|

Factor Of Safety

In engineering, a factor of safety (FoS), also known as (and used interchangeably with) safety factor (SF), expresses how much stronger a system is than it needs to be for an intended load. Safety factors are often calculated using detailed analysis because comprehensive testing is impractical on many projects, such as bridges and buildings, but the structure's ability to carry a load must be determined to a reasonable accuracy. Many systems are intentionally built much stronger than needed for normal usage to allow for emergency situations, unexpected loads, misuse, or degradation (reliability). Definition There are two definitions for the factor of safety (FoS): * The ratio of a structure's absolute strength (structural capability) to actual applied load; this is a measure of the reliability of a particular design. This is a calculated value, and is sometimes referred to, for the sake of clarity, as a ''realized factor of safety''. * A constant required value, imposed by law, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reliability Engineering

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time. The reliability function is theoretically defined as the probability of success at time t, which is denoted R(t). This probability is estimated from detailed (physics of failure) analysis, previous data sets or through reliability testing and reliability modelling. Availability, testability, maintainability and maintenance are often defined as a part of "reliability engineering" in reliability programs. Reliability often plays the key role in the cost-effectiveness of systems. Reliability engineering deals with the prediction, prevention and man ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they wer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerospace Engineering

Aerospace engineering is the primary field of engineering concerned with the development of aircraft and spacecraft. It has two major and overlapping branches: aeronautical engineering and astronautical engineering. Avionics engineering is similar, but deals with the electronics side of aerospace engineering. "Aeronautical engineering" was the original term for the field. As flight technology advanced to include vehicles operating in outer space, the broader term "aerospace engineering" has come into use. Aerospace engineering, particularly the astronautics branch, is often colloquially referred to as "rocket science". Overview Flight vehicles are subjected to demanding conditions such as those caused by changes in atmospheric pressure and temperature, with structural loads applied upon vehicle components. Consequently, they are usually the products of various technological and engineering disciplines including aerodynamics, Air propulsion, avionics, materials science, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Redundancy (engineering)

In engineering, redundancy is the intentional duplication of critical components or functions of a system with the goal of increasing reliability of the system, usually in the form of a backup or fail-safe, or to improve actual system performance, such as in the case of GNSS receivers, or multi-threaded computer processing. In many safety-critical systems, such as fly-by-wire and hydraulic systems in aircraft, some parts of the control system may be triplicated, which is formally termed triple modular redundancy (TMR). An error in one component may then be out-voted by the other two. In a triply redundant system, the system has three sub components, all three of which must fail before the system fails. Since each one rarely fails, and the sub components are expected to fail independently, the probability of all three failing is calculated to be extraordinarily small; it is often outweighed by other risk factors, such as human error. Redundancy may also be known by the te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Failure Mode And Effects Analysis

Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. For each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific FMEA worksheet. There are numerous variations of such worksheets. An FMEA can be a qualitative analysis, but may be put on a quantitative basis when mathematical failure rate models are combined with a statistical failure mode ratio database. It was one of the first highly structured, systematic techniques for failure analysis. It was developed by reliability engineers in the late 1950s to study problems that might arise from malfunctions of military systems. An FMEA is often the first step of a system reliability study. A few different types of FMEA analyses exist, such as: * Functional * Design * Process Sometimes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Risk Analysis (engineering)

Risk analysis is the science of risks and their probability and evaluation. Probabilistic risk assessment is one analysis strategy usually employed in science and engineering. In a probabilistic risk assessment risks are identified and then assessed in terms of likelihood of occurrence of a consequence and the magnitude of a potential consequence. Risk analysis and the risk workshop Risk analysis should be performed as part of the risk management process for each project. The data of which would be based on risk discussion workshops to identify potential issues and risks ahead of time before these were to pose cost and/ or schedule negative impacts (see the article on cost contingency for a discussion of the estimation of cost impacts). The risk workshops should be attended by a large group, ideally between six and ten individuals from the various departmental functions (e.g. project manager, construction manager, site superintendent, and representatives from operations, p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Environment (systems)

In science and engineering, a system is the part of the universe that is being studied, while the environment is the remainder of the universe that lies outside the boundaries of the system. It is also known as the surroundings or neighborhood, and in thermodynamics, as the reservoir. Depending on the type of system, it may interact with the environment by exchanging mass, energy (including heat and work), linear momentum, angular momentum, electric charge, or other conserved properties. In some disciplines, such as information theory, information may also be exchanged. The environment is ignored in analysis of the system, except in regard to these interactions. See also * Bioenergetic systems - energy system * Earth system science * Environment (biophysical) * Environmental Management System *Thermodynamic system A thermodynamic system is a body of matter and/or radiation, confined in space by walls, with defined permeabilities, which separate it from its surroundings ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1-4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected by f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Structural Load

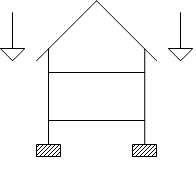

A structural load or structural action is a force, deformation, or acceleration applied to structural elements. A load causes stress, deformation, and displacement in a structure. Structural analysis, a discipline in engineering, analyzes the effects of loads on structures and structural elements. Excess load may cause structural failure, so this should be considered and controlled during the design of a structure. Particular mechanical structures—such as aircraft, satellites, rockets, space stations, ships, and submarines—are subject to their own particular structural loads and actions. Engineers often evaluate structural loads based upon published regulations, contract A contract is a legally enforceable agreement between two or more parties that creates, defines, and governs mutual rights and obligations between them. A contract typically involves the transfer of goods, services, money, or a promise to ...s, or specifications. Accepted technical standards a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Accuracy

Accuracy and precision are two measures of '' observational error''. ''Accuracy'' is how close a given set of measurements (observations or readings) are to their '' true value'', while ''precision'' is how close the measurements are to each other. In other words, ''precision'' is a description of ''random errors'', a measure of statistical variability. ''Accuracy'' has two definitions: # More commonly, it is a description of only ''systematic errors'', a measure of statistical bias of a given measure of central tendency; low accuracy causes a difference between a result and a true value; ISO calls this ''trueness''. # Alternatively, ISO defines accuracy as describing a combination of both types of observational error (random and systematic), so high accuracy requires both high precision and high trueness. In the first, more common definition of "accuracy" above, the concept is independent of "precision", so a particular set of data can be said to be accurate, precise, both, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a sharp snapping sound. When used in materials science, it is generally applied to materials that fail when there is little or no plastic deformation before failure. One proof is to match the broken halves, which should fit exactly since no plastic deformation has occurred. Brittleness in different materials Polymers Mechanical characteristics of polymers can be sensitive to temperature changes near room temperatures. For example, poly(methyl methacrylate) is extremely brittle at temperature 4˚C, but experiences increased ductility with increased temperature. Amorphous polymers are polymers that can behave differently at different temperatures. They may behave like a glass at low temperatures (the glas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)