|

Gas Cabinet

A gas cabinet is a metallic enclosure which is used to provide local exhaust ventilation system for virtually all of the gases used or generated in the semiconductor, solar, MEMS, NANO, solar PV, manufacturing and other advanced technologies. The primary purpose of gas cabinets is to contain potential leaks in piping and fittings at the cylinder connection. The cabinet must be exhausted by a specifically designed fan and exhaust system. The cabinet exhaust system draws leaking hazardous gasses out of the cabinet. In the case of a flammable gas the cabinet will contain the flame for a period of time. One can use a newly reconditioned cabinet as well as non-reconditioned used gas cabinets depending on their requirements. Features There are a variety of gas cabinets available in the market in different gas cylinder configurations, such as 1, 2 and 3 bottle designs. They can be either new, used, or reconditioned. A gas cylinder cabinet can have many features depending on the specif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photos Gas Cabinet Inventory

A photograph (also known as a photo, image, or picture) is an image created by light falling on a photosensitive surface, usually photographic film or an electronic image sensor, such as a CCD or a CMOS chip. Most photographs are now created using a smartphone/camera, which uses a lens to focus the scene's visible wavelengths of light into a reproduction of what the human eye would see. The process and practice of creating such images is called photography. Etymology The word ''photograph'' was coined in 1839 by Sir John Herschel and is based on the Greek φῶς (''phos''), meaning "light," and γραφή (''graphê''), meaning "drawing, writing," together meaning "drawing with light." History The first permanent photograph, a contact-exposed copy of an engraving, was made in 1822 using the bitumen-based "heliography" process developed by Nicéphore Niépce. The first photographs of a real-world scene, made using a camera obscura, followed a few years later at Le Gras, Fra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

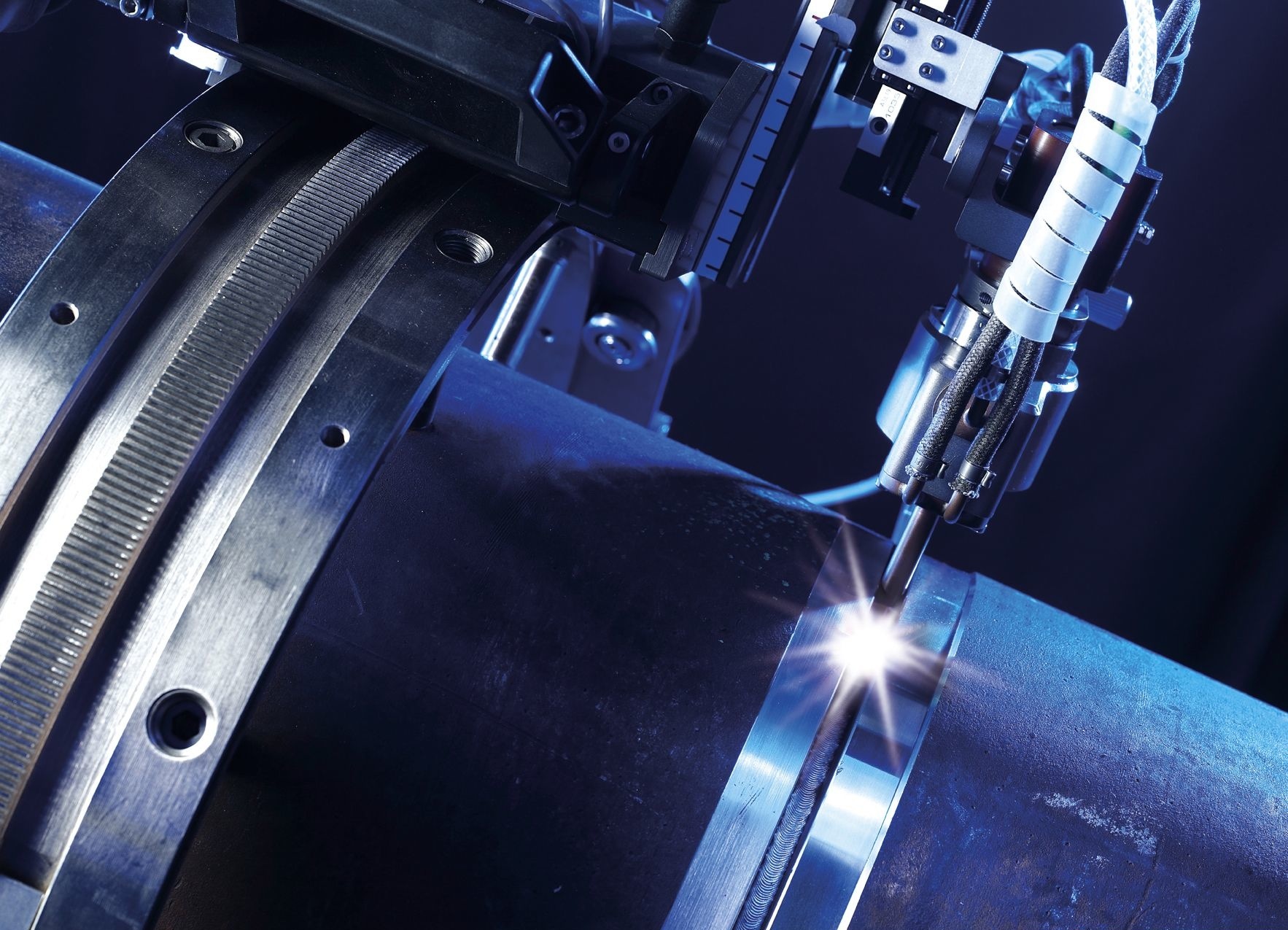

Orbital Welding

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically through 360° (180 degrees in double up welding) around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to address the issue of operator error in gas tungsten arc welding processes (GTAW), to support uniform welding around a pipe that would be significantly more difficult using a manual welding process, and to ensure high quality repeatable welds that would meet more stringent weld criteria set by ASME. In orbital welding, computer-controlled process runs with little intervention from the operator. History The orbital welding process was invented by Rodrick Rohrberg of North American Aviation to address fuel and hydraulic fluids leaking in and around the plumbing of the X-15 Rocket Research plane. Equipment The main components of every orbital welding system are the power supply with integrated computer control, the welding head and, where requ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scrubber

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. An early application of a carbon dioxide scrubber was in the submarine the ''Ictíneo I'', in 1859; a role for which they continue to be used today. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term has also been used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation.On Flue gas Condensa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bottled Gas

Bottled gas is a term used for substances which are gaseous at standard temperature and pressure (STP) and have been compressed and stored in carbon steel, stainless steel, aluminum, or composite bottles known as gas cylinders. Gas state in cylinders There are four cases: either the substance remains a gas at standard temperature but increased pressure, the substance liquefies at standard temperature but increased pressure, the substance is dissolved in a solvent, or the substance is liquefied at reduced temperature and increased pressure. In the last case the bottle is constructed with an inner and outer shell separated by a vacuum (dewar flask) so that the low temperature can be maintained by evaporative cooling. Case I The substance remains a ''gas'' at ''standard temperature'' and ''increased pressure'', its critical temperature being below standard temperature. Examples include: * air * argon * fluorine * helium * hydrogen * krypton * nitrogen * oxygen Case II The subs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications. The binding polymer is often a thermoset resin such as epoxy, but other thermoset or thermoplastic polymers, such as polyester, vinyl ester, or nylon, are sometimes used. The properties of the final CFRP product can be affected by the type of additives introduced to the binding matrix (resin). The most common additive is silica, but other addi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Overwrapped Pressure Vessel

A composite overwrapped pressure vessel (COPV) is a vessel consisting of a thin, non-structural liner wrapped with a structural fiber composite, designed to hold a fluid under pressure. The liner provides a barrier between the fluid and the composite, preventing leaks (which can occur through matrix microcracks which do not cause structural failure) and chemical degradation of the structure. In general, a protective shell is applied for protective shielding against impact damage. The most commonly used composites are fiber reinforced polymers (FRP), using carbon and kevlar fibers. The primary advantage of a COPV as compared to a similar sized metallic pressure vessel is lower weight; COPVs, however, carry an increased cost of manufacturing and certification. Overview A composite overwrapped pressure vessel (COPV) is a pressure-containing vessel, typically composed of a metallic liner, a composite overwrap, and one or more bosses. They are used in spaceflight due to their high ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filling Carousel

A filling carousel is intended for filling large quantities of liquefied petroleum gas (LPG) cylinders. It consists of a frame with running wheels, rails, a central column for LPG and air, and a driving unit the carousel frame around the central column. The speed of the carousel can be adapted to the various filling times and capacities. The dimension of the carousel is important to consider for the future filling capacity. The carousel frame chosen can be equipped with a number of filling scales, selected for the present demand and possible future demands. Filling carousels can be provided with equipment for automatic introduction and automatic filling scales with ejection of cylinders. Dimensions Frame sizes and approximate filling times for 12 kg cylinders with two-man operation: Associated equipment References Liquefied petroleum gas Industrial automation {{Engineering-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Gas

Industrial gases are the gaseous materials that are manufactured for use in industry. The principal gases provided are nitrogen, oxygen, carbon dioxide, argon, hydrogen, helium and acetylene, although many other gases and mixtures are also available in gas cylinders. The industry producing these gases is also known as industrial gas, which is seen as also encompassing the supply of equipment and technology to produce and use the gases. Their production is a part of the wider chemical Industry (where industrial gases are often seen as "specialty chemicals"). Industrial gases are used in a wide range of industries, which include oil and gas, petrochemicals, chemicals, power, mining, steelmaking, metals, environmental protection, medicine, pharmaceuticals, biotechnology, food, water, fertilizers, nuclear power, electronics and aerospace. Industrial gas is sold to other industrial enterprises; typically comprising large orders to corporate industrial clients, covering a size range fr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Storage Tank

Storage tanks are containers that hold liquids, compressed gases (gas tank; or in U.S.A "pressure vessel", which is not typically labeled or regulated as a storage tank) or mediums used for the short- or long-term storage of heat or cold. The term can be used for reservoirs (artificial lakes and ponds), and for manufactured containers. The usage of the word tank for reservoirs is uncommon in American English but is moderately common in British English. In other countries, the term tends to refer only to artificial containers. In the USA, storage tanks operate under no (or very little) pressure, distinguishing them from ''pressure vessels''. Storage tanks are often cylindrical in shape, perpendicular to the ground with flat bottoms, and a fixed frangible or floating roof. There are usually many environmental regulations applied to the design and operation of storage tanks, often depending on the nature of the fluid contained within. Above-ground storage tanks (ASTs) differ from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

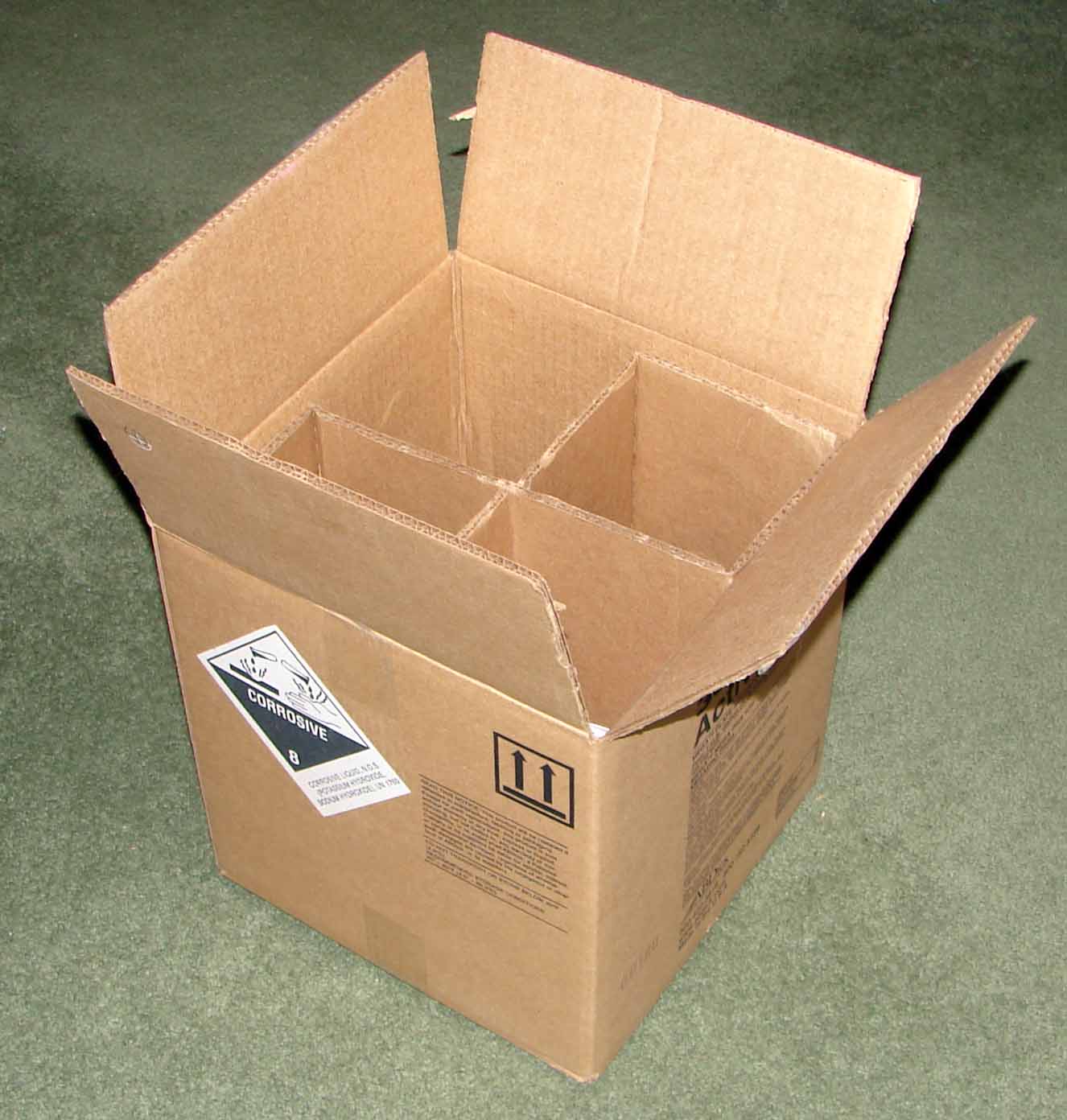

UN Recommendations On The Transport Of Dangerous Goods

The ''UN Recommendations on the Transport of Dangerous Goods'' are contained in thprepared by the Subcommittee of Experts on the Transport of Dangerous Goods of the United Nations Economic and Social Council (ECOSOC). They cover the transport of dangerous goods by all modes of transport except by bulk tanker. They are not obligatory or legally binding on individual countries, but have gained a wide degree of international acceptance: they form the basis of several international agreements and many national laws. "Dangerous goods" (also known as "hazardous materials" or "HAZMAT" in the United States) may be a pure chemical substance (for example, trinitrotoluene (TNT), nitroglycerin), mixtures (for example, dynamite, gunpowder) or manufactured articles (for example, ammunition, fireworks). The transport hazards that they pose are grouped into nine classes, which may be subdivided into divisions and/or packing groups. The most common dangerous goods are assigned a UN number, a fou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Container

A fuel container is a container such as a steel can, bottle, drum, etc. for transporting, storing, and dispensing various fuels. Construction A wide variety of container types and constructions are used for fuels. Each has its own engineering challenges. The jerrycan is a robust liquid container originally made from pressed steel. It was designed in Germany in the 1930s for military use to hold 20 litres (4.4 imp gal; 5.3 US gal) of fuel. Three handles allow for two people carrying a full can or one person handling an empty can. The basic design is still in use today although construction is often of high density polyethylene. Portable plastic gasoline containers are commercially available and are in common use. These are usually blow molded polyethylene or other polymers compatible with the designated fuel. It has been found that the use of flame arresters reduces the chance of fire or explosion of gasoline. Child resistant caps or closures are re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |