|

Endothermic Gas

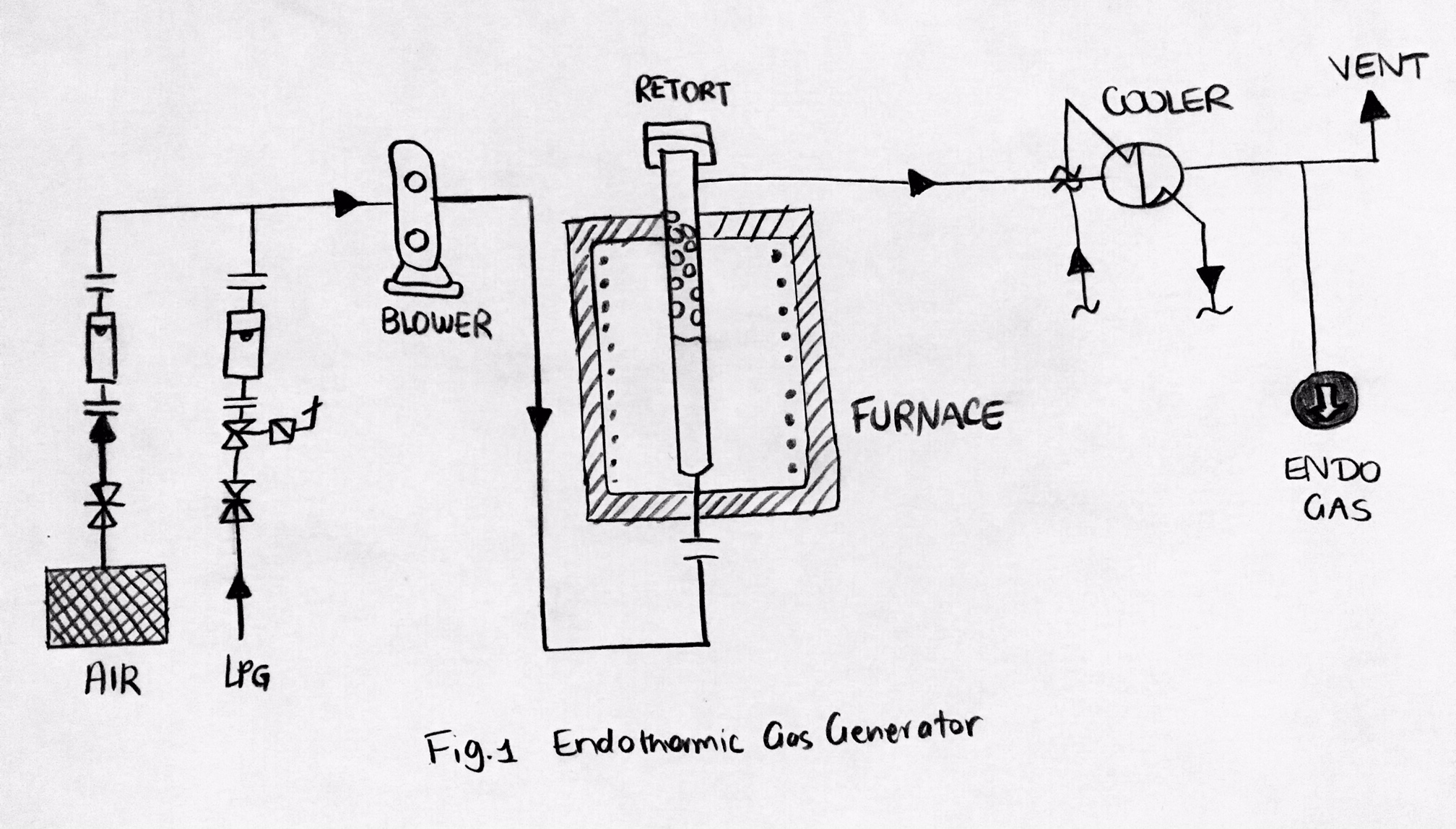

Endothermic gas is a gas that inhibits or reverses oxidation on the surfaces it is in contact with. This gas is the product of incomplete combustion in a controlled environment. An example mixture is hydrogen gas (H2), nitrogen gas (N2), and carbon monoxide (CO). The hydrogen and carbon monoxide are reducing agents, so they work together to shield surfaces from oxidation. Endothermic gas is often used as a carrier gas for gas carburizing and carbonitriding. An endothermic gas generator could be used to supply heat to form an endothermic reaction. Synthesised in the catalytic retort(s) of endothermic generators, the gas in the endothermic atmosphere is combined with an additive gas including natural gas, propane (C3H8) or air and is then used to improve the surface chemistry work positioned in the furnace. Purposes There are two common purposes of the atmospheres in the heat treating industry: # Protect the processed material from surface reactions (chemically inert) # Allow ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Endothermic

In thermochemistry, an endothermic process () is any thermodynamic process with an increase in the enthalpy (or internal energy ) of the system.Oxtoby, D. W; Gillis, H.P., Butler, L. J. (2015).''Principle of Modern Chemistry'', Brooks Cole. p. 617. In such a process, a closed system usually absorbs thermal energy from its surroundings, which is heat transfer into the system. Thus, an endothermic reaction generally leads to an increase in the temperature of the system and a decrease in that of the surroundings. It may be a chemical process, such as dissolving ammonium nitrate () in water (), or a physical process, such as the melting of ice cubes. The term was coined by 19th-century French chemist Marcellin Berthelot. The opposite of an endothermic process is an exothermic process, one that releases or "gives out" energy, usually in the form of heat and sometimes as electrical energy. Thus in each term (endothermic and exothermic) the prefix refers to where heat (or electrical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usually gaseous or liquid) as the reactant, or heterogeneous, whose components are not in the same phase. Enzymes and other biocatalysts are often considered as a third category. Catalysis is ubiquitous in chemical industry of all kinds. Estimates are that 90% of all commercially produced chemical products involve catalysts at some s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forming Gas

Forming gas is a mixture of hydrogen (mole fraction varies) and nitrogen. It is sometimes called a "dissociated ammonia atmosphere" due to the reaction which generates it: :2 NH3 → 3 H2 + N2 It can also be manufactured by thermal cracking of ammonia, in an ammonia cracker or forming gas generator. Forming gas is used as an atmosphere for processes that need the properties of hydrogen gas. Typical forming gas formulations (5% H2 in N2) are not explosive. It is used in chambers for gas hypersensitization, a process in which photographic film is heated in forming gas to drive out moisture and oxygen and to increase the base fog of the film. Hypersensitization is used particularly in deep-sky astrophotography, which deals with low-intensity incoming light, requires long exposure times, and is thus particularly sensitive to contaminants in the film. Forming gas is also used to regenerate catalysts in glove boxes and as an atmosphere for annealing processes. It can be pu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitrocarburizing

Ferritic nitrocarburizing or FNC, also known by the proprietary names Tenifer, Tufftride and Melonite as well as ARCOR,Other trade names include Tuffride/ Tuffrider, QPQ, Sulfinuz, Sursulf, Meli 1, and Nitride, among others is a range of proprietary case hardening processes that diffuse nitrogen and carbon into ferrous metals at sub-critical temperatures during a salt bath. Other methods of ferric nitrocarburizing include gaseous process such as Nitrotec and ion (plasma) ones. The processing temperature ranges from to , but usually occurs at . At this temperature steels and other ferrous alloys remain in the Allotropes_of_iron#Alpha_iron_(α-Fe), ferritic phase region. This allows for better control of the dimensional stability that would not be present in case hardening processes that occur when the alloy is transitioned into the austenitic phase.. There are four main classes of ferritic nitrocarburizing: ''gaseous'', ''salt bath'', ''ion'' or ''plasma'', and ''fluidized-bed''.. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brazing

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts than when soldering. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. A major advantage of brazing is the ability to join the same or different metals with considerable strength. Basics High-quality brazed joints require that parts be closely fitted with base m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annealing (materials Science)

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling. In annealing, atoms migrate in the crystal lattice and the number of dislocations decreases, leading to a change in ductility and hardness. As the material cools it recrystallizes. For many alloys, including carbon steel, the crystal grain size and phase composition, which ultimately determine the material properties, are dependent on the heating rate and cooling rate. Hot working or cold working after the annealing process alters the metal structure, so further heat treatments may be used to achieve the properties required. With knowledge of the composition and phase diagram, heat treatment can be used to adj ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dew Point

The dew point is the temperature to which air must be cooled to become saturated with water vapor, assuming constant air pressure and water content. When cooled below the dew point, moisture capacity is reduced and airborne water vapor will condense to form liquid water known as dew. When this occurs via contact with a colder surface, dew will form on that surface. The dew point is affected by humidity. When there is more moisture in the air, the dew point is higher. When the temperature is below the freezing point of water, the dew point is called the frost point, as frost is formed via deposition rather than condensation. In liquids, the analog to the dew point is the cloud point. Humidity If all the other factors influencing humidity remain constant, at ground level the relative humidity rises as the temperature falls; this is because less vapor is needed to saturate the air. In normal conditions, the dew point temperature will not be greater than the air temperature, sinc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |