|

Eigenstrain

In continuum mechanics an eigenstrain is any mechanical deformation in a material that is not caused by an external mechanical stress, with thermal expansion often given as a familiar example. The term was coined in the 1970s by Toshio Mura, who worked extensively on generalizing their mathematical treatment. A non-uniform distribution of eigenstrains in a material (e.g., in a composite material) leads to corresponding eigenstresses, which affect the mechanical properties of the material. Overview Many distinct physical causes for eigenstrains exist, such as crystallographic defects, thermal expansion, the inclusion of additional phases in a material, and previous plastic strains. All of these result from internal material characteristics, not from the application of an external mechanical load. As such, eigenstrains have also been referred to as “stress-free strains” and “inherent strains”. When one region of material experiences a different eigenstrain than its surro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Expansion

Thermal expansion is the tendency of matter to change its shape, area, volume, and density in response to a change in temperature, usually not including phase transitions. Temperature is a monotonic function of the average molecular kinetic energy of a substance. When a substance is heated, molecules begin to vibrate and move more, usually creating more distance between themselves. Substances which contract with increasing temperature are unusual, and only occur within limited temperature ranges (see examples below). The relative expansion (also called strain) divided by the change in temperature is called the material's coefficient of linear thermal expansion and generally varies with temperature. As energy in particles increases, they start moving faster and faster weakening the intermolecular forces between them, therefore expanding the substance. Overview Predicting expansion If an equation of state is available, it can be used to predict the values of the thermal expan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuum Mechanics

Continuum mechanics is a branch of mechanics that deals with the mechanical behavior of materials modeled as a continuous mass rather than as discrete particles. The French mathematician Augustin-Louis Cauchy was the first to formulate such models in the 19th century. Explanation A continuum model assumes that the substance of the object fills the space it occupies. Modeling objects in this way ignores the fact that matter is made of atoms, and so is not continuous; however, on length scales much greater than that of inter-atomic distances, such models are highly accurate. These models can be used to derive differential equations that describe the behavior of such objects using physical laws, such as mass conservation, momentum conservation, and energy conservation, and some information about the material is provided by constitutive relationships. Continuum mechanics deals with the physical properties of solids and fluids which are independent of any particular coordinate sy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deformation (mechanics)

In physics, deformation is the continuum mechanics transformation of a body from a ''reference'' configuration to a ''current'' configuration. A configuration is a set containing the positions of all particles of the body. A deformation can occur because of external loads, intrinsic activity (e.g. muscle contraction), body forces (such as gravity or electromagnetic forces), or changes in temperature, moisture content, or chemical reactions, etc. Strain is related to deformation in terms of ''relative'' displacement of particles in the body that excludes rigid-body motions. Different equivalent choices may be made for the expression of a strain field depending on whether it is defined with respect to the initial or the final configuration of the body and on whether the metric tensor or its dual is considered. In a continuous body, a deformation field results from a stress field due to applied forces or because of some changes in the temperature field of the body. The rel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toshio Mura

was a professor of engineering. He was born in Ono, a small port village of Kanazawa Japan, on December 7, 1925. He received a doctorate in the Department of Applied Mathematics of the University of Tokyo in 1954. He taught at Meiji University, Japan from 1954 to 1958. In 1958, he went to the United States to work in the Department of Materials Science at Northwestern University in Evanston, Illinois. He became a professor in the Department of Civil Engineering in 1966 before his retirement in 1996, and also held an appointment in the Department of Mechanical Engineering. Dr. Mura was appointed Walter P. Murphy Professor in the McCormick School of Engineering at Northwestern, was elected as a member of the National Academy of Engineering (NAE) in 1986 for his contributions to the field of micromechanics, and received many other accolades for his work. He was as much recognized for his academic achievement as his generosity in opening his home to visiting scholars and graduat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites ( composite ceramic and metal matrices) *Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystallographic Defects

