at high altitudes. Supercharging is less commonly used in the 21st century, as manufacturers have shifted to turbochargers to reduce fuel consumption and/or increase power outputs. Des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roots Type Supercharger

The Roots-type blower is a positive displacement lobe pump which operates by pumping a fluid with a pair of meshing lobes resembling a set of stretched gears. Fluid is trapped in pockets surrounding the lobes and carried from the intake side to the exhaust. The most common application of the Roots-type blower has been the induction device on two-stroke diesel engines, such as those produced by Detroit Diesel and Electro-Motive Diesel. Roots-type blowers are also used to supercharge four-stroke Otto cycle engines, with the blower being driven from the engine's crankshaft via a toothed or V-belt, a roller chain or a gear train. The Roots-type blower is named after American inventors and brothers Philander and Francis Marion Roots, founders of the Roots Blower Company of Connersville, Indiana USA, who patented the basic design in 1860 as an air pump for use in blast furnaces and other industrial applications. In 1900, Gottlieb Daimler included a Roots-style blower in a pat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

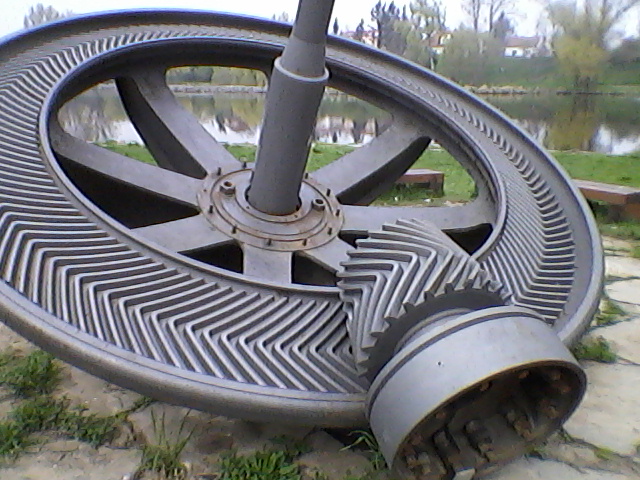

Herringbone Gear

A herringbone gear, a specific type of double helical gear, is a special type of gear that is a side-to-side (not face-to-face) combination of two Gear#Helical, helical gears of opposite Helix#Handedness, hands. From the top, each helical Groove (engineering), groove of this gear looks like the letter V, and many together form a herringbone pattern (resembling the fish anatomy#Vertebrae, bones of a fish such as a herring). Unlike helical gears, herringbone gears do not produce an additional axial load. Like helical gears, they have the advantage of transferring power smoothly, because more than two teeth will be enmeshed at any moment in time. Their advantage over the helical gears is that the side-thrust of one half is balanced by that of the other half. This means that herringbone gears can be used in torque gearboxes without requiring a substantial thrust bearing. Because of this, herringbone gears were an important step in the introduction of the steam turbine to marine propul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid

In physics, a fluid is a liquid, gas, or other material that continuously deforms (''flows'') under an applied shear stress, or external force. They have zero shear modulus, or, in simpler terms, are substances which cannot resist any shear force applied to them. Although the term ''fluid'' generally includes both the liquid and gas phases, its definition varies among branches of science. Definitions of ''solid'' vary as well, and depending on field, some substances can be both fluid and solid. Viscoelastic fluids like Silly Putty appear to behave similar to a solid when a sudden force is applied. Substances with a very high viscosity such as pitch appear to behave like a solid (see pitch drop experiment) as well. In particle physics, the concept is extended to include fluidic matters other than liquids or gases. A fluid in medicine or biology refers any liquid constituent of the body (body fluid), whereas "liquid" is not used in this sense. Sometimes liquids given for flui ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Positive Displacement Pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: ''direct lift'', ''displacement'', and ''gravity'' pumps. Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis. When a casing contains only one revolving impeller, it is called a single-stage pump. When ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Pump Animation

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic principle behind the operation of gears is analogous to the basic principle of levers. A gear may also be known informally as a cog. Geared devices can change the speed, torque, and direction of a power source. Gears of different sizes produce a change in torque, creating a mechanical advantage, through their ''gear ratio'', and thus may be considered a simple machine. The rotational speeds, and the torques, of two meshing gears differ in proportion to their diameters. The teeth on the two meshing gears all have the same shape. Two or more meshing gears, working in a sequence, are called a gear train or a '' transmission''. The gears in a transmission are analogous to the wheels in a crossed, belt pulley system. An advantage of gears is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water. Viscosity quantifies the internal frictional force between adjacent layers of fluid that are in relative motion. For instance, when a viscous fluid is forced through a tube, it flows more quickly near the tube's axis than near its walls. Experiments show that some stress (such as a pressure difference between the two ends of the tube) is needed to sustain the flow. This is because a force is required to overcome the friction between the layers of the fluid which are in relative motion. For a tube with a constant rate of flow, the strength of the compensating force is proportional to the fluid's viscosity. In general, viscosity depends on a fluid's state, such as its temperature, pressure, and rate of deformation. However, the dependence on some of these properties is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)