A crystallographic defect is an interruption of the regular patterns of arrangement of atoms or molecules in crystalline solids. The positions and orientations of particles, which are repeating at fixed distances determined by the unit cell parameters in crystals, exhibit a periodic crystal structure, but this is usually imperfect.Ehrhart, P. (1991Properties and interactions of atomic defects in metals and alloys, volume 25 of Landolt-Börnstein, New Series III, chapter 2, p. 88, Springer, Berlin Several types of defects are often characterized: point defects, line defects, planar defects, bulk defects. Topological homotopy establishes a mathematical method of characterization. Point defects Point defects are defects that occur only at or around a single lattice point. They are not extended in space in any dimension. Strict limits for how small a point defect is are generally not defined explicitly. However, these defects typically involve at most a few extra or missing atoms. Lar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residual Stress

In materials science and solid mechanics, residual stresses are Stress (physics), stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to Catastrophic failure, fail prematurely. Residual stresses can result from a variety of mechanisms including inelastic (Plasticity (physics), plastic) Deformation (engineering), deformations, temperature gradients (during thermal cycle) or structural changes (phase transformation). Heat from welding may cause localized expansion, which is taken up during welding by either the molten metal or the placement of parts being welde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Elasticity

Linear elasticity is a mathematical model of how solid objects deform and become internally stressed due to prescribed loading conditions. It is a simplification of the more general nonlinear theory of elasticity and a branch of continuum mechanics. The fundamental "linearizing" assumptions of linear elasticity are: infinitesimal strains or "small" deformations (or strains) and linear relationships between the components of stress and strain. In addition linear elasticity is valid only for stress states that do not produce yielding. These assumptions are reasonable for many engineering materials and engineering design scenarios. Linear elasticity is therefore used extensively in structural analysis and engineering design, often with the aid of finite element analysis. Mathematical formulation Equations governing a linear elastic boundary value problem are based on three tensor partial differential equations for the balance of linear momentum and six infinitesimal strain- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Einstein Notation

In mathematics, especially the usage of linear algebra in Mathematical physics, Einstein notation (also known as the Einstein summation convention or Einstein summation notation) is a notational convention that implies summation over a set of indexed terms in a formula, thus achieving brevity. As part of mathematics it is a notational subset of Ricci calculus; however, it is often used in physics applications that do not distinguish between tangent and cotangent spaces. It was introduced to physics by Albert Einstein in 1916. Introduction Statement of convention According to this convention, when an index variable appears twice in a single term and is not otherwise defined (see Free and bound variables), it implies summation of that term over all the values of the index. So where the indices can range over the set , : y = \sum_^3 c_i x^i = c_1 x^1 + c_2 x^2 + c_3 x^3 is simplified by the convention to: : y = c_i x^i The upper indices are not exponents but are indices ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hooke’s Law

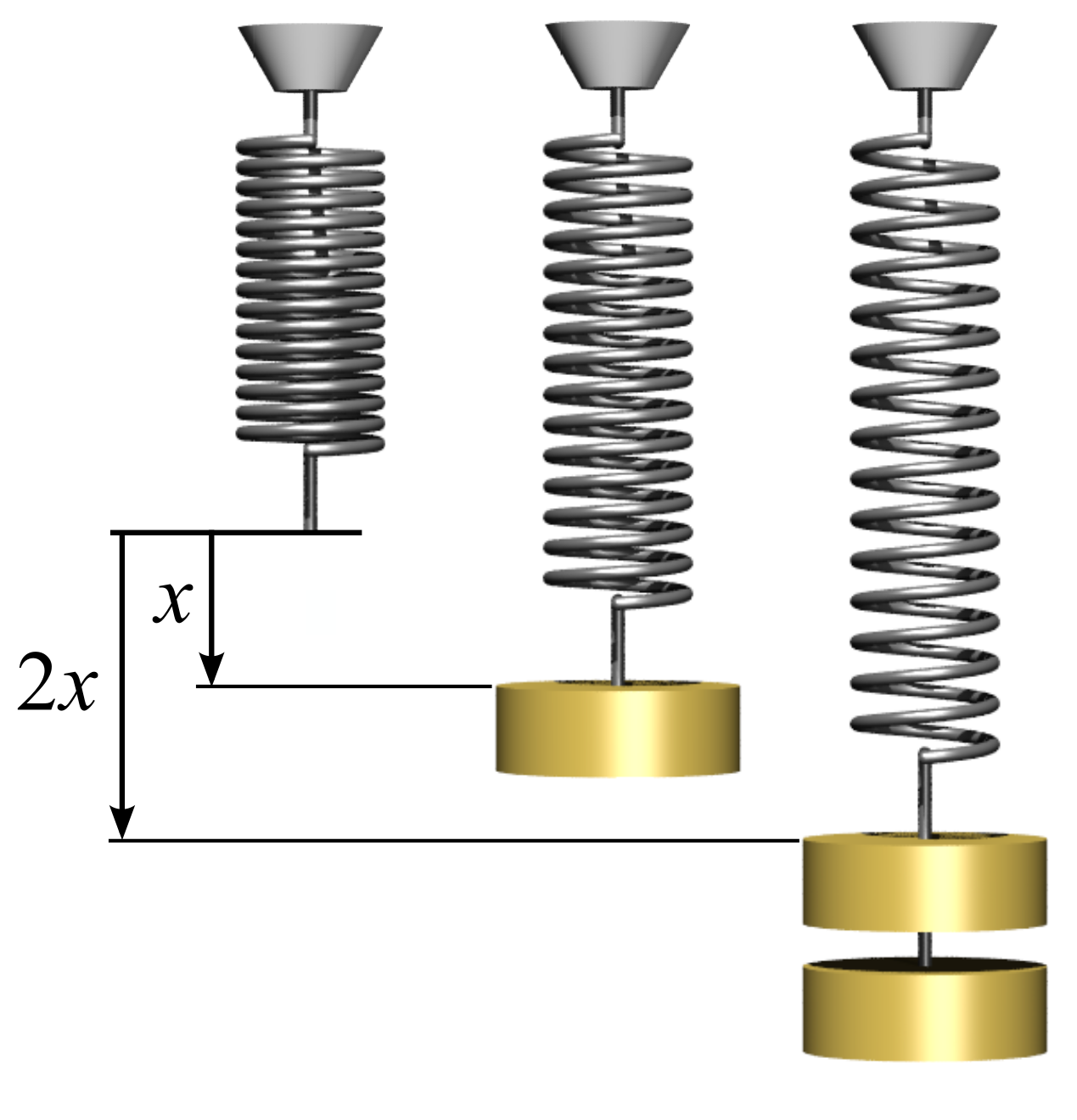

In physics, Hooke's law is an empirical law which states that the force () needed to extend or compress a spring by some distance () scales linearly with respect to that distance—that is, where is a constant factor characteristic of the spring (i.e., its stiffness), and is small compared to the total possible deformation of the spring. The law is named after 17th-century British physicist Robert Hooke. He first stated the law in 1676 as a Latin anagram. He published the solution of his anagram in 1678 as: ("as the extension, so the force" or "the extension is proportional to the force"). Hooke states in the 1678 work that he was aware of the law since 1660. Hooke's equation holds (to some extent) in many other situations where an elastic body is deformed, such as wind blowing on a tall building, and a musician plucking a string of a guitar. An elastic body or material for which this equation can be assumed is said to be linear-elastic or Hookean. Hooke's law is on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ellipsoidal Eigenstrain Inclusion

An ellipsoid is a surface that may be obtained from a sphere by deforming it by means of directional scalings, or more generally, of an affine transformation. An ellipsoid is a quadric surface; that is, a surface that may be defined as the zero set of a polynomial of degree two in three variables. Among quadric surfaces, an ellipsoid is characterized by either of the two following properties. Every planar cross section is either an ellipse, or is empty, or is reduced to a single point (this explains the name, meaning "ellipse-like"). It is bounded, which means that it may be enclosed in a sufficiently large sphere. An ellipsoid has three pairwise perpendicular axes of symmetry which intersect at a center of symmetry, called the center of the ellipsoid. The line segments that are delimited on the axes of symmetry by the ellipsoid are called the ''principal axes'', or simply axes of the ellipsoid. If the three axes have different lengths, the figure is a triaxial ellipsoid (ra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residual Stress

In materials science and solid mechanics, residual stresses are Stress (physics), stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to Catastrophic failure, fail prematurely. Residual stresses can result from a variety of mechanisms including inelastic (Plasticity (physics), plastic) Deformation (engineering), deformations, temperature gradients (during thermal cycle) or structural changes (phase transformation). Heat from welding may cause localized expansion, which is taken up during welding by either the molten metal or the placement of parts being welde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